Among the tightening global environmental regulations aimed at tackling the climate crisis, the decarbonization of the steel industry is emerging as a critical task for building a sustainable future. POSCO Group is leading a new paradigm in the steel industry through its differentiated decarbonization strategy, which includes HyREX technology, carbon-reduction bridge technologies, and a transition to clean energy. This special feature takes a closer look at POSCO Group’s “2050 Decarbonization Roadmap” and its phased technology deployment strategies that will drive innovation in steel decarbonization.

Towards a Sustainable Future! POSCO Group is Leading the Decarbonization Transition in the Steel Industry

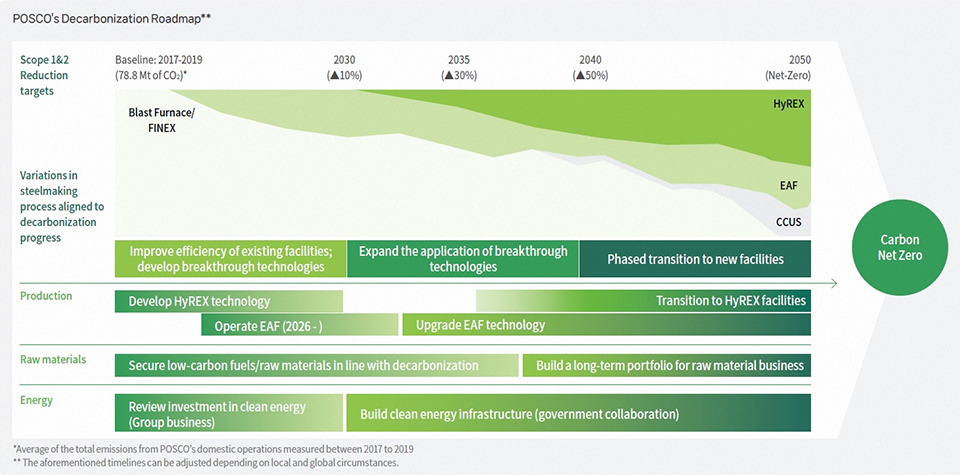

POSCO Group has established its “2050 Decarbonization Roadmap,” which lays out a comprehensive strategy to decarbonize its steel business, the group’s most carbon-intensive sector. The roadmap covers critical areas such as raw materials, investment, energy, and technological innovation. POSCO Group keeps driving its decarbonization journey forward through continuous monitoring and annual updates.

▲POSCO’s “2050 Decarbonization Roadmap,” which includes a comprehensive mid- to long-term strategy encompassing technology development, facility investment, raw material procurement, and energy procurement. [From the 2024 POSCO Holdings Sustainability Report]

