Technology development would be what SMEs(Small and Medium Enterprise) need the most for future growth. In reality, however, investment for this has been decreasing due to the staggering economy. According to KBIZ(Korea Federation of SMEs), in 2017, the investment rate for technology development — among SMEs of primary metal — recorded a mere 0.7% of the total sales.

Aware of the current situation, POSCO provides customized consulting of specialists to resolve problems or issues, which are liable to show up in SMEs. POSCO has been offering this service to its direct client companies, and now it has gone on to extend this service to the clients of its client companies as well. The reason why POSCO is interested in these secondary and tertiary business partners, is because POSCO is looking at the overall ecology of the steel industry, and finding ways to strengthen it. Hence, introducing another service of POSCO — ‘Maintenance Technical Support for Secondary Client Companies’

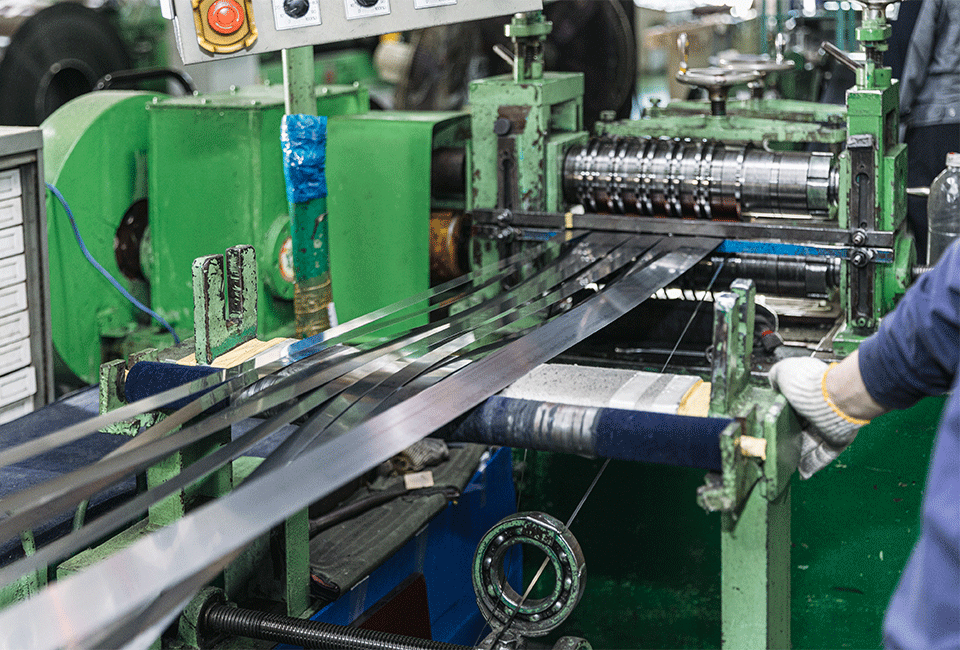

‘HK STEEL’ is a client company of ‘Hankum’ — one of POSCO’s client companies — and is currently producing ultrathin materials for automotive seat belt spring. Following Hankum’s recommendation, HK STEEL applied for POSCO’s maintenance solution, and POSCO stepped in more than willingly. POSCO Newsroom met with the CEO of HK STEEL and POSCO’s maintenance support team in charge, to discuss the technical support provided.

