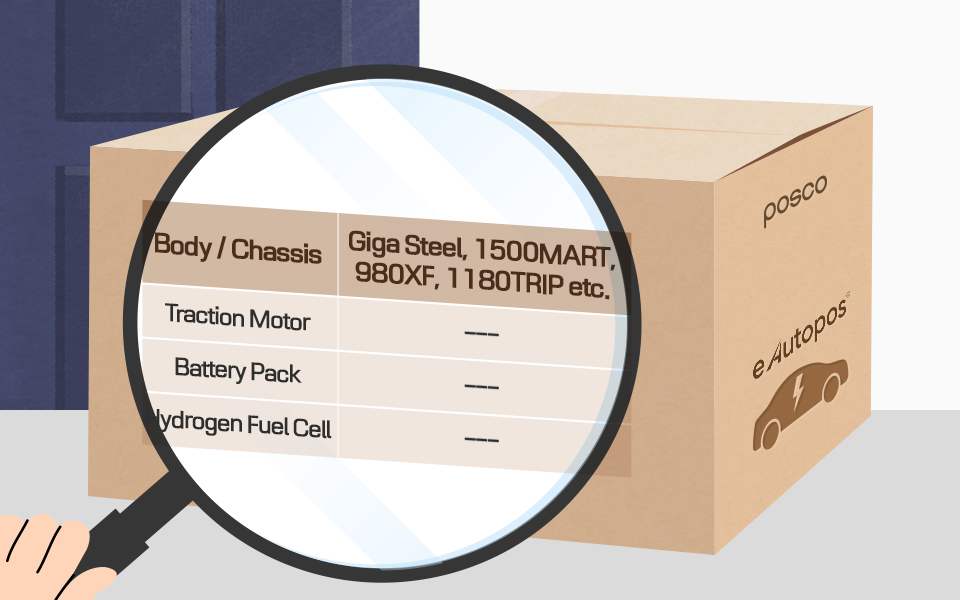

Ding~Dong! A parcel was left at the doorstep. It was a large box with an electric car drawn at the front, and it came with a card. Two words — POSCO and eAutopus — were written on the box, and the card read “e Autopos Unboxing”. Join us for the unboxing of POSCO’s integrated brand of sustainable automotive product & solution, “e Autopos”.

l Mission: Observing the Box

Before opening the box, let’s take a closer look from the outside. “e Autopos” written on the picture of an Electric Vehicle (EV) is POSCO’s integrated brand of eco-friendly automotive product solutions. The brand refers to POSCO’s steel and secondary battery material products used in EVs and Fuel Cell Electric Vehicles (FCEVs), and customized solution packages that can be applied to these products. e Autopos is a combination of the words eco-friendly and electrified AUTOmotive solution of POSco.

l Now for the Real Unboxing! eAutopus Car Body

The inside of the box reveals a car body that looks quite solid.

