Uncover the steelmaking process at POSCO’s Gwangyang and Pohang Works

Pictured here: Scene from one of POSCO’s steel plants

Steel is one of the most common and useful metals. But do you know how it is actually made? Let’s go behind the scenes of one of the world’s leading steelmakers, POSCO, to discover the process of how steel is made.

Pictured here: Gwangyang Works is a world leading works with optimal layout to specialize in the production of automotive steel

The 3 Step Steelmaking Processes

For easier understanding, steel is made through 3 different stages which are ironmaking, steelmaking and rolling (continuous casting processes).

1) Ironmaking: a process of smelting iron ores into hot metal.

Iron ore and coal are gathered from all around the world and unloaded onto the raw materials dock.

Pictured here: Dock where iron ore and coal are gathered

For proper heat transfusion in the blast furnace, iron and coal must be solidified from their powder form. The process of solidifying iron and coal is called sintering and coking, respectively. The pretreated iron and coal are stacked into layers in a 100m tall blast furnace. Then hot air at 1,200 degrees Celsius is blown into the furnace, causing the coal to burn which melts iron ore into molten iron.

Pictured here: 100m tall blast furnace where iron ore melts into molten iron

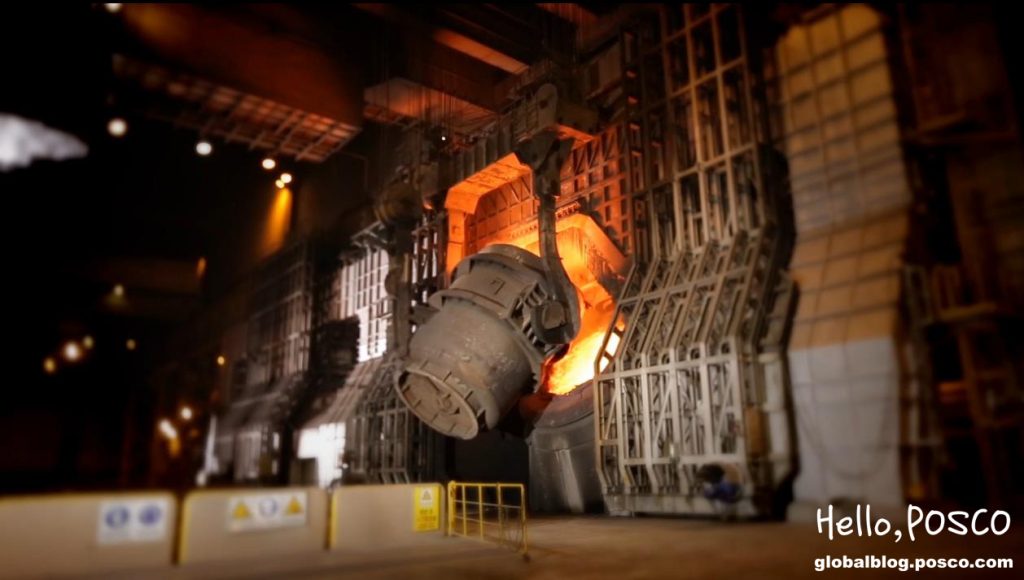

2) Steelmaking: a process of removing impurities from hot metal to create crude steel.

The molten iron created in the blast furnace contains various impurities that diminish its strength and durability once it is hardened into steel. The molten iron from the blast furnace is transported into a torpedo car and poured into a converter furnace.

Pictured here: The molten iron from the blast furnace is transported into a torpedo car to be taken to a converter furnace

In the converter furnace, pure oxygen is added to burn off substances such as carbon, phosphorous and sulfur to create purified molten steel. At this point, the temperature and substance composition is precisely adjusted to customer’s various demands.

Pictured here: Molten iron being poured into a converter furnace to be purified

Pouring the molten steel into molds and cooling into solid creates a semi-finished material called slabs which are used to make finished steel products.

Pictured here: Molten steel being created into slabs

Solid steel is categorized based on shape. Slabs are wide and flat. Blooms are rectangular bars and billets are thinner, square bars.