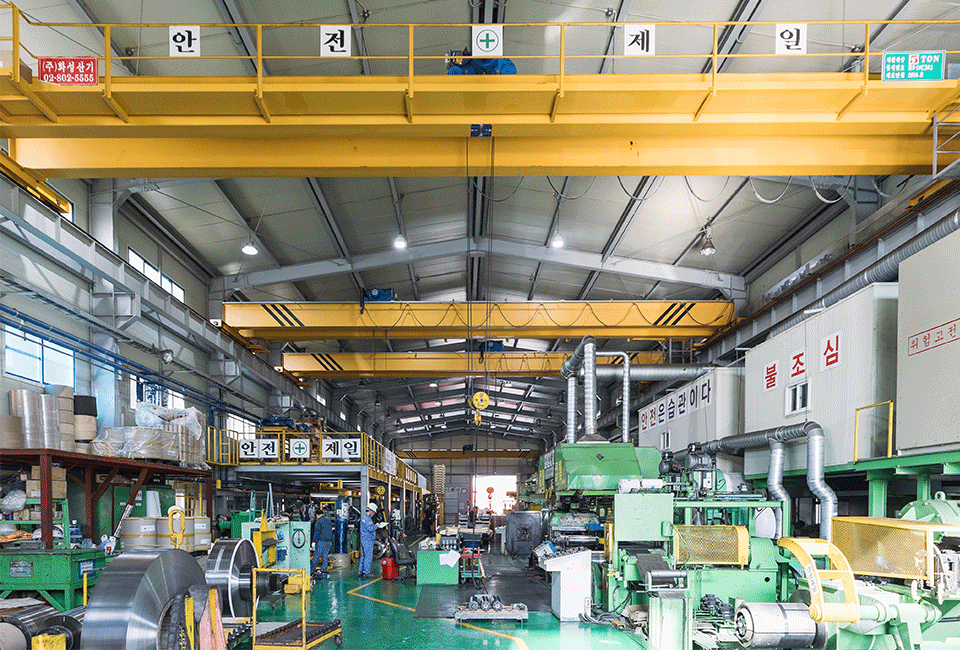

▲ HK STEEL is POSCO’s secondary client company.

l How Did POSCO’s Help Come So Far?

HK STEEL, located in Ansan, Gyeonggi-do, was established in January 2002. It is an SME with 15 employees including the CEO. The steel purchased from Hankum goes under secondary processing here and then sold to ‘Autoliv’ and ‘Asan Precision’. As seen here, HK STEEL doesn’t do any business directly with POSCO. Yet, it could still benefit from POSCO’s maintenance technical support. How was this possible? Let’s find out.

▲ HK STEEL CEO Hee-kwon Kim

“We have been purchasing primary processed steel from Hankum for 30 years. Recently there was a problem with the facilities in our company and when I talked to Hankum about it, they informed me of POSCO’s maintenance technical support. At first, I thought our company wouldn’t get the support since we do not have a direct partnership with POSCO. But POSCO accepted our request and agreed to take a look at our facilities. POSCO mentioned that secondary clients were POSCO’s clients too. So we asked POSCO for an overall inspection along with solutions regarding equipment — such as maintaining the horizontal level of the rolling mill, the operational status of the hydraulic plant and how to maintain it, the power quality, and so on.”

Hee-kwon Kim, CEO of HK Steel, said that working on technology development and facility maintenance is difficult due to lack of personnel and fund. That’s why POSCO’s support — complimentary help from experts — is like a blessed rain after a long drought for him.

“There are five or six companies that produce products with just one or two rolling mills, here in Ansan alone. All the CEOs of the companies tell me that whenever there are technical problems, it is because they are short on funds. But then again to solve the problems, they need more funds. It’s like a vicious circle. For SMEs, equipment maintenance is an incessant issue. I was quite worried as well. But now that POSCO’s experts have taken over, I can’t be more reassured.”

POSCO’s service doesn’t end in just maintenance technical support alone. Kim also added that POSCO meets with Autoliv — a client company of HK STEEL — and Hankum every quarter to discuss products.

“Our company produces springs for automotive seat belts, and there are some researchers who give us advice at POSCO. Along with these experts, we discuss quality with our client companies. Not just that, POSCO also analyzes the product and sends the report back to us. Thanks to POSCO, both our company and our client companies are in a win-win situation with more competitive products.”