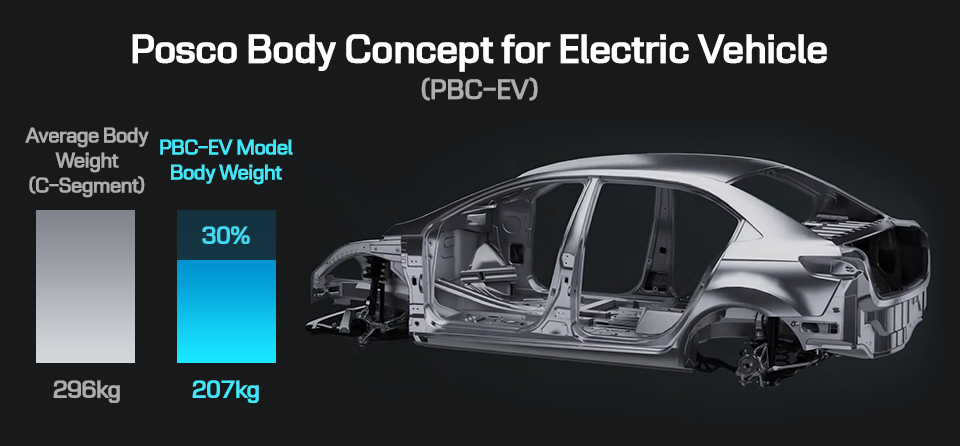

The car body consisting of eAutopos products is light and strong. To protect the environment, cars must be lighter because a heavier car needs more energy and emits more greenhouse gas. EVs are about 200kg heavier than conventional fuel engine vehicles because of the battery pack weight, so reducing weight is an essential task for EVs. However, making a car lighter isn’t as easy as it sounds. Developing a lightweight and strong body is important for the safety of the users because the vehicle body absorbs and distributes shocks in the event of an accident and also prevents battery damage.

Accordingly, POSCO developed PBC-EV (Posco Body Concept for Electric Vehicle), POSCO’s solution for EVs where Giga Steel is applied. Applying more than 45% of Giga Steel, PBC-EV achieved a weight reduction of about 30% compared to conventional fuel engine vehicles of the same size. Giga Steel is more than three times stronger than aluminum, which has recently been applied to automotive bodies and can withstand a weight of more than 100kg per 1mm2.

s▶See more about Giga Steel

• Can a ‘25-ton truck’ really hang on steel the size of a 10 won coin? For real?

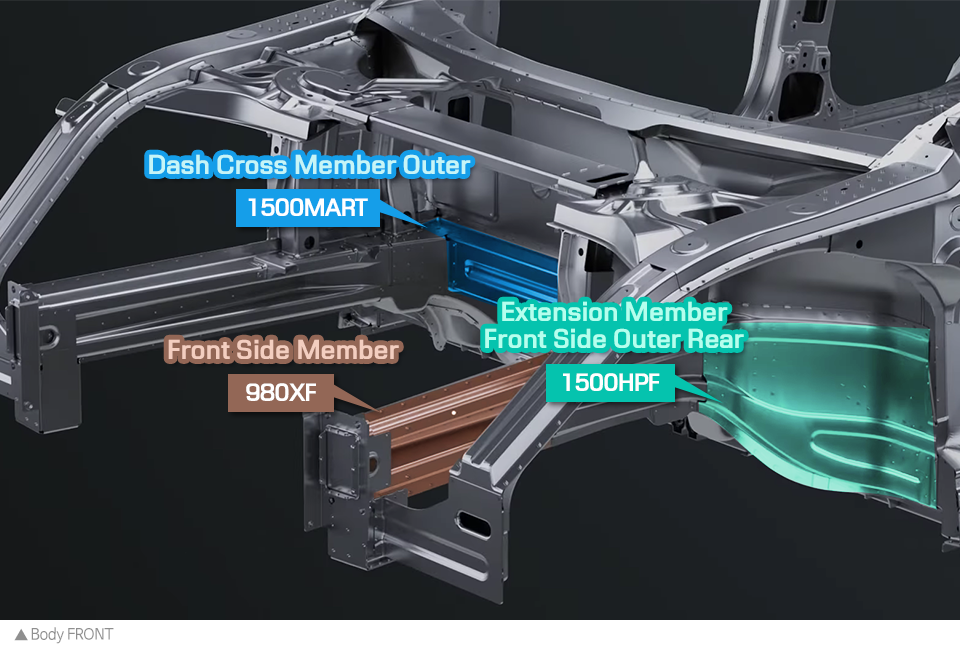

The e Autopos automotive body solution includes many of POSCO’s advanced steel grades because the passenger and battery spaces should be designed to prevent deformation in case of an accident or a collision. Also, the traction motor space in the front, the trunk space in the rear, and the side space should be designed to absorb the collision force.

980XF is applied for the Front Side Member that absorbs shock at the front of the vehicle due to its excellent tensile strength* and elongation**. For the Side Sill Inner Reinf, which absorbs shock at the relatively narrower side area, 1180 TRIP product is applied because of its outstanding strength and elongation.

