POSCO celebrates the 50th anniversary of the completion of the first phase of the Pohang works. POSCO, which has played a role in driving the renaissance of the Korean manufacturing industry for the past 50 years, has set out to develop hydrogen reduction Ironmaking technology, which will be a game changer in the steel industry, with the goal of achieving carbon neutrality by 2050. Let’s take a look at the history and future of POSCO, which will start a new paradigm for iron from coal to hydrogen and create another legacy for the future.

[POSCO’s past]

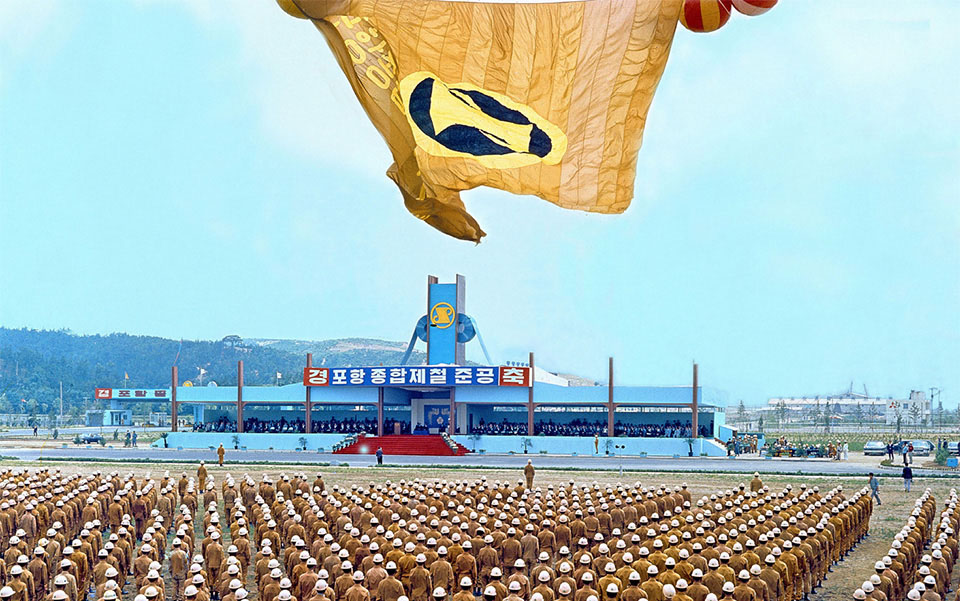

The first integrated steel mill(ISM), a long-cherished desire of Korea, was born in 1973.

On July 3, 1973, Korea’s first ISM was born with the completion of the first phase of the Pohang works. The five government-led ISM construction projects had been tried since 1958, but had failed each time. After many twists and turns, the project succeeded by using funds of the claims against Japan.

In 1973, President Park Chung-hee presented a specific vision for Korea’s economic development. In his State of the Union Address, he declared a plan for heavy and chemical industrialization, thus emphasizing the importance of the Pohang works, which was nearing completion at that time. President Park’s declaration, which focused on intensively nurturing six strategic businesses – steel, petrochemicals, machinery, shipbuilding, automobiles, and electronics – was rooted in the smooth completion of the first phase of the Pohang works.

Full government-wide support and passionate interest

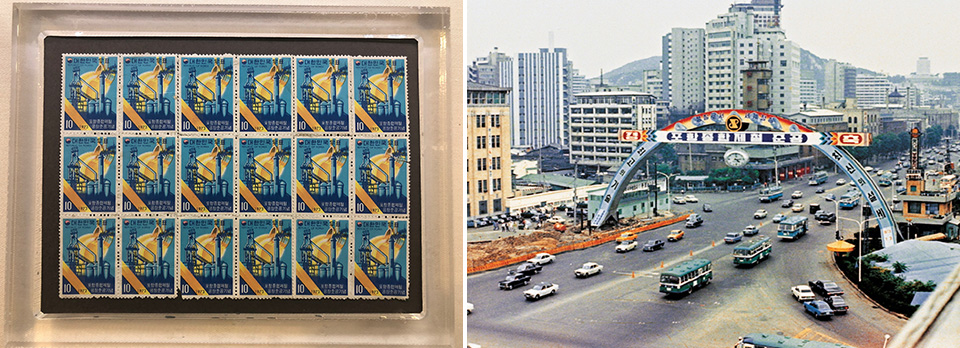

▲Commemorative stamps for the completion of the first phase of the Pohang works (left) and a large arch installation on Gwanghwamun Street in Seoul to mark the completion

The completion of the first phase of the Pohang works, which was a milestone that moved the wheels of Korean history and a turning point in the nation’s economic development, was possible thanks to the government’s full-scale support and the dedication of outstanding talents. It was a big, unprecedented project, and the amount was three times that invested to build the Gyeongbu Expressway.