Mr. Kim added, “For the manufacturing industry — including the steel business — to break through the current staggering economy, large companies and SMEs need to work together. In this sense, POSCO is doing great things by expanding the solution program to SMEs, who are in much need of it. With this help, SMEs can grow more and this would eventually boost the manufacturing industry. So I wish that other SMEs would also get to know about this solution program.”

l “It’s a Great Pleasure to be of Help”

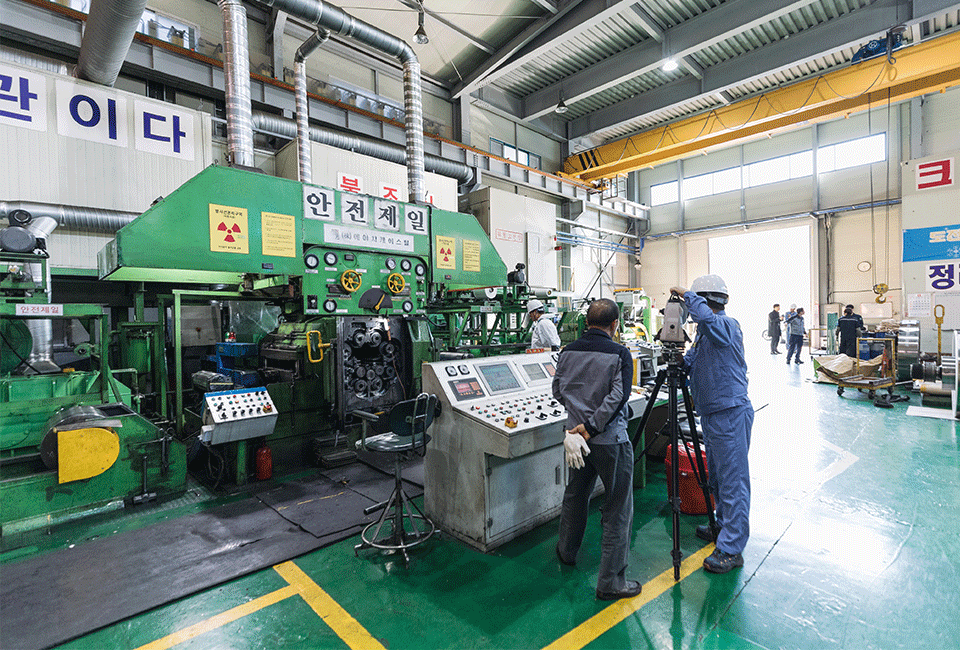

