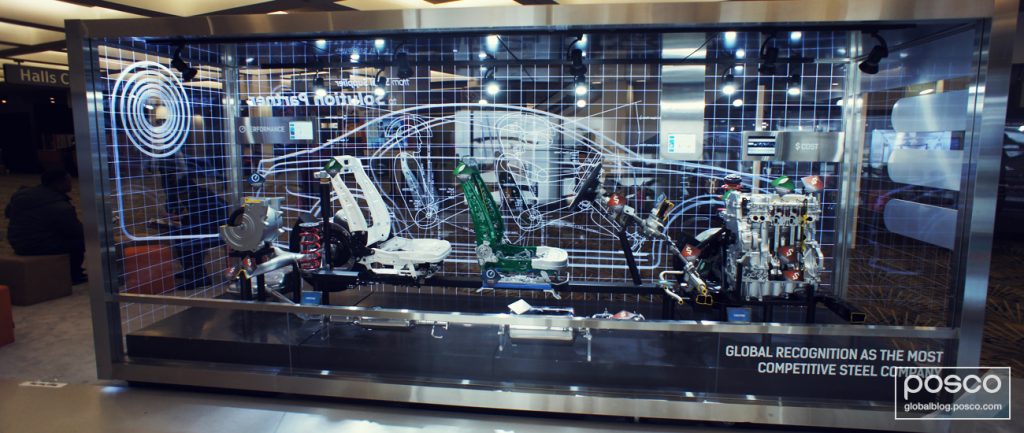

The auto industry is transforming itself to meet changing consumer demands and increasingly strict safety and fuel efficiency regulations. To do this, automakers are searching for materials that are both lighter and stronger so that they can build safer and more efficient cars. As the world’s fourth largest steelmaker, POSCO provides advanced steel solutions to meet these challenges.

POSCO’s innovations in steel technology have long supplied material solutions for the automotive industry. Last year, POSCO sold approximately 9 million tons of automotive steel sheets, accounting for 10% of the global automotive steel sheet market. In 2017, POSCO’s focus on providing customers with the most advanced, high-quality steel continues with POSCO GIGA STEEL.

POSCO GIGA STEEL, the Beginning of a New Era

POSCO GIGA STEEL represents the apex of steel technology as it is lightweight, strong, and highly formable – exactly what automakers are looking for. Innovations in POSCO’s manufacturing processes reduce both its production emissions and price, making it a more sustainable and affordable option for car makers compared to other lightweight materials. See how POSCO GIGA STEEL is opening a new era for automotive steel in the video below.

POSCO GIGA STEEL Provides Strength & Safety

Automotive steel is categorized according to its tensile strength. POSCO GIGA STEELS fall into the highest category, which includes steels with a tensile strength rated at more than 1 GPa (Gigapascal), meaning it can withstand more than 100 kilograms-force per square millimeter. In the past, steels with tensile strength ratings this high have been problematic for automakers as they had low ductility and elongation properties.

What makes POSCO GIGA STEEL the ideal material for automakers is its ability to both bend and withstand an immense amount of weight and pressure. POSCO’s ultra high strength giga steel has up to three times more formability than other types of comparable steel on the market, making it ideal for manufacturers.

A car’s safety can also be enhanced significantly when POSCO GIGA STEEL is applied to a vehicle’s BIW (body in white) or front and back bumpers. POSCO GIGA STEEL is not only strong but has exceptional shock absorption during impact.

The strength and safety of POSCO GIGA STEEL have been tested and proven to meet the industry’s strictest safety standards. The POSCO Body Concept-Electric Vehicle (PBC-EV) is a lightweight and safe car body for electric vehicles made with POSCO GIGA STEEL. In safety tests, it received “five stars” from the Europe New Car Assessment Program and a “good” rating from the Insurance Institute for Highway Safety (IIHS) – the highest ratings one can receive from both organizations.

POSCO GIGA STEEL Helps Deliver Lightweight & Sustainable Cars

Strict regulations on fuel efficiency and carbon emissions continue to push automakers to look for lighter materials to reduce the overall weight of vehicles. However, because stricter safety regulations typically require using heavier body parts, automakers are looking for both strong and light materials to build their cars. Lightweight solutions can be found in some alternative materials, such as aluminum and carbon fiber composites, but there are some drawbacks. For example, although POSCO GIGA STEEL is heavier than aluminum (when measuring equal parts area and thickness), it is more than three times stronger. Therefore, less of it is needed to manufacture products that are as light or lighter than those made with aluminum.

Car bodies manufactured with POSCO GIGA STEEL and other advanced high strength steels could see a 26% reduction in total weight when compared to cars of the same size with internal combustion engines. Considering that the average body weight of medium-sized cars in the early 2000’s was 280-300 kg, this is a remarkable achievement for automakers today.

Also, based on its life cycle assessment measuring carbon dioxide emissions from production to recycling, POSCO GIGA STEEL performs remarkably well as an eco-friendly material. According to the World Steel Association, steel emits 2.0 to 2.5 kg of carbon emissions when producing 1 kg of material while aluminum emits 11 to 12.6 kg when producing the same amount. Even after production, cumulative greenhouse gas emissions of vehicles made with steel is 10% lower when looking at the full life cycle.

POSCO GIGA STEEL Offers an Affordable Option

In automotive lightweighting, a reverse correlation often exists between price and weight. Lighter materials are typically more expensive and heavier materials usually have a lower price. POSCO GIGA STEEL helps bridge this gap by producing automotive steel that is both lightweight and cost-effective.

Body parts made of POSCO GIGA STEEL can see significant cost savings. Alternative materials like aluminum can cost anywhere from 2.1 to 3.5 times more than POSCO GIGA STEEL. Additionally, current market prices of alternative materials are not expected to decrease over the next ten years.

Facing increasingly strict regulations, POSCO GIGA STEEL offers an ideal choice for automakers to build stronger, lighter, and more sustainable cars. According to POSCO Research Institute (POSRI), advanced high-strength steels (AHSS) like POSCO GIGA STEEL should see increased demand, accounting for 69% of total steel plates by 2023.

Throughout April & May, The Steel Wire will explore how POSCO is leading the automotive steel market with its innovative steel products like POSCO GIGA STEEL. Don’t miss any of the exciting stories from The Steel Wire – subscribe via email today.

- advanced high strength steel

- AHSS

- aluminum

- auto manufacturers

- auto materials

- automaker

- automakers

- automobile expert

- automobile material

- automobile steel

- automotive industry

- automotive steel

- car manufacturer

- car steel

- carbon

- efficient cars

- fuel efficiency

- future cars

- giga steel

- high-strength steel

- lightweight

- lightweight steel

- material

- POSCO GIGA STEEL

- production

- safety

- sustainable

- sustainable car

- technology

- ultra high strength steel

- vehicle