In the event of a collision, the shock is first absorbed in the front, rear, and sides. The remaining energy is then transferred to the passenger and the battery space inside the vehicle. Therefore, it is important to apply a steel product that prevents this. The strength of the steel applied here should be higher than that of the ones used in the areas that receive the shock directly.

The remaining energy after the initial absorption in the Front Side Member is transferred to the Extension Member Front Side Outer Rear, and here comes another important task: this part must sustain the impact without any deformation. Accordingly, since the shape is relatively complicated, a 1.5 GPa-class 1500HPF product was applied to secure formability and collision resistance at the same time. 1500HPF is formed by heating steel plates at a high temperature of 900°C and then cooled down and shaped in a mold.

The Dash Cross Member Outer and Seat Cross Member, which serves to protect passengers by suppressing automotive deformation in the event of a collision, employs 1500MART. 1500MART is a high tensile strength product of 1500MPa and maximizes the prevention of automotive body deformation.

**Elongation: The rate at which steel can be stretched on both sides without breaking. The higher the elongation, the harder it is to break, so the shock is absorbed through deformation.

l Eco-friendly Car Chassis Made Complete with eAutopus

▲ The Chassis of an EV

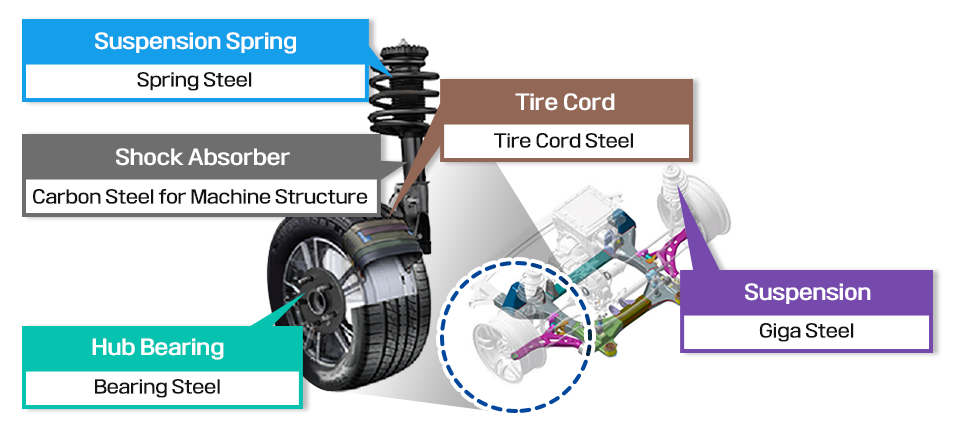

Now let’s take a closer look at the “chassis” which is in charge of driving functions! Connected to the bottom of the car body, the role of the chassis is to enable driving and absorb shock. The chassis is composed of Suspension and Hub Bearing, the essential machine parts required to run a vehicle, and Suspension Spring and Shock Absorber to absorb the shock from the road.

The Giga Steel introduced in the e Autopos automotive body solution is also applied to the suspension. POSCO developed a lighter, longer-lasting suspension with Giga Steel. POSCO Bearing Steel is used for hub bearings that are mounted on automotive wheels to help the wheels rotate. Since POSCO Bearing Steel is used for wheels that are directly connected to passenger safety, its quality is strictly managed and it features high resistance to abrasion, cracking, and deformation.

Tires with e Autopos solution are strong to puncture. This is possible because of POSCO Tire Cord Steel! The Tire Cord Steel supports the weight of the vehicle, maintains the shape of the tire, and extends the life of the tire. POSCO’s Tire Cord Steel is made of high-strength carbon, has excellent machinability and high strength, so it is lightweight and features excellent driving stability.

POSCO’s Spring Steel is applied to the Suspension Spring, which is responsible to secure comfortable rides by minimizing the shock or vibration transmitted from the road. As for the Shock Absorber, POSCO’s Carbon Steel for Machine Structure is adopted. POSCO Spring Steel is stronger than conventional spring steel by more than 200 MPa, yet 15% lighter since the number of coils wound around is minimized, making it suitable for weight reduction. As such, e Autopos solution is applied to all parts of the eco-friendly automotive chassis!