Winter conjures up images of fluffy snow piles high and frozen lakes. It also brings to mind a whole fleet of fun options ideal for the freezing cold – skating, sledding, skiing and more.

But to fully enjoy those winter sports, you need to have the right equipment for the season. Playing on the ice requires skates, while sliding down the snow-covered slopes requires skis – or even a bobsled or luge, for the serious winter sports enthusiast.

All these sports require steel. So let’s take a look at the role steel plays in bringing our favorite winter sports to life.

Slashing Across the Ice with Steel Skates

Whether it’s for ice hockey, figure skating or just a leisurely recreational skate, a pair of skates and a big sheet of ice is one of the most popular ways of having fun during the winter.

Actually, the oldest known skates are around 5,000 years old, and were made from the leg bones of large animals. But around the 14th century, people in the Netherlands started using iron runners, which were attached to people’s shoes with leather straps. Back then, people used poles to push themselves over the ice, but with the invention of double-edged blades around the year 1500, people gained the ability to push and glide directly with their skates. Finally, in the 19th century, steel began to be used for skates, giving them the strength needed for modern winter sports.

For today’s skates, typically the blades use tempered carbon steel that has been heat treated, and then covered in chrome – although some also use aluminum or stainless steel, and others even use titanium. The more high-end blades use better grades of steel than less expensive types. Because an important part of skating well is the blade’s edge, stronger grades of steel help hold the sharpness of the edge longer, so can go longer between sharpening.

Skate blades are thin – for hockey, usually just over 3 millimeters, while goalie and figure skater skates can be a bit wider. Surprisingly, though, the blades are not just a flat piece of metal. In fact, skate blades have a concave groove or “hollow” in them, so each blade actually touches the ice in two spots. This gives each blade an inside and outside edge, making them faster and more powerful.

Skis and Other Downhill Devices

Recently, we looked at how steel has proven pivotal for downhill fun as it is the main material in ski lifts. But in addition to helping people get up those big, snow-covered hills, steel also helps them come down again.

That’s because the serious downhill sports go seriously fast, and that means major stress on the equipment (and on the rider). Skis and snowboards typically have a thin strip of steel around the edge to strengthen the board and help carve the snow and ice better while turning.

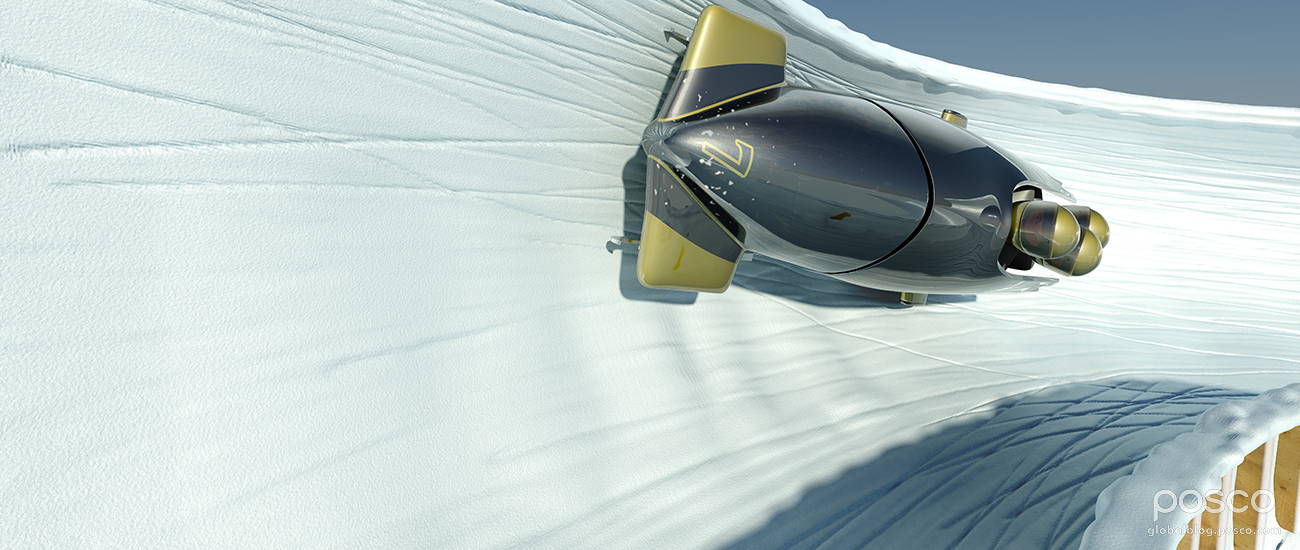

In bobsledding, teams used to have a lot more latitude for coming up with their own sleds, so they would experiment with different alloys for the blades. But since 2006, the bobsledding governing body announced a set of standards for the steel blades, so now everyone uses the same type of metal.

Luge and skeleton are two more high-speed sleds, but much smaller than the bobsled. Their frames are made of steel, and brakes are forbidden in the competitive models. Only on the luge do participants start sitting on the sled, whereas for the skeleton and bobsled they take a running start. For luge, they travel feet-first, while skeleton is head first. The luge also comes in one-person and two-person versions.

The sleds do vary a bit in their steel blades, though. Skeletons have tubular steel blades, which have a larger surface area and slow the sled a bit, whereas luge blades are sharped steel, for maximum speed. But for all these sports, steel blades form the connection between the rider and the ice, creating the foundation for their incredible speeds (lugers can reach 140 kilometers per hour).

Snow Machines

Sometimes to get through the deep snow – when you don’t have a big, steep slope handy – you need an engine to power you along. One of the most popular machines of winter, for those living in the great outdoors, is the snowmobile, which can be both practical and fun.

Of course, steel has long been an integral part of the internal combustion engine. In addition, snowmobiles rely on steel for a variety of other parts. The skis at the front of the snowmobile can be made from a variety of materials, including steel. Studs, which go through the track to create traction, are usually made from steel, too, providing strong, durable traction in the snow and ice.

There is also another steel machine that is as slow as the snowmobile is fast, but it is vital for skaters so they can enjoy an ice rink – the resurfacer (commonly known as a Zamboni). Weighing some 2,500 kilograms, a resurfacer needs to carry upwards of 380 liters of water, along with the blades and other equipment it uses to clean the ice and lay down a new coating of water. A resurfacer needs steel for the strength to support such a heavy machine plus the durability in cold conditions.

Winter is an exciting season with a whole range of special games and sports. And thanks to steel, there are even more fun things we can do.

Conquering Mountains with Steel