Development of Carbon Reduction Bridge Technologies

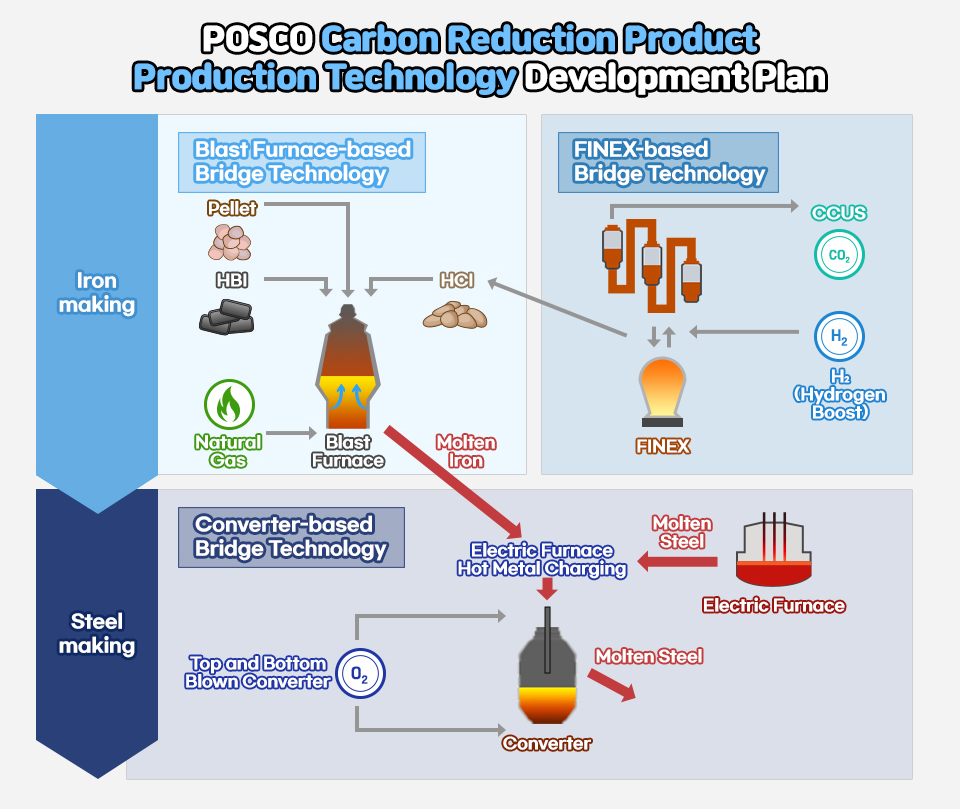

During the transition to hydrogen reduction ironmaking, POSCO Group is striving to reduce carbon emissions through the parallel deployment of multiple bridge technologies, including the use of low-carbon fuels and raw materials, the introduction of large-scale EAFs, and CCUS demonstration projects. With intelligent factories powered by data and AI, POSCO Group is improving energy efficiency and ensuring a safer working environment.

