“POSCO offers the world’s most competitive steel products.”

Such a description isn’t inaccurate considering POSCO has topped the WSD (World Steel Dynamics) competitiveness ranking for 10 years straight.

But it’s not enough — yes, POSO was and still is a top steelmaker, but the values POSCO is creating goes beyond the realm of steel products. To reflect this reality, the more accurate description of POSCO today is: “POSCO provides the most competitive solutions to the clients.”

l POSCO — More than Products

The day-to-day steelmaking operation involves: melting iron ore to produce molten iron and making steel products as per client’s requests, be it hot-rolled steel, cold-rolled steel, wire rods, thick plate steel, etc.

For POSCO, that’s not the end of the story. POSCO’s sales tactic distinguishes itself from other steelmakers in that, when a client places an order, POSCO doesn’t immediately jump into the production. Instead, POSCO thinks ahead considering the whys and the hows: why does the client want and need this product? What are the best manufacturing/welding/assembly technologies to serve that purpose so the product can thrive in the market?

Let’s say a client places an order for a wire rod. Ultimately, the client would like to produce large bolts with POSCO’s wire rod. In this case, what POSCO sells to the client is not just the wire rod. What POSCO does is to sit down with the client and discuss the details of the end use: where will the bolts be used? POSCO thoroughly reviews the technologies involved, before heading straight into the production, so that the product can serve its best purpose.

If the bolts were intended for a steel structure, POSCO researches what joints will be connected, figuring out how the client can produce the most solid and durable bolts with POSCO’s wire rods. POSCO’s business approach is to provide the best possible solution for clients’ competitiveness, not just POSCO’s.

l POSCO Global R&D Center Spearheads Client Solutions

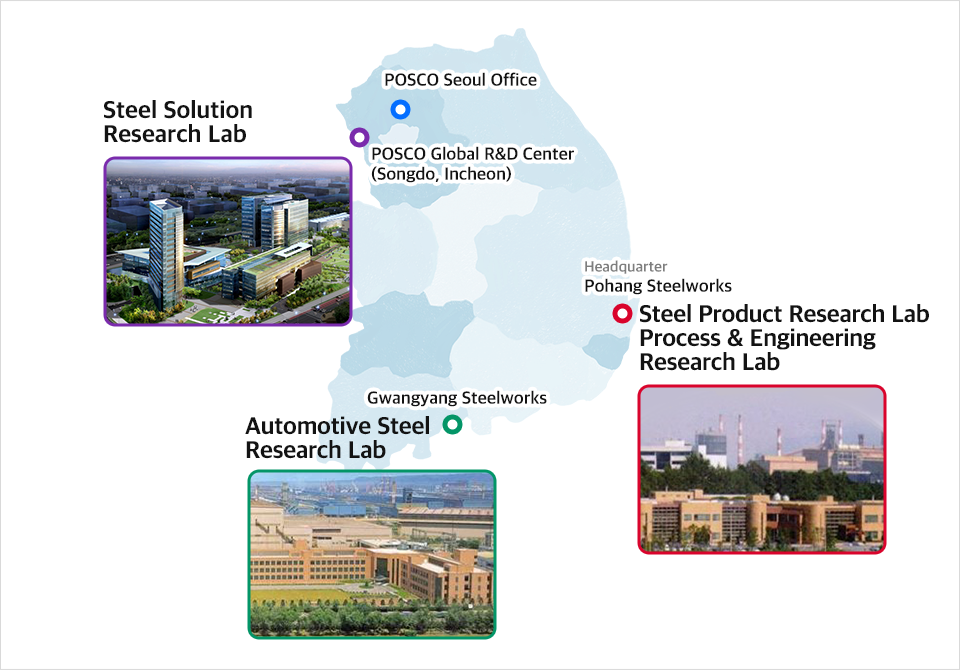

What enables providing POSCO solutions to clients? It’s the years of accumulated research on various properties and characteristics of steel materials. Currently, POSCO’s research facilities are located in Pohang, Gwangyang and Songdo: Steel Products Research and Process Engineering Research Group in Pohang; and Automotive Steel Application Center in Gwangyang.

Of all POSCO’s research facilities the Steel Solution Research Lab in Songdo, Incheon spearheads client solutions.

▲ POSCO’s research facilities

Over 80% of the researchers at POSCO’s Steel Solution Research Lab are Ph.D. researchers across various fields such as machinery, materials, architecture, civil engineering, etc. At POSCO’s cutting-edge, state-of-the-art research facilities, the company develops top solutions for clients from various industries including automotive, home appliances, electrical steel sheets, stainless steel products, construction, ships, machinery, pipelines, etc.

To optimize its capacity to develop client solutions, the Steel Solution Research Lab in Songdo restructured its departments into the following four groups this year: Materials forming research; Materials performance research; Steel structure research; Welding and Joining research.

In addition, the Steel Solution Research Lab collaborates with the marketing department in Seoul as well as with the Steelworks in Gwangyang and Pohang, playing a role in developing customer solutions, support, and timely supply of solution products.

l POSCO Solution Targets Client Success

The recent collaboration with Austem, an auto parts manufacturing company, is a good example of the solution development at POSCO Global R&D Center.

Austem provides key auto products such as chassis, body, steel wheel, and seat — through domestic and overseas businesses, Austem has annual sales of over 400 billion KRW. Austem has been POSCO’s long-term client since 1990, and the company shows a solid growth record through its existing products as well as new technologies.