During the 39-month construction period for the first phase of the Pohang works required 3,154,884 man-days in all, and 99,918 supervisors for technical guidance. In addition, a total of KRW 120.4 billion was invested in the project; KRW 49.3 billion of domestic capital and KRW 71.1 billion (USD 178 million) of foreign capital. The massive amount of resources and manpower invested in this project reflects the national attention and hot spotlight at the time.

▲First product shipped from Pohang works

The first phase of the Pohang works was a sign of success for the domestic steel industry. It achieved normal operation just four months after the completion. By July 1974, on the first anniversary of its operation, it had achieved a remarkable performance, resulting in a trade surplus of KRW 24.2 billion. POSCO also improved the quality of its products to an international level. For steel plates, it acquired international quality certification from Lloyd’s Register in the UK and other authoritative bodies in major countries. In 1973, its export performance reached USD 20 million in 21 countries.

POSCO’s steel products are the lever of the Korean manufacturing industry’s leap forward

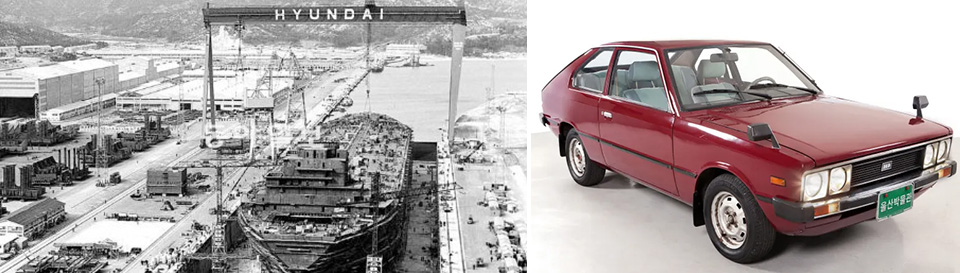

As POSCO grew and steel production increased, major domestic manufacturing companies also grew. This was because POSCO served as leverage in the manufacturing industry by producing high-quality steel domestically and supplying it stably at low prices. In June 1974, HD Hyundai Heavy Industries launched Korea’s first large oil tanker, Atlantic Barron, made with POSCO’s steel plates, and Hyundai Motor also developed the nation’s first vehicle model, the Pony, in the same year.

▲Atlantic Barron, the first large oil tanker launched by Hyundai Heavy Industries (left) and the Pony, Hyundai’s first car model (right), made with POSCO steel plates <※ Source: The Dong-a Ilbo (provided by Hyundai Heavy Industries), The Kyunghyang Shinmun (provided by Ulsan Museum)>

According to the Ministry of Trade, Industry and Energy, when the first molten metal flowed from the Pohang works in 1973, the domestic shipbuilding volume was 12,000 Compensated Gross Tonnage (CGT) and automobile production volume was only 25,000 units. However, POSCO’s steel production volume last year was 38.64 million tons (domestic), and the manufacturing industries using steel also showed rapid growth: the shipbuilding volume was 7.81 million CGT, and automobile production was 3,757,065 units.

[POSCO’s present and future]

Steel legacies created by POSCO, becoming stronger to overcome crises

As of 2023, POSCO has eight blast furnaces (three at Pohang works and five at Gwangyang Steelworks) and two FINEX units. The production of molten metal did not decrease even after the first blast furnace was retired because the capacity was increased according to the number of blast furnaces. In 2021, POSCO achieved a record-breaking performance, surpassing KRW 70 trillion in sales and KRW 9 trillion in operating profit for the first time since its foundation. Crude steel production was 45.33 million tons, with consolidated sales of KRW 76.3323 trillion and operating profit of KRW 9,238.1 billion.

According to the Ministry of Trade, Industry and Energy, when the first molten metal flowed from the Pohang works in 1973, the domestic shipbuilding volume was 12,000 Compensated Gross Tonnage (CGT) and automobile production volume was only 25,000 units. However, POSCO’s steel production volume last year was 38.64 million tons (domestic), and the manufacturing industries using steel also showed rapid growth: the shipbuilding volume was 7.81 million CGT, and automobile production was 3,757,065 units.