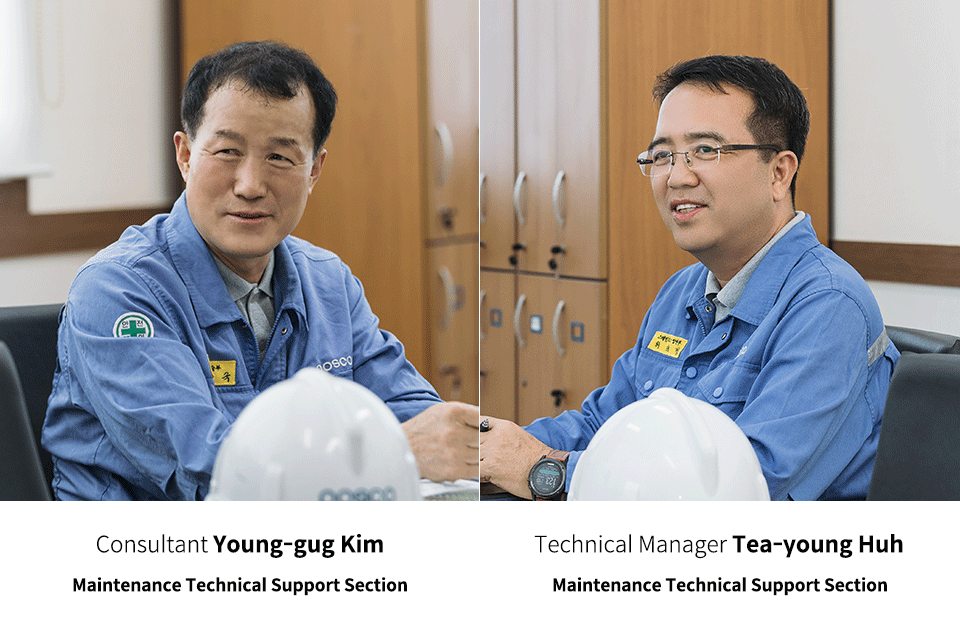

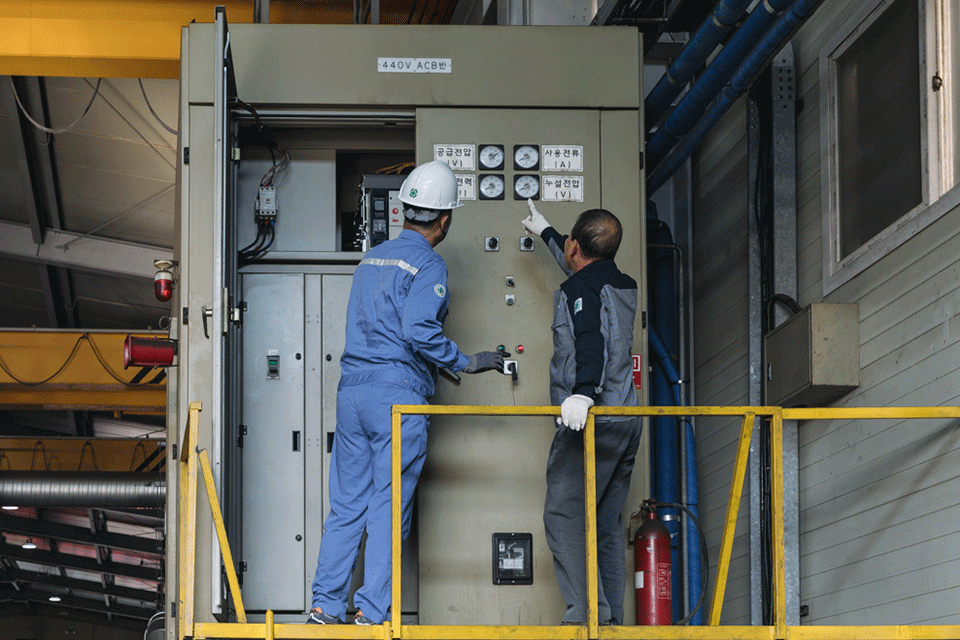

Four field experts from Pohang Works were at work when newsroom visited HK STEEL. This time they were staying for two days to look into the maintenance. Newsroom met with Technical Manager Tea-young Huh and Consultant Young-gug Kim — who both have over 30 years of field experience. They are ‘field’ experts assigned here with the essence of POSCO’s 51 years of technology. They’ve been going around the country and sharing their skills and experience.