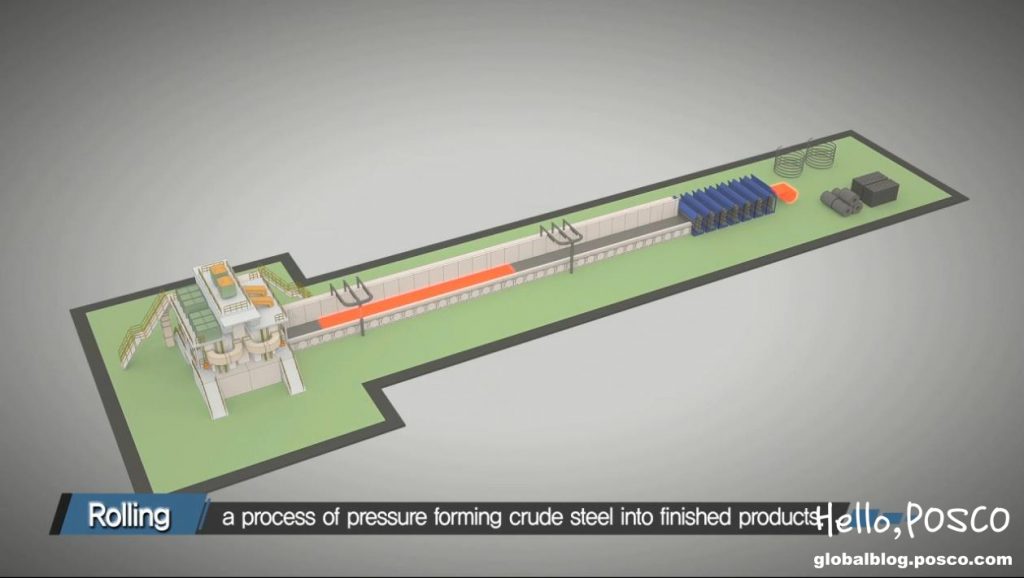

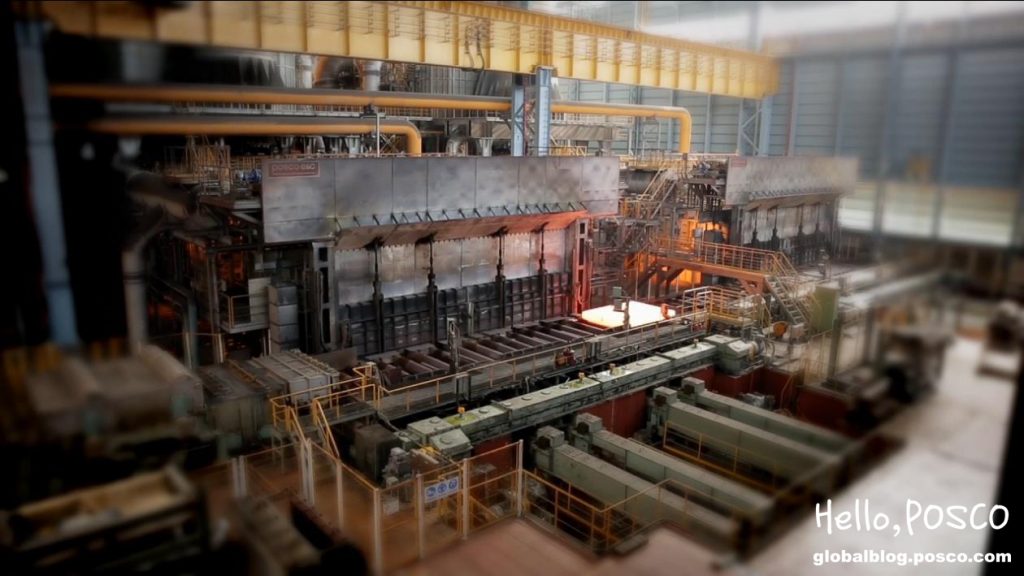

3) Rolling: a process of pressure forming crude steel into various finished products.

The final stage of the steelmaking process involves continuous casting where steel is forged into various steel products. Through the process of rolling, steel can be treated differently to be put to a variety of uses.

Pictured here: Slabs being passed between rollers to turn crude steel into finished products

What is steel used for?

POSCO steel products are used in every part of our daily lives ranging from buildings to smartphones to satellites in space.