▲The first product is being produced at the second hot rolling mill in Pohang, which was restarted after being shut down for 100 days due to flooding.

In September 2022, Typhoon Hinnamnor caused flooding of a river near the Pohang works that flooded the factory areas, which are three times the size of Yeouido. However, despite expert predictions that plant restoration would take at least six months, POSCO demonstrated remarkable resilience by resuming normal operations at all of its factories on January 19, just 135 days later. Undoubtedly, this was made possible by the dedicated and competent employees who lead POSCO, a company that remains strong even in the midst of a crisis.

Creation of another legacy: carbon neutrality

POSCO is now preparing for another 50 years. POSCO has already achieved its first legacy by growing into the world’s most influential steelmaker (ranking No. 1 for 13 years in a row), starting with completion of ISM 50 years ago. Now, as the next step, it aims to create the second legacy by developing hydrogen reduction Ironmaking technology that does not require coal, with the goal of achieving carbon neutrality by 2050.

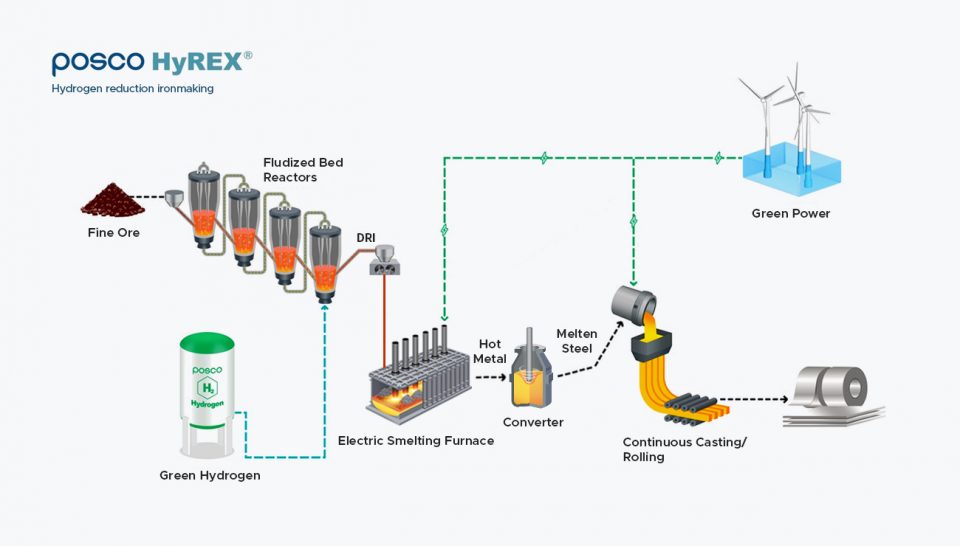

▲POSCO HyREX(hydrogen reduction ironmaking) concept.

POSCO aims to complete the hydrogen reduction Ironmaking system by gradually converting existing production methods such as blast furnaces. Now, POSCO is developing commercial hydrogen reduction Ironmaking technology. This development leverages POSCO’s proprietary HyREX (hydrogen reduction) technology, which itself is based on the company’s exclusive FINEX technology using fluidized reduction furnaces.

In July last year, POSCO signed a business agreement for cooperation in hydrogen reduction Ironmaking engineering technology with Primetals. This British plant construction company had previously co-designed the FINEX* facility with POSCO. Following the agreement, the design process for the HyREX test facility began. This test facility is scheduled to be introduced in 2026 to verify the possibility of commercialization. POSCO aims to achieve its “2050 carbon neutrality” goal by completing the development of commercial HyREX technology by 2030. The plan further includes a gradual conversion of existing blast furnace facilities at Pohang and Gwangyang Steelworks into hydrogen reduction facilities by 2050.

*FINEX : This is a facility based on proprietary technology developed by POSCO, which achieved the word’s first commercialization in 2007. The FINEX process eliminates the step in which raw materials are pre-processed, instead directly using inexpensive powdered iron ore and bituminous coal to produce molten metal.