① Blast Furnace-Based Carbon Reduction Technologies

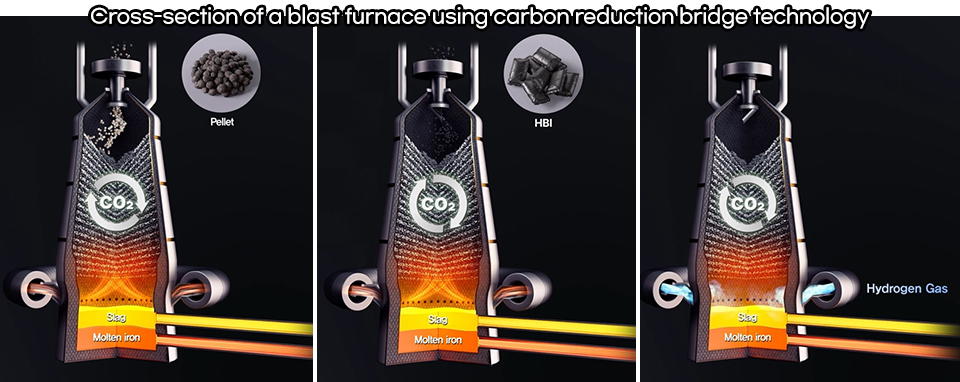

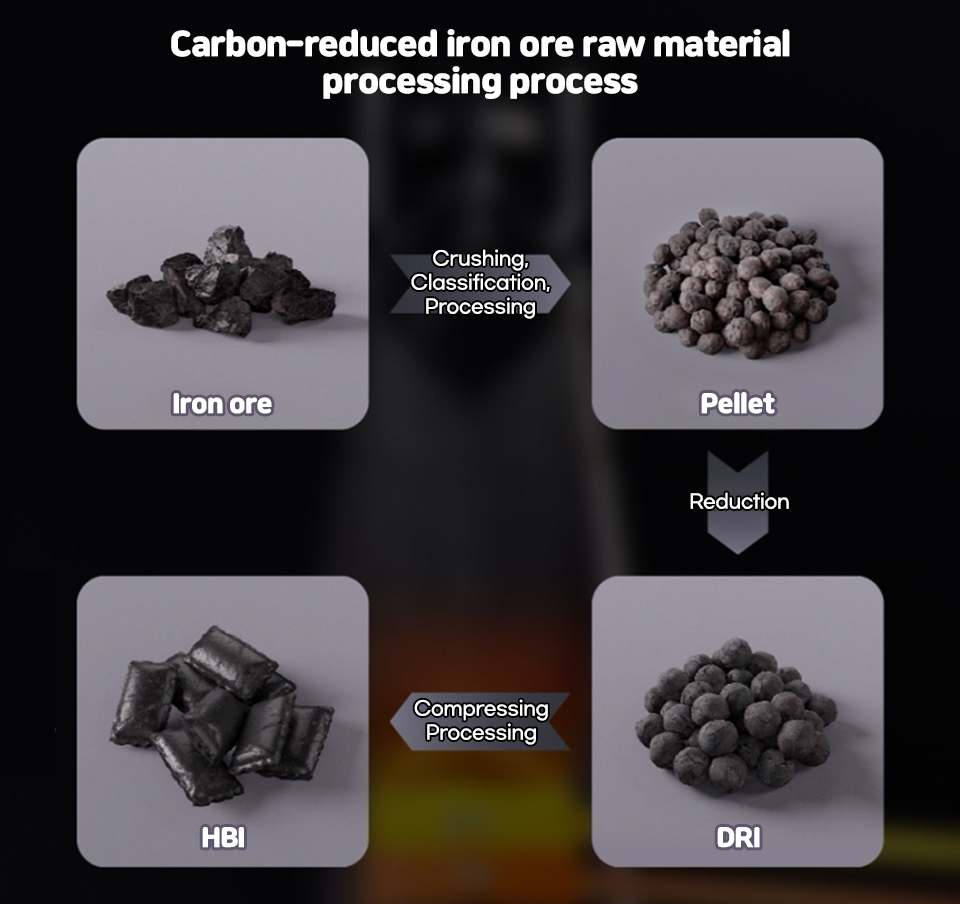

The blast furnace, commonly referred to as a smelting furnace, serves as a core facility in steel production. Coal (coke) and iron ore (sintered ore) are fed into the top of the furnace and layered, while hot air is injected from the bottom, melting the raw materials to produce molten iron. To reduce carbon emissions from blast furnaces, improving the raw materials and reduction processes is essential. POSCO Group is advancing blast furnace-based carbon reduction technologies through three main methods: pellets, Hot Briquetted Iron (HBI), and hydrogen-rich gas.

Pellets are made by crushing and screening iron ore and shaping it into uniform spherical forms. These are used in blast furnaces as a substitute for sintered ore, which was traditionally used as ironmaking feed. Simply switching raw materials from sintered ore to pellets can reduce the amount of fossil fuels required in sintered ore production, thereby lowering the CO2 emissions intensity. In addition, pellets melt and are reduced more effectively at higher temperatures than sintered ore, which helps decrease coal consumption in the blast furnace.

Hot Briquetted Iron (HBI) is produced by removing oxygen from iron ore to make Direct Reduced Iron (DRI) and then compressing it into pillow-shaped briquettes, which are charged into the blast furnace. This method significantly reduces the amount of coal required for the reduction process. Assuming 100 kg of HBI are used to produce one ton of molten metal, approximately 100 kg of CO2 emissions can be avoided.

Hydrogen-containing gas method uses natural gas (NG), a low-carbon fuel, as a reducing agent instead of coal. The main component of natural gas, methane, is reformed into carbon monoxide and hydrogen during the reforming process, generating hydrogen-containing gas. This gas is then injected into the tuyere at the bottom of the blast furnace and used as a reducing agent, which helps reduce coal consumption. In the first half of 2023, POSCO installed a natural gas injection system for its blast furnaces and confirmed its carbon reduction effect. The company is also working with 29 industry–academia–research partners on the national R&D project COOLSTAR.* Based on this facility, POSCO is developing hydrogen injection technology for blast furnaces and plans to package it as a bridge technology to establish a low-carbon blast furnace model.

**COOLSTAR (CO2 Low emission technology of Steelmaking And hydrogen Reduction): A national R&D project led by the Ministry of Trade, Industry and Energy of Korea to develop hybrid steelmaking technologies that reduce CO2 emissions.

② BOF-Based low Hot Metal Ratio (HMR) Operation Technology

The basic oxygen furnace (BOF) is a facility that produces refined steel (ingot steel) by blowing oxygen into molten iron (molten metal) from the blast furnace to remove impurities and adjust the temperature and composition. Since more than 80% of the CO2 emissions generated in the production of one ton of ingot steel occur during the molten iron production stage, reducing the amount of molten iron used in the BOF is critical for cutting carbon emissions. POSCO Group is developing low Hot Metal Ratio (HMR) operation technology to lower the proportion of molten iron charged into the BOF. Let’s take a look at two representative technologies used in low-HMR operations.

The Melted Scrap Charging Method reduces the amount of molten iron used in the converter by blending molten iron from the blast furnace with ingot steel produced in the EAF. Since the EAF uses recycled steel scrap as raw material, its carbon emissions are significantly lower than those of the blast furnace. Therefore, by utilizing scrap melting and charging technology in the EAF, producing 2.5 million tons of molten metal annually is expected to achieve carbon reductions of up to 3.5 million tons compared to conventional blast furnace operations. However, because of the residual elements in scrap, there are limitations in manufacturing high-grade steel products. To address this, POSCO Group is developing a technology that combines blast furnace molten iron with EAF molten metal to simultaneously achieve carbon reduction and the production of high grade steel.