The different types of products that can be created include:

1) Hot-rolled products

2) Cold-rolled products

3) Coated Steel

4) Electrical Steel Plates

5) Steel Plates

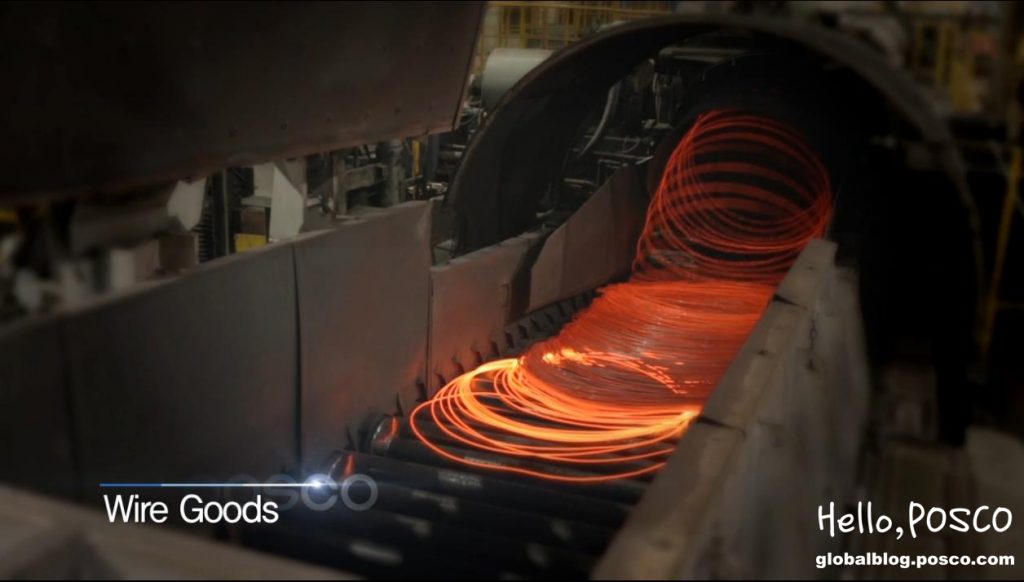

6) Wire Goods

7) Stainless Steel

Read on to find out more about the steel products around us.

Hot-rolled products are made from slabs passed through rollers above 1,100 degrees Celsius. These are used for construction materials and pipes in various industries.

Cold-rolled products which are created by making hot rolled products thinner at room temperature are used in general appliances, barrels and automobile frames.

Coated steel which is created by coating cold rolled products with zinc are used in high end appliances, office equipment and automobile exteriors.

Electrical steel plates are created by adding electrical properties are used in transformers and motors.

Steel plates which are thick and rectangular in shape are used in large structures such as buildings, vessels and oil pipelines.

Wired goods are created when billets are passed through a roll with a round hole and is used for automobile tire cords, wires for bridges, piano strings, underwater cables and more.

When nickel and chrome are added to steel it produces stainless steel which are used in kitchen appliances, medical equipment, exterior walls and roofs of buildings.

POSCO Ushers in Era of New, Eco-friendly Technologies

Pictured here: Pohang Works, the root and heart of the Korean steel industry.

POSCO was the first in the world to use a more economical and eco-friendly method of steelmaking compared to a blast furnace. The FINEX method uses iron ore and coal in its original form, skipping the coking and sintering processes.

Pohang Works is driving innovations in steel technology and leading in production of high quality products. It operates a state of the arts R&D center and production monitoring center that monitors production 24/7.

In addition, there is an Environmental Center that monitors emissions of pollutants in real time.

Click on the videos below to see the full steelmaking process at POSCO’s Gwangyang Works and Pohang Works, the root and heart of the Korean steel industry.

- automobile

- blast furnace

- carbon

- continuous casting

- crude steel

- Eco-friendly Technologies

- Electrical Steel Plates

- Environmental Center

- FINEX

- Gwangyang Works

- how is steel made? steelmaking process

- molten iron

- Pohang Works

- POSCO

- process of making steel

- production

- slabs

- stainless steel

- steel

- steel development

- steel production

- steel products

- steelworks

- Step Steelmaking Processes

- what is made of steel?

- what is steel used for

- Wire Goods