Q. What are you helping with HK STEEL today?

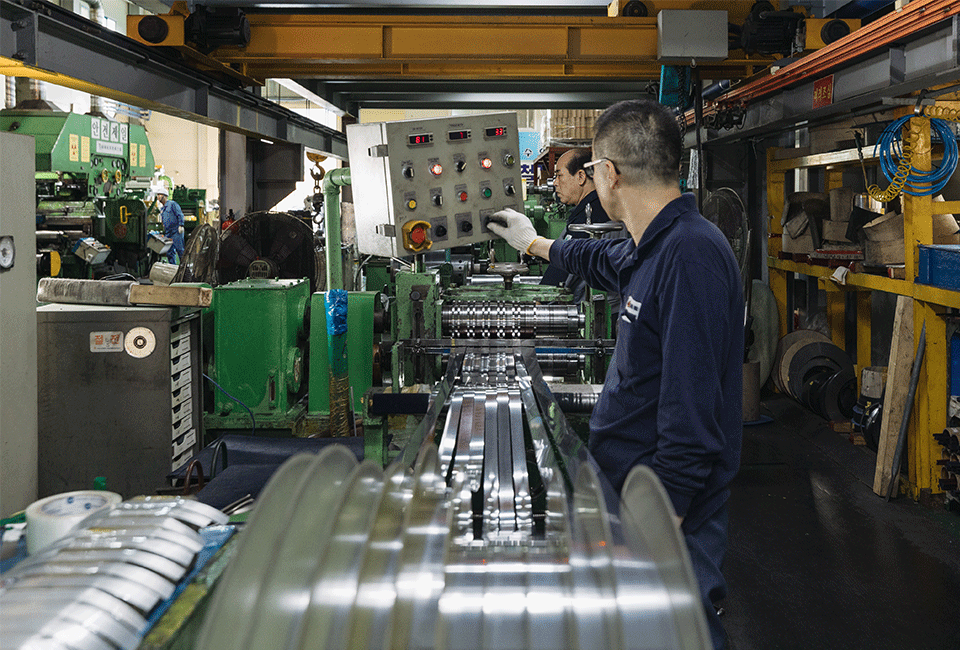

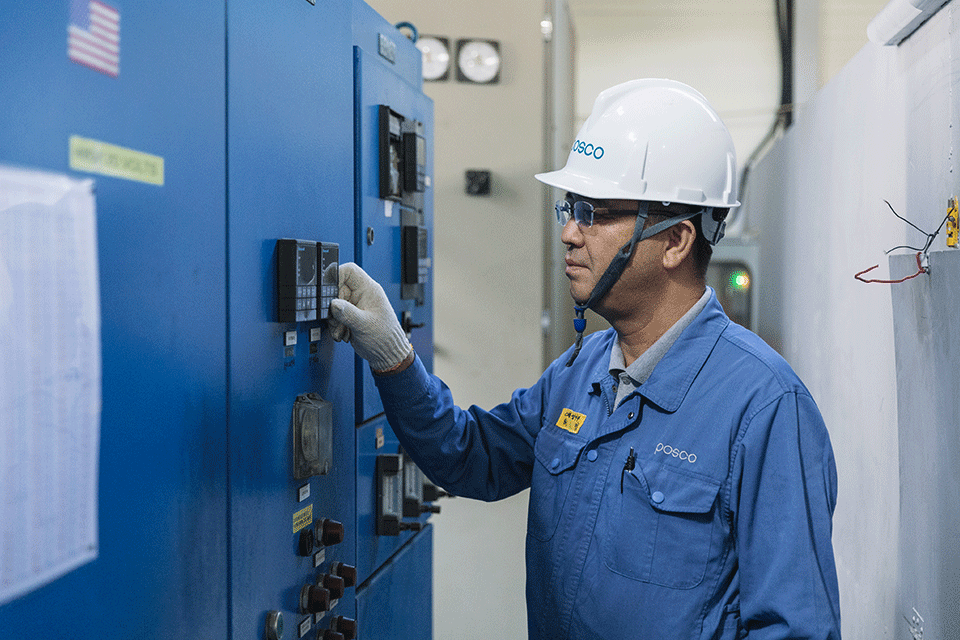

Mr. Huh: I am in charge of the PLC (Power Line Communication) control and the drive that runs the motor. I am inspecting the maintenance control so that it runs stably and doesn’t affect product quality.

Mr. Kim: I am in charge of the entire power distribution system — a system that receives electricity from the power plant and distributes it — and this time I will examine the quality of the electricity that HK STEEL uses. If electricity supply isn’t stable, several problems might appear so I check several factors, like the power factor, harmonics, transformer load factor, breaker protection devices, and so on, with diagnostic equipment. After inspection, a report of the current status follows and if there is any improvement needed, we provide technical support.