The Oxygen Top & Bottom Blown (OTBB) Converter Technology increases the amount of steel scrap charged into the BOF by injecting oxygen from both the top and bottom to secure additional heat sources. In BOF, no external heat is supplied; the heat required for steelmaking is generated by the oxidation of impurities in the molten iron. Therefore, reducing the amount of molten iron and increasing the scrap ratio can lead to a drop in molten iron temperature. By injecting oxygen not only from the top but also from the bottom, the Oxygen Top & Bottom Blown (OTBB) Converter Technology enhances secondary combustion and maximizes heat transfer efficiency, effectively overcoming this limitation.

In this way, POSCO Group has developed technologies to increase scrap utilization by leveraging its existing BOF facilities. By optimizing scrap charging practices and adopting a two-stage BOF process, the company has expanded the scrap ratio to over 30%. In addition, when applying POSCO Group’s proprietary FINEX molten iron in low Hot Metal Ratio (HMR) operation technology, the molten iron ratio (HMR) in the BOF can be lowered to below 70%, which is expected to significantly reduce greenhouse gas emissions in the ironmaking process. Through these measures, POSCO plans to respond in the short term to growing customer demand for low-carbon steel products before fully transitioning to decarbonized production facilities.

EAF-Based Low-Carbon Steel Production Technology

Building an EAF production system to respond to EU CBAM and customer demand for carbon reduction

To accelerate global decarbonization, prevent carbon leakage, and protect the competitiveness of its domestic industries, the EU plans to fully implement the Carbon Border Adjustment Mechanism (CBAM) starting in 2026. CBAM is a system that imposes additional costs (carbon taxes) on products imported into the EU based on the amount of carbon emissions generated during their production processes. In response to this international regulatory shift and increasing customer demand for carbon reduction, POSCO Group established a dedicated CBAM response team in August 2022. The company is actively collaborating with POSCO Europe and POSCO International to strengthen its response to CBAM.

▲To transition to a carbon-reducing production system, POSCO invested approximately 600 billion won in February of last year to begin construction on a large-scale electric furnace plant within its Gwangyang works with an annual capacity of 2.5 million tons. Full-scale operation is scheduled for 2026. The photo shows a panoramic view of the Gwangyang works.

In addition, to establish a low-carbon production system, POSCO Group began construction of an EAF plant capable of reducing CO2 emissions by up to 75% compared to conventional blast furnaces, with an annual capacity of 2.5 million tons at Gwangyang Works in February 2024. The facility is targeted to commence operation in 2026. By applying Melted Scrap Charging Method, the plant is also expected to enable the production of high grade steel, which was previously difficult to achieve with traditional EAF operations. Through this initiative, POSCO aims not only to actively respond to CBAM but also to ensure a stable supply of low-carbon steel products.

Development of Carbon Capture, Utilization and Storage (CCUS) Technologies

▲An exhibition model showing POSCO Group’s carbon capture, utilization, and storage (CCUS) technology process.

POSCO and the POSCO Holdings Future Technology Research Laboratories are developing a wide range of CCUS* technologies to capture and recycle CO2 emitted from steelworks, thereby reducing overall carbon emissions. Currently, CCUS technologies are being demonstrated through multiple approaches, among which three representative applications stand out.

*Carbon Capture, Utilization and Storage (CCUS): A technology that captures large volumes of CO2 emissions and either utilizes them directly for industrial purposes, converts them into higher-value products, or stores them permanently or semi-permanently.

CO2 Injection and Conversion Technology in Coke Ovens

The first approach involves separating and capturing CO2 generated from the steelmaking process and injecting it into coke ovens, where it serves as a heat source for by-product gas power generation. Since 2021, POSCO has been collaborating with Research Institute of Industrial Science & Technology (RIST) on a joint public–private national R&D project to demonstrate CO2 capture and conversion technologies. A demonstration test conducted at Pohang Works in January 2024 confirmed that high-purity refined energy is not required, and that medium-purity CO2 can be effectively injected into coke ovens.

The demonstration also showed an increase in the calorific value of by-product gas (COG, Coke Oven Gas) generated from the coke ovens. COG is used as an energy source for fuel gas, by-product hydrogen production, and high value-added chemical products, and higher calorific value directly enhances its utility. Recognizing these achievements, this coke oven CO2 injection and conversion technology was selected as one of the MOTIE’s Top 10 R&D Technologies, and received the Minister’s Award.

