This month, The Steel Wire has detailed some of the barriers facing automakers to make cars lighter, safer, and more affordable. While these qualities are typically mutually exclusive (safer cars are usually heavier, and lighter vehicles typically need more expensive lightweight materials), POSCO GIGA STEEL can provide all of these benefits to manufacturers in one product. It is strong and formable, lightweight and affordable. However, POSCO does more than simply provide high-quality products.

POSCO knows that car manufacturers must deal with unexpected issues during the production process. So, POSCO has expanded its services with Solution Marketing 2.0 in order to provide the application technology and commercial support that customers need. From planning to production, POSCO works hand-in-hand to ensure shorter processing times that move customers to mass production more efficiently.

History of Solution Marketing

Early Vendor Involvement (EVI)

In 2007, POSCO introduced its early vendor involvement (EVI) program. EVI allowed POSCO to participate in the customer’s product development stages, providing support for application technologies needed during manufacturing as well as in performance evaluation of the steel material. In 2014, POSCO expanded its EVI program with the implementation of the more advanced Solution Marketing.

Solution Marketing

With Solution Marketing, POSCO goes one step beyond its steel production to provide customers with the technological, commercial, and human resources support they need. With a focus on developing better relationships with customers, CEO Ohjoon Kwon has emphasized that “Solution Marketing should evolve into human solutions in which customers benefit from the expertise and relationships of POSCO’s dedicated employees.” Since 2014, sales of products combined with Solution Marketing have tripled, and sales of POSCO’s World Premium Products have increased by 56%.

Solution Marketing 2.0

In 2017, POSCO is launching Solution Marketing 2.0 to provide even better support to its customers. Solution Marketing 2.0 is driven by 3 core strategies:

- Innovate – by improving production speed, value, and standards

- Digitize – by providing highly advanced information technology

- Customize – by tailoring each solution to the client’s specific needs

These three strategies are specifically designed to put the customer’s success first and to help them understand the balance between a product’s features, price, and long-term benefits. Through POSCO’s Solution Marketing 2.0, customers are provided the tools they need to maximize convenience and efficiency in utilizing high-quality steel.

“We see POSCO’s success through the customer’s success. And we do not stop working until the customer is satisfied.” In-hwan Oh, President of POSCO

With Solution Marketing 2.0, this level of commitment is guaranteed to each client in every industry (see how Solution Marketing helped a pipe plant in Russia). For automotive manufacturers, Solution Marketing 2.0 helps streamline the production process and shorten setup time. Combined with POSCO GIGA STEEL, Solution Marketing 2.0 can help automakers manufacture higher quality, complex products in less time.

Solution Marketing for the Auto Industry

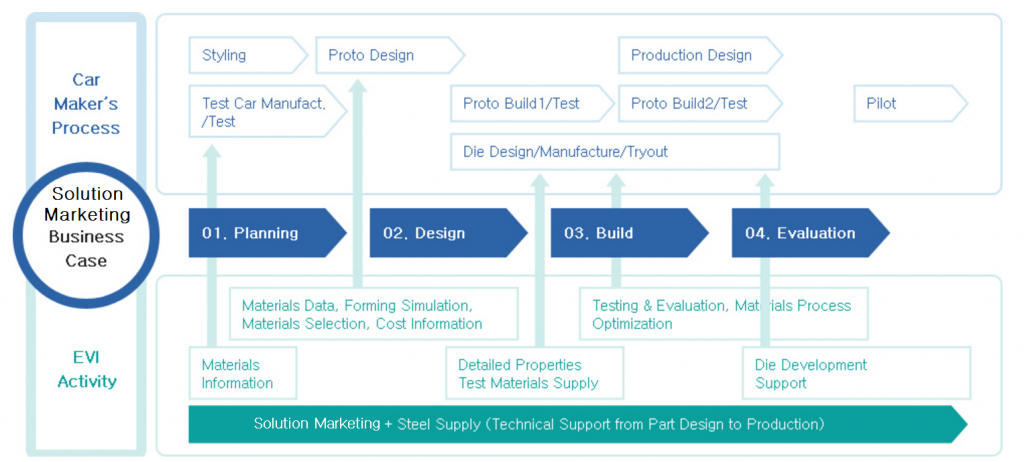

Solution Marketing for the automotive industry offers specialized support to clients in their setup process. The development process for automakers is composed of four steps: planning, design, building, and evaluation. Through each step of the process, POSCO works with customers to provide customized solutions, resulting in higher quality products and shortened production times. At POSCO China, Solution Marketing 2.0 provided automotive customers with the speed, value, and quality they needed to maximize convenience and efficiency for their production lines.

Step 1 – Planning

In deciding the car’s concept, design, and material of the car, POSCO provides information regarding the initial concept design including material properties and tear down results (including parts analysis after disassembly).

Step 2 – Design

The objective of step 2 is to confirm the design of the parts and the types of steels to be used. POSCO provides numerical simulations regarding collision safety, structural integrity, and formability in order to suggest final design concepts and applicable steels to clients.

Step 3 – Build

In step 3 the car is built with an eye toward mass production. Based on these results, POSCO provides the customer with a variety of guidelines on how to reduce defects while improving weldability. This helps the automaker apply improvements to the process and minimize manufacturing errors.

Step 4 – Evaluation

In the final step, the manufactured car and its parts are evaluated and assessed.

Evaluations on the car’s durability, structural stiffness, and crash performance can be provided. Also, corrosion and coating performance are analyzed in order the car manufacturer to make further enhancements for long-term performance.

For today’s auto manufacturers facing stricter standards in fuel efficiency and safety, POSCO GIGA STEEL offers the best solution to meet their needs. It offers superior strength and formability for manufacturers while also being lightweight and fuel efficient for consumers.

But POSCO’s commitment to auto manufacturers goes beyond providing advanced steel solutions. With Solution Marketing 2.0, POSCO works with customers from planning to production to ensure success.

Subscribe to our newsletter today throughout April and May as we highlight POSCO GIGA STEEL and more of POSCO’s unique automotive steel solutions.