Q. How was your inspection? What solution did you give?

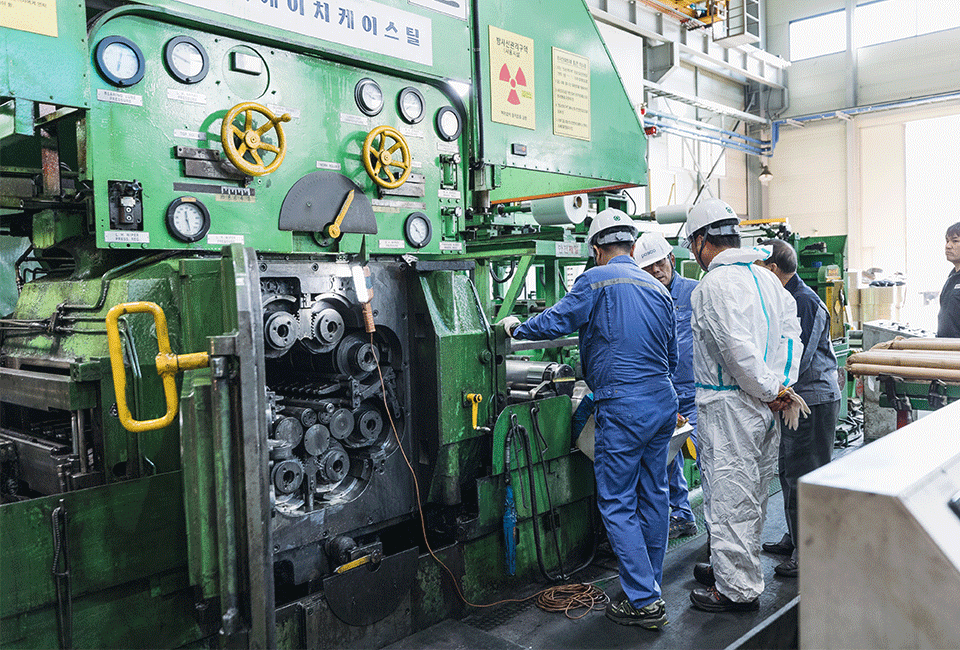

Mr. Kim: Before the actual consulting, We came here and took a look at the facilities around two weeks ago. We also asked what HK STEEL needed. They said that they had a problem with the rolling. The quality wasn’t as good as it used to be. Today after inspecting, I saw that the alignment of the rolling mill was slightly dislocated, and there was a problem with the Automatic Gauge Control (AGC) — a thickness control system. This may sound simple, but these are subtle errors that are hard to find by just looking, without any expert equipment or knowledge. The problem is that these errors can cause degradation in the quality of the end product.

Mr. Huh: We’ve readjusted the mill alignment and made sure that the control system works accurately. Accordingly, the flatness of the steel will get better which will, in turn, enhance product quality. I hope this would help boost the client company’s sales as well.

Q. You must have visited a lot of SMEs. Have you had any memorable experiences?

Mr. Huh: Last year, I visited a client company in Gimpo. Its factory was submerged due to a big flood that year. The company didn’t have a specialized person in charge of electricity, and the plant manager managed the electricity by himself. After the flooding, the whole factory experienced a blackout and nobody knew how to power back the electricity. So they brought in a technician and it took three days to get the line working. After this incident, our team visited multiple times to draw an electric schematic diagram of the plant and number the panels.

Mr. Kim: I remember that one too. There was a big typhoon that next year too and caused another problem with the electricity supply. However, at that time, they looked at the electrical schematic diagram that we gave them, and they could bring back the power easily, minimizing the downtime of the plant. Drawing the electric diagram — that could be easily understood — was quite a challenge because it is usually hard for non-experts to comprehend. I had to travel back and forth from Pohang to Gimpo several times because of that, but when I got a call from them saying that it helped a lot, it was all worth it.

Q. The CEO of HK STEEL mentioned that the service doesn’t end with just maintenance technical support alone. What’s more?

Mr. Kim: e are trying to solve the weaknesses and chronic problems, that our client companies experience, with POSCO experts. In addition to maintenance technical support, we provide solutions in various areas such as marketing, safety, energy, IT, and so on, which means that our support contributes to the growth of our client companies, not just in resolving problems.

Mr. Huh: We try to help in all areas possible if it is of help to our client company’s business. I think this could be the cornerstone of the POSCO vision — ‘Building a Better Future Together’.

Q. What does this project mean to you and what are your future goals?

Mr. Kim: Now that I can share my experience and skills where it’s needed, I feel that I’m really contributing. Whenever I resolve client companies’ problems and see them thrive, I am so happy for them. I believe that my role and mission is to aid client companies for a better future together.

Mr. Huh: I expect the credibility between POSCO and client companies will increase through these support programs. I learn a lot myself through these POSCO maintenance technical support activities, too. I would like to work on providing more solutions in the future as well.

‘Maintenance Technical Support for Secondary Client Companies’ program is part of POSCO’s efforts to help SMEs facing this reality. POSCO spares no time and effort on the mutual growth of POSCO and all its client companies, business partners and suppliers. Through this, POSCO hopes to strengthen the steel industry ecology and make sure that POSCO steel becomes products of the highest quality for consumers.