Development of Mineral Carbonation Technology

The second approach is to apply mineral carbonation technology. The POSCO Holdings Future Technology Research Laboratories is developing CCU technology that mineralizes captured CO2 for onshore storage or reuses it as construction material.

▲Participants pose for a commemorative photo at the launch meeting for the ‘Pilot Project for Land-based Carbon Dioxide Storage in Abandoned Mining Sites’ in August 2024.

In July 2024, POSCO Holdings was selected as the lead organization for the national pilot project “Onshore Storage of CO2 Using Abandoned Mine Shafts,” organized by the Ministry of Trade, Industry and Energy (MOTIE). This project is designed to react CO2 emitted from steelworks with steel slag to immobilize the carbon and produce carbonated slag at a scale of 300 tons, which is then backfilled into abandoned mine shafts. In November 2023, POSCO Holdings began operating a demonstration plant in collaboration with Samcheok. Based on this pilot project, POSCO Holdings aims to address the carbon storage shortage, a critical limitation of national CCS initiatives, and contribute to the decarbonization of the steel industry.

Phased Commercialization of CCS

The third approach is to gradually apply CCS technology. POSCO has been exploring the most suitable carbon capture technologies for various facilities including coke ovens, sinter plants, hot blast stoves and power plants by leveraging commercially available CO2 capture solutions. Based on these assessments, POSCO plans to gradually expand CO2 capture starting with the most efficient and effective facilities.

After being compressed, liquefied and purified, the captured CO2 gains the physical properties needed for transportation and storage. The processed CO2 is injected into saline aquifers or depleted oil and gas fields that have sealed geological structures, where it is stored permanently. The sealed geological structure means a formation where non-permeable rock layers overlie permeable sedimentary layers, blocking the gas and keeping it from escaping.

POSCO Group is exploring promising CO2 storage sites not only at the Donghae Gas Field but also in Southeast Asia, including Indonesia, and in northwestern Australia. In 2024, POSCO Group was selected for a program by the Export-Import Bank of Korea that supports feasibility studies for international emission reduction projects. Through this program, the company carried out a preliminary CCS feasibility study at PT. Krakatau POSCO in Indonesia. Based on the findings, the company plans to further develop its CCS application methods and gradually expand their use to domestic steel mills.

POSCO’s Hydrogen Reduction Ironmaking (HyREX) Technology

▲POSCO’s HyREX hydrogen reduction ironmaking technology, displayed as a model at the 2024 Climate Industry International Expo.

POSCO is Securing a Low-Carbon Iron Ore Supply Chain through Fluidized Bed Reduction Furnaces