POSCO is playing a pivotal role in achieving carbon neutrality in the global steel industry

POSCO has been continuously conducting R&D towards the commercialization of hydrogen reduction Ironmaking, and has been putting considerable effort into forming alliances with global steelmakers to achieve carbon neutrality. In particular, in 2021, POSCO held the world’s first Hydrogen Iron & Steel Making (HyIS) Forum in Seoul. The event brought together global steelmakers, worldwide steel associations, raw material suppliers, energy and engineering companies, and officials from the government and international organizations. To prepare for the era of carbon neutrality, POSCO has been playing a pivotal role in the steel industry by sharing its insights to speed up the transition to hydrogen reduction Ironmaking technology. In addition, POSCO has been actively presenting its vision and goals for carbon neutrality to the international community by participating in the Green Materials Forum, Carbon Neutrality Expo, and World Climate Industry Expo.

POSCO’s hydrogen reduction Ironmaking technology is a national initiative

The hydrogen reduction Ironmaking cannot be accomplished by POSCO alone. It requires national support and attention, just like 50 years ago, when the Korean government recognized the necessity of the steel industry and was totally committed to promote the construction of an ISM. At that time, the government actively supported the construction of steel mills through site renovation, infrastructure development (including railroads, ports, and dams), and the enactment of the Steel Industry Promotion Act. Thanks to these efforts, the Korean steel industry has gained global competitiveness today.

In order for Korea to lead the paradigm of the steel industry again and seize new opportunities, active policies and support mechanisms led by the government and relevant government agencies should be established. This is because the transition to hydrogen reduction in steel production is an unavoidable prerequisite and a survival strategy for the national industry.

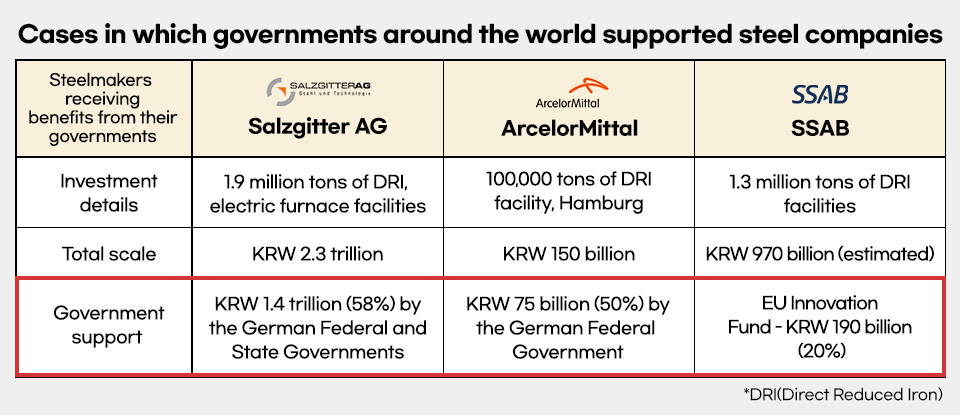

Governments around the world that have insight into this trend are offering unprecedented support to steel companies. The German Federal Government has decided to provide KRW 75 billion to ArcelorMittal Hamburg steel plant, while the German Federal and State Governments have decided to provide KRW 1.4 trillion to the steelmaker Salzgitter. The EU also provided KRW 190 billion from an innovation fund to Swedish steelmaker SSAB, which contributes to the transition to green steel. In this context, countries around the world are accelerating the establishment of infrastructure for a carbon-neutral value chain with direct funding by setting agendas at the government level.

To survive in the global competition for a new paradigm, there’s a great need for policy support for HyREX development and government-level construction of infrastructure to boost the price competitiveness of hydrogen. Designating hydrogen reduction Ironmaking technology as a national strategic technology is essential. This technology is directly linked to national competitiveness and is necessary for maintaining international competitiveness in the steel industry, a cornerstone of manufacturing.

While celebrating the 50th anniversary of the ISM’s completion, POSCO will open the second stage of the steel industry with the fierce determination of the day when it took on a seemingly impossible challenge. As a leading player in the industrial renaissance of Korea, POSCO is also deeply conscious of its responsibility to protect the future of K-manufacturing. In the era of great industrial transformation called carbon neutrality, it is necessary to establish policies and institutional support for the steel industry to safeguard the competitiveness of the domestic manufacturing industry and turn the times into an opportunity for economic growth.

POSCO, which is at the center of such changes, will become a more solid company for the next 50 years based on the experiences and capabilities it has accumulated over the past 50 years.