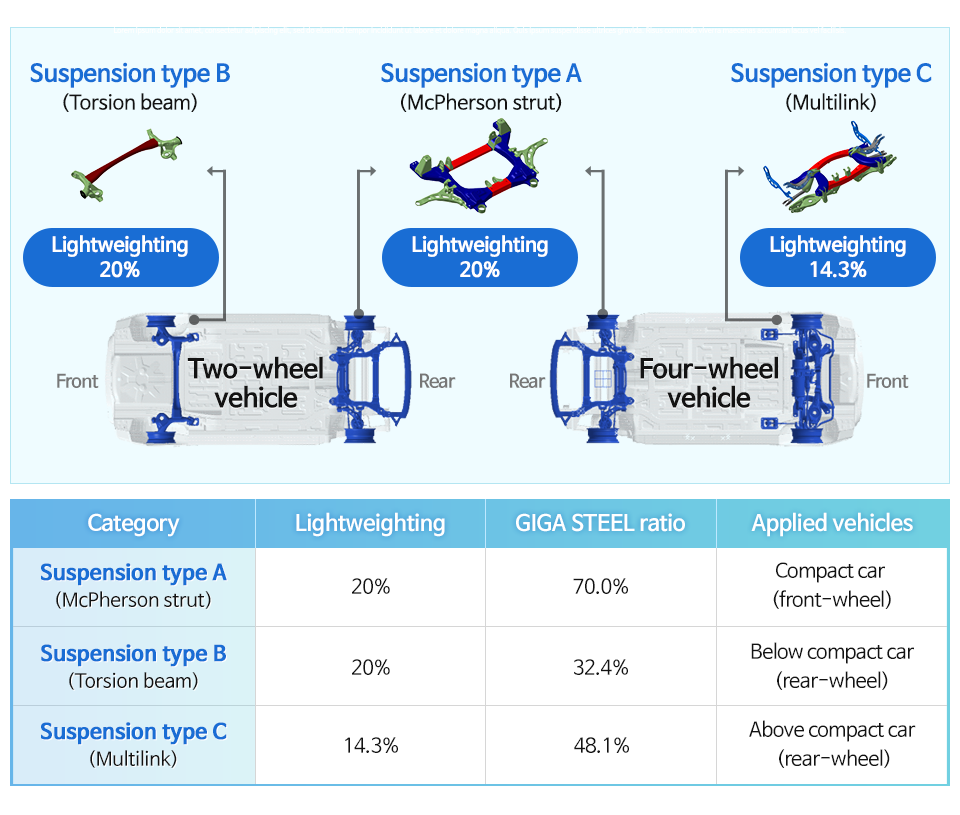

As the auto market shifts towards sustainability, efforts are being made to make more eco-friendly cars such as electric vehicles and to reduce car weight. In such milieu, lightweighting auto parts such as suspension which absorbs the road impact to enable stable driving emerged as an important factor.

Despite the global tendency where automakers opt for aluminum to lightweight suspensions, POSCO has been focusing on developing steel suspension since 2016, through its partnership with Austem.

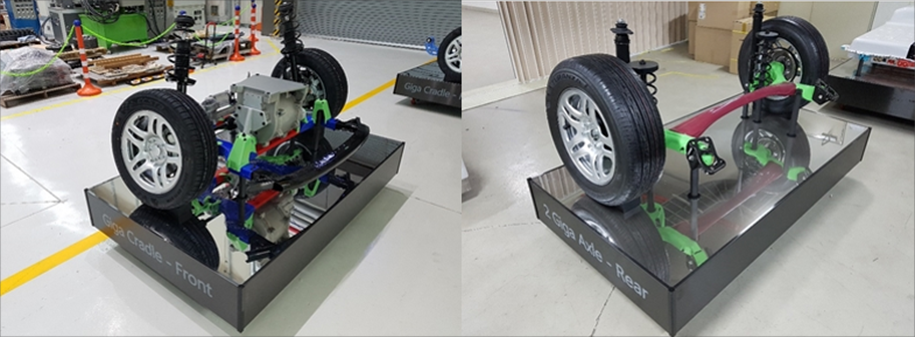

The two companies applied GIGA STEEL to suspension parts — conventionally, giga-grade steel was never applied to suspension. POSCO’s new approach led to an optimal design technique to secure lightweight without compensating the current level of performance.

Per suspension type, the weight was reduced by 14.3% to 20%, thereby securing a steel solution that satisfies the suspension stiffness, strength, and fatigue performance.

With the new GIGA STEEL suspension, Austem is pioneering a new market where the product is being positively received in the global market.

Dong-Yoon Seok, a Senior Researcher at the Materials forming research group at the Steel Solution Research Lab, said, “To verify the performance of the product, we went through countless prototypes and tests at the R&D center and the Austem’s production lines.” He added, “Collaborating with a competent client and meeting the goal we’ve set was truly rewarding. That’s the type of solution development we aim for.”

▲The POSCO-Austem partnership replaces aluminum with GIGA STEEL for suspension.

Seok, also remarked, “The long-term partnership between the two companies helped build mutual trust which made the whole solution development process much easier. That was one of the big contributing factors for the good result.” — his remark signifies when developing solutions for client success, what POSCO focuses is the long-term success, not the short-term.

As POSCO contributes to improving clients’ technology and sales channels through its solution activities, POSCO’s high-quality steel products are being sold with the most optimized performance. This has distinguished POSCO from other contenders in the industry and that’s the path POSCO will continue to follow.

POSCO isn’t satisfied with simply making the world’s most competitive steel products. Instead, they want to be a steel company that offers the most competitive solutions to their clients.

※ At the time of Austem’s overseas expansion, POSCO’s Global Platform Business (GPB) program supported its entry into China. GPB was created to help partner companies expand overseas. To supply auto parts to China’s key automakers, Austem signed a joint venture with POSCO and established three production facilities in Suzhou (2008), Yantai (2014), and Wuhan (2016).