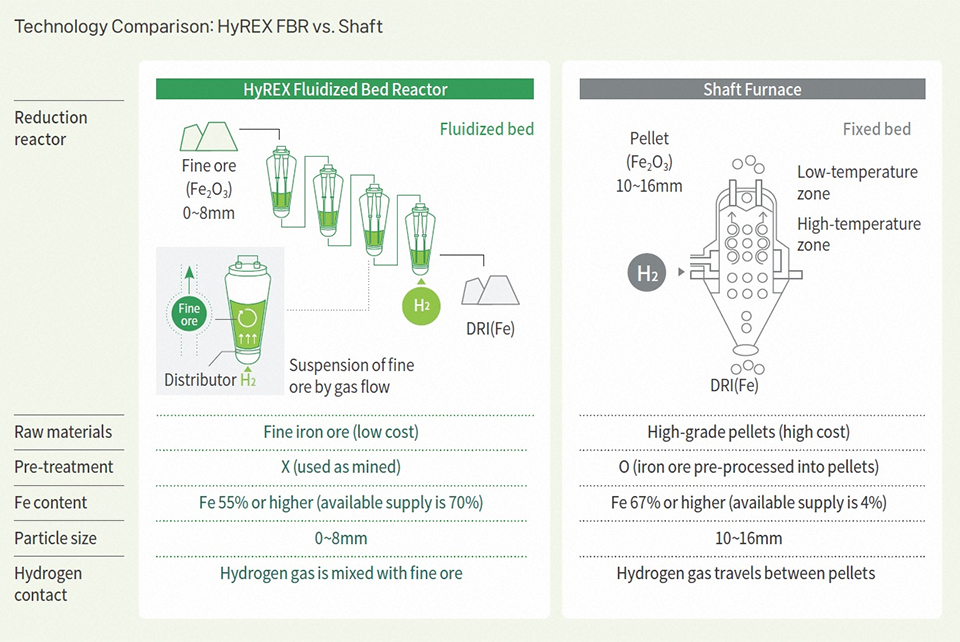

Hydrogen reduction ironmaking is a process that reduces greenhouse gas emissions in the ironmaking process by replacing the reducing agent and coking coal traditionally used to remove oxygen from iron ore with hydrogen. POSCO is developing hydrogen reduction ironmaking based on the fluidized bed reduction furnace technology of its already commercialized FINEX process. Unlike the shaft furnace method commonly used by overseas steelmakers, the fluidized bed reduction furnace has distinct differences in terms of raw material and equipment technology. Shaft furnaces require high-grade DR-grade pellets processed into uniform spherical shapes as raw materials, whereas fluidized bed reduction furnaces can directly utilize ordinary iron ore fines from mines without any additional processing, offering a clear cost and operational advantage.

Of the world’s total iron ore supply of 1.7 billion tons, DR-grade pellets account for only about 4%. This limited supply makes it difficult to meet global steel demand. If hydrogen reduction ironmaking is fully commercialized, competition for pellets is expected to intensify among overseas steelmakers that use shaft furnace technology.

In this increasingly competitive environment, POSCO Group has a strong advantage: by adopting the fluidized bed reduction furnace method, it can use iron ore fines directly from the mine without additional processing, which keeps production costs relatively low and improves raw-material security. In terms of equipment technology, the fluidized bed reduction furnace also allows easier temperature control than shaft furnaces. POSCO’s fluidized bed reduction furnace-based FINEX process, which incorporates hydrogen injection and direct reduced iron (DRI) production technology, is regarded as the most competitive technology in hydrogen reduction ironmaking.

Pushing for HyREX Commercialization by 2030

In 2021, POSCO Group initiated the permitting process to prepare 1.35 million square meters of land at its Pohang Works for the construction of a hydrogen reduction ironmaking plant. In July 2022, POSCO signed an engineering collaboration agreement with Primetals Technologies, a company with extensive experience in FINEX plant design. Based on this agreement, the two companies are jointly designing the main facilities of the HyREX demonstration plant and plan to construct a pilot facility with an annual capacity of 300,000 tons at Pohang Works.

POSCO Group aims to develop and complete the commercialization technology for HyREX through a demonstration project by 2030. Once national infrastructure, policy and institutional frameworks are in place, and market acceptance is secured, the company plans to gradually convert its existing blast furnace facilities to HyREX facilities.

Strengthening Global and Domestic Cooperation Networks for Hydrogen Reduction Ironmaking Development

Hydrogen reduction ironmaking has been recognized for its strategic importance to national security and the national economy. In January 2024, it was designated as a national strategic technology in Korea. In May 2024, “Development of Optimized Iron Ore Technology for Korean-type Hydrogen Reduction Ironmaking” (Steel Sector) was selected as one of the Global R&D Flagship Projects by the Ministry of Science and ICT. Building on this strong domestic consensus, POSCO Group is preparing a Korean-type hydrogen reduction ironmaking demonstration project in conjunction with government R&D programs, with a target of achieving commercialization by 2030. The company is also actively participating in various international technology development collaborations to accelerate global decarbonization in the steel industry.

Since 2023, POSCO Group has been operating the HyREX R&D Partnership to accelerate the development of carbon-reduction technologies by moving beyond competition to collaboration with global steelmakers. A total of 19 related companies—including global steelmakers, raw-material suppliers, and energy firms—are participating in this partnership. The first conference was successfully held in November 2024. POSCO has also been collaborating with the World Steel Association (WSA) and Swedish steelmaker SSAB. In 2021 and 2022, the company led the Hydrogen Iron & Steel Making Forum (HyIS Forum), and since 2023, the initiative has been expanded into the Breakthrough Technology Conference, which is organized by the WSA.

▲Content embodying POSCO Group’s decarbonization vision is on display at the 2025 Climate Industry International Expo. POSCO Group is pursuing substantial carbon reduction and expanded clean energy transition through AI and bridge technologies, centering on Korea’s Hydrogen Reduction Iron and Steel (HyREX).

Encompassing hydrogen reduction ironmaking, carbon-reduction bridge technologies, and energy transition, POSCO Group’s diverse real options strategies are expected to play a key role in accelerating the steel industry’s journey toward decarbonization. POSCO Group will continue to advance its decarbonization efforts in the steel industry, driven by technological innovation and a clear strategic roadmap. Follow POSCO Group’s decarbonization journey toward a more sustainable future!