Development of PosZET® GIGA Technology: Achieves Over Double the Welding Fatigue Strength at Half the Cost.

Publication in Prestigious Journal: Recognized for Academic and Economic Value by Global Scientific Journal Nature Communications.

POSCO’s research paper on high-performance, low-cost GigaSteel welding technology, PosZET® GIGA, was published in the prestigious scientific journal Nature Communications on February 12.

* Nature Communications, a comprehensive science journal published by the Nature Portfolio, is recognized for its authority in materials science, among others (Impact factor of 16.6).

Automobile manufacturing relies heavily on the welding of various steel materials, where not only the inherent characteristics of the steel but also the strength of the welds are crucial. The welding technology developed by POSCO is expected to enhance the applicability of POSCO’s ultra-high-strength steel plates, GigaSteel, in automotive materials.

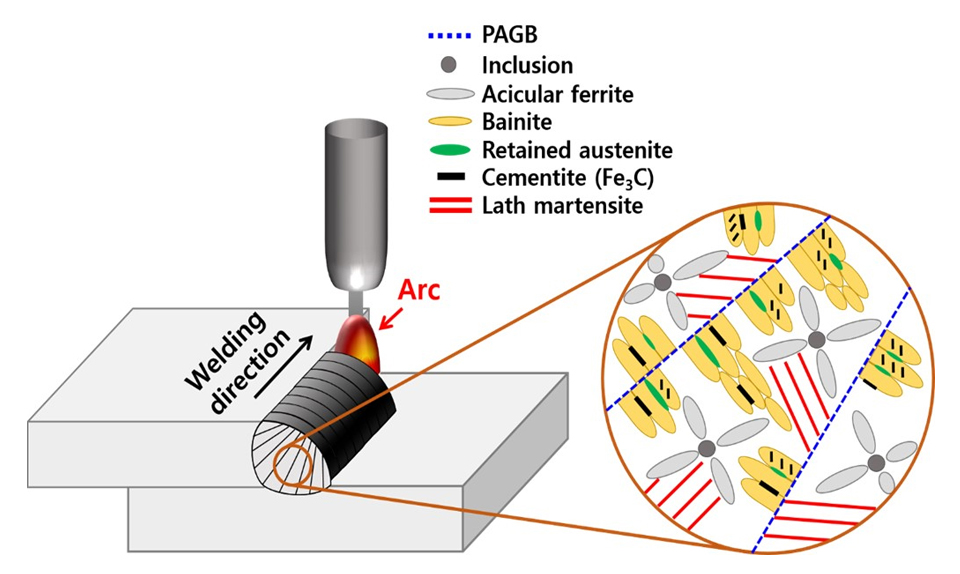

▲ The schematic diagram unveiled by the joint research team of POSCO and Changwon National University illustrates the formation mechanism of the fine microstructure in GigaSteel weld metal.

POSCO’s GigaSteel, boasting tensile strengths above 980 MPa, has traditionally utilized a substantial addition of nickel (Ni) for welding materials. PosZET® GIGA introduces a technology that replaces nickel with an optimal blend of niobium (Nb) and chromium (Cr) for the welding material (wire), creating a complex and dense network-like microstructure in the weld metal*, enhancing both strength and toughness simultaneously.

* Weld Metal: A portion of the weld area where the base metal and the welding material (wire) melt together during welding and solidify.

Utilizing PosZET® GIGA increases the bending fatigue strength of the joint by more than double compared to conventional methods and impacts toughness by approximately 15%. Applying this technology to manufacturing automotive parts such as chassis and frames can improve vehicle safety, as joints are less likely to break under repetitive impacts or temperature changes than when traditional welding techniques are applied. Additionally, as the enhanced performance of the welds allows for a reduction in steel plate thickness, vehicle lightweight designs can be accomplished. This new method costs about half that of the conventional approach, which primarily uses nickel.

In joint research with Changwon National University, POSCO has scientifically elucidated this technology for the first time globally. The study revealed the atomic-level impact of adding niobium and chromium on the microstructure of the weld metal. This research, acknowledged for its academic significance and commercial viability, has been published in the globally renowned journal Nature Communications.

PosZET® GIGA has recently received technical application approval from global automotive companies and is slated for use in actual automobile parts. POSCO plans to continue expanding the sales of GigaSteel utilizing this technology.