With so many auto exhibits at CES 2017, one might be forgiven for thinking they had fast forwarded to the Detroit Auto Show. Alongside the computers, TVs, and smart household appliances, seemingly all of the major car manufactures were there (along with some new ones) to show that innovation is no stranger to an industry more than 100 years old.

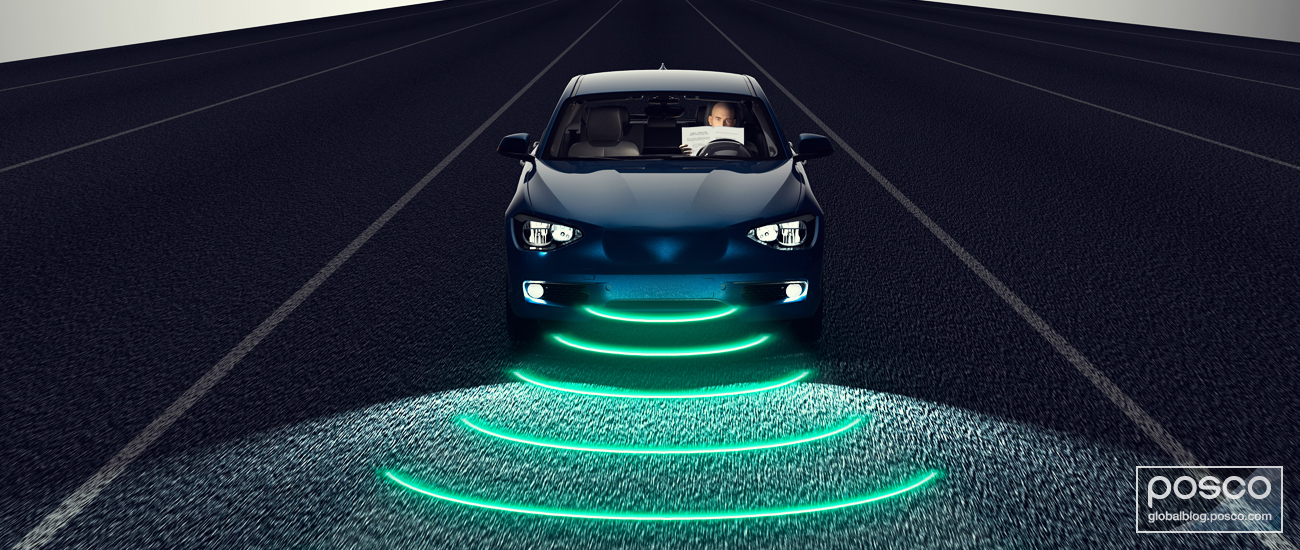

Advancements in electric cars, autonomous driving, car connectivity, and AI were on full display. Nissan and BMW unveiled plans to use Microsoft’s personal assistant technology, Cortana, with their cars. Honda became the first major manufacturer to develop an electric concept car specifically designed for ride-sharing. And as for self-driving cars – Nissan announced it would bring autonomous driving support to its Leaf electric car, Hyundai introduced one that would be affordable enough for the masses, and Audi announced a partnership with Nvidia to bring self-driving cars to market by 2020.

With all of the focus on electric cars and autonomous driving, it is easy to forget the basic building blocks that are needed to make these cars a reality. As Toyota Research Institute CEO Gill Pratt noted at CES, “Historically humans have zero tolerance of death by machine,” and for further adoption by the public, safety must be reinforced in autonomous vehicles. Increased safety in cars often goes hand-in-hand with heavier materials that can withstand more pressure. However, the push for more fuel efficient electric cars is pushing the industry to build with more lightweight components.

Car manufacturers are working to find the right balance between strength, weight, and price. The EPA has estimated that reducing a vehicle’s weight by 45kg (100lbs) will improve fuel efficiency by 1%, and while more lightweight materials do exist in aluminum and magnesium, they are often too cost-prohibitive for general use.

