Norway 2025, England 2030, China 2035, Japan 2035.

What do these mean? These are the years set by each respective country to ban the sale of new vehicles with combustion engines — an initiative in response to climate change.

Automobiles are considered one of the best inventions of mankind. And recently, as environmental regulations have been strengthened worldwide, a sustainability-focused wave is trending in the automotive industry as well.

As actions to ban combustion engine vehicles have been accelerated from Europe to other countries, such as China and Japan, experts forecast that the annual production of eco-friendly vehicles worldwide, such as electric vehicles (EV) and fuel cell electric vehicles (FCEV), will increase from 6 million in 2020 to 39 million units in 2030.

In preparation for the advancing era of sustainable mobility, the sensible alternative for automakers is to develop EV or FCEV. Then what is POSCO doing in line with the paradigm shift in the automotive market? Of course, it has its own share of plans — responding with the integrated brand for sustainable mobility, “e Autopos”!

l POSCO Has It All Figured Out

sustainable mobility isn’t just a concern for the automotive industry. The steel industry also needs to develop materials appropriate for application in eco-friendly vehicles that are powered by secondary batteries or hydrogen fuel cells rather than engines.

Since POSCO is the top global automotive material manufacturer supplying automotive steel plates to top automakers in Asia, America, and Europe for over 50 years, what does it have to do with eco-friendly automotive materials?

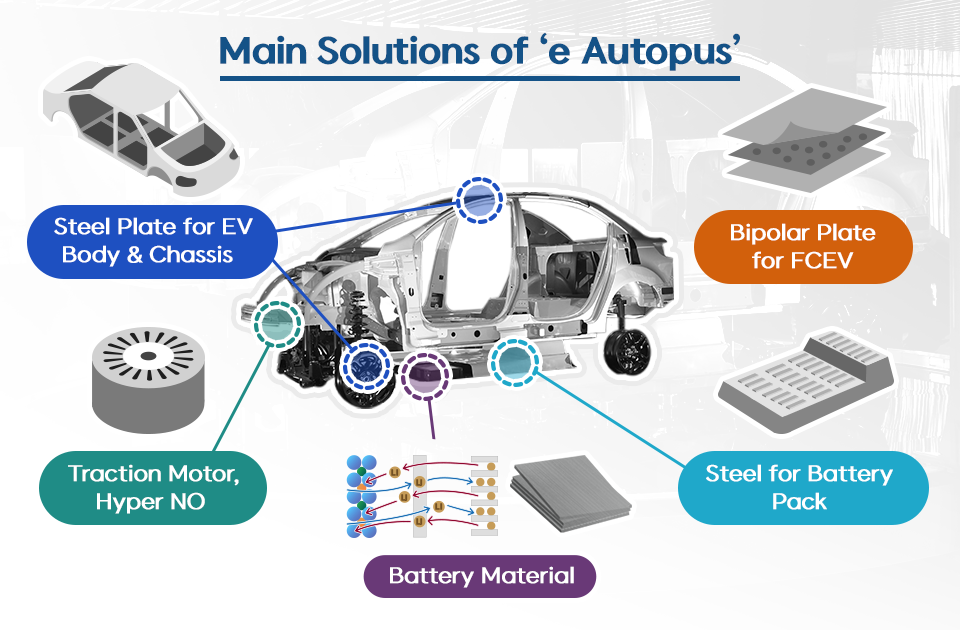

POSCO already developed and currently supplies various solutions, including the ultra high-strength “Giga Steel” for EV body, chassis, and battery pack, high-efficient “Hyper NO Electric Steel” for EV traction motor, which is a key component of EV, and “Poss470FC Stainless Steel” for the bipolar plate for FCEV that requires to be highly conductive, corrosion-resistant, and durable.

Also, together with POSCO Chemical, POSCO is the only Korean company supplying materials for secondary batteries, the heart of electric vehicles, from raw materials, such as lithium, nickel, and graphite, to cathode and anode materials.

Supplying automotive materials is only possible if knowledge of automobiles is sufficient. POSCO has accumulated technology and know-how for more than 50 years and has established a strong global partnership, thus making it the front player in the era of sustainable mobility. And “e Autopos” will be a brand proving its capabilities.

l “e Autopus,” POSCO’s Own sustainable Mobility Brand

On January 27, POSCO launched “e Autopus,” an integrated brand of eco-friendly automotive products and solutions to lead the eco-friendly automotive market.

“e Autopos” is a combination of the words eco-friendly and electrified AUTOmotive Solution of POSco, and it intends to pioneer the eco-friendly automotive market through innovation that comprises eco-friendliness, collaboration synergy, and future orientation.

As mentioned earlier, major solutions include high-strength steel for EV body and chassis, battery pack steel, energy-efficient steel for traction motors, bipolar plate for FCEV, cathode and anode materials for secondary batteries. Together with POSCO Chemical, POSCO International, and POSCO SPS, POSCO plans to provide steel products for eco-friendly automotives and secondary battery material products, and customized application solutions for clients as a whole package.

With the launch of “e Autopos”, POSCO plans to pioneer the eco-friendly automotive market in the future with its partner companies under the slogan “Drive Green Future, Together,” and aims to provide products and solutions to global eco-friendly automakers. POSCO will also establish a systematic sales infrastructure to increase client satisfaction.

POSCO Newsroom plans to introduce various solutions of “e Autopos” that are expected to drive sustainable mobility, such as EV body & chassis steel plates, energy-efficient steel plates for traction motors, steel for battery packs, battery materials, and bipolar plate for FCEV — all made with POSCO’s technology.