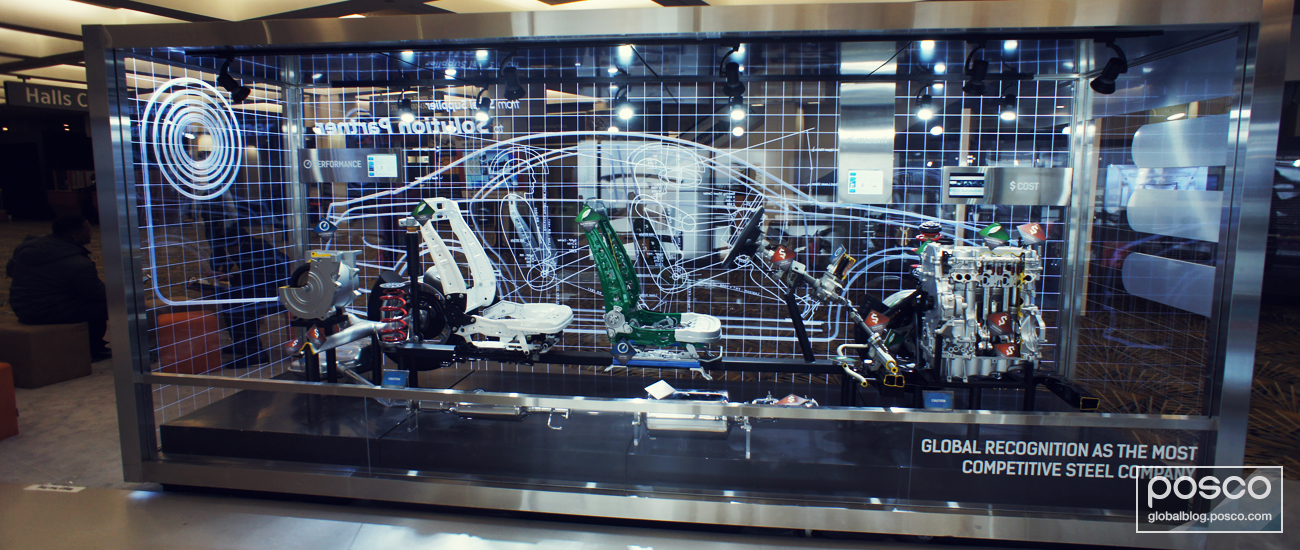

POSCO Body Concept Electric Vehicle

On this front, POSCO has been working to develop solutions for car manufacturers. The PBC-EV, or POSCO Body Concept Electric Vehicle, is one product of that research as POSCO sought to create a lighter car with the same strength and safety that is expected in today’s modern car market. POSCO focused on two main points when developing this lightweight car body. The first was the application of a combination of POSCO’s most advanced steels including TRIP, PosMCT950E, and PosMCT980B. Secondly, POSCO optimized existing construction methods and worked to introduce new techniques in order to both lighten and strengthen the body of the automobile. With its PBC-EV, POSCO was able to reduce weight by 26% while still maintaining the highest levels of body strength.

Magnesium technology

Many in the auto industry are setting their sights on magnesium as the future of car manufacturing. Magnesium can be easily molded and it is both lightweight and strong. Due to its high price, car makers have not fully embraced the move to magnesium yet, but POSCO is already preparing for this probability. Last month, POSCO’s World Premium Materials (WPM) – Magnesium Business Division organized a seminar with industry experts and automotive engineering students to discuss the future of magnesium in car manufacturing. Experts in magnesium, molding, bonding, and surface treatment were invited to speak about the application of magnesium technology in automobiles and students gave presentations on their own experience developing race cars.

Even though cars have been around since the late 19th century, new ideas continue to force the industry to adapt and change. And whether it is optimizing existing manufacturing processes or working to utilize technologies for the future, POSCO remains committed to finding innovations in the auto industry.

Don’t miss any of the exciting stories from The Steel Wire – subscribe via email today.

- 2017

- audi

- auto

- auto industry

- auto show

- automobile

- automotive

- autonomous driving

- BMW

- car manufacturing

- cars

- CES

- CES 2017

- ces2017

- design

- detroit

- electric cars

- Electric Vehicle

- engineering

- future

- future cars

- Hyundai

- industry

- iron

- lightweight

- magnesium

- magnesium technology

- partnership

- PBC-EV

- POSCO

- safety

- self driving cars

- solution

- steel

- steel maker

- tech

- technology

- vehicle