To reduce CO2 emissions, automakers have been working toward lightweight solutions that help build more fuel-efficient cars. However, the production emissions of some light weighting materials are so high they offset any benefits gained.

POSCO GIGA STEEL was developed to provide automakers with a high strength, lightweight material solution that also produces significantly less production emissions and is completely recyclable. Take a look at our infographic to find out more about POSCO GIGA STEEL and the benefits it offers for automakers looking for lightweight, sustainable steel solutions.

In this contribution article, Dr. Roland Geyer, associate professor at the Bren School of Environmental Science and Management at the University of California at Santa Barbara, explores why we need to move beyond fuel efficiency as the sole determinant in measuring a car’s sustainability. Dr. Geyer argues that we need to look at the full life cycle of a car – from production to disposal.

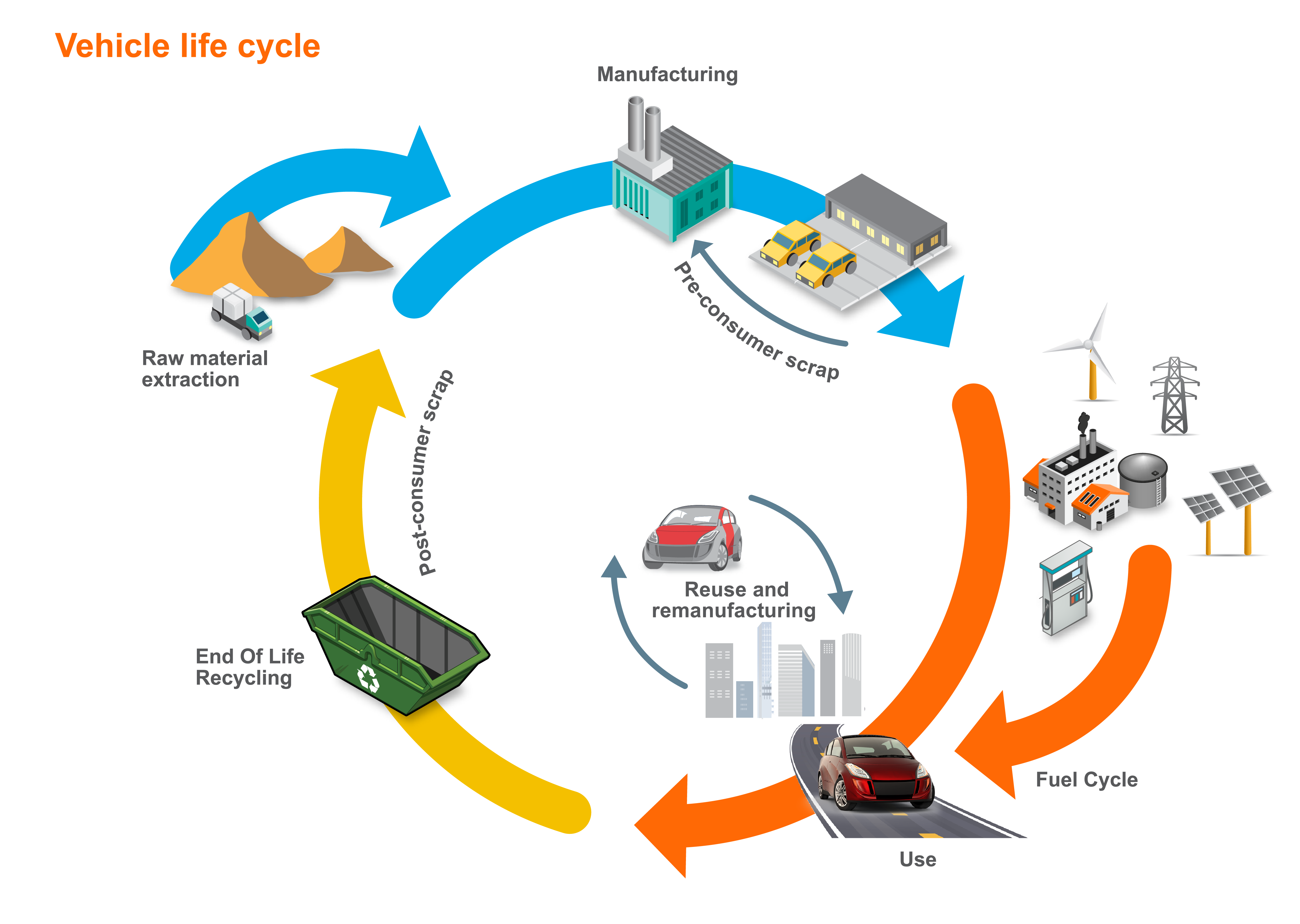

Policies with the goal of reducing climate change impacts from cars focus on reducing tailpipe emissions. While automakers can respond by improving fuel economy with lightweight materials, this can lead to an increase in carbon emissions over the life of a vehicle. Taking a lifecycle approach to automotive environmental policy—from production to disposal—helps avoid such unintended consequences.

Tailpipe Mitigation is Not Enough

Most climate impacts from internal combustion vehicles come from tailpipe carbon dioxide (CO2) emissions. The other life cycle stages, which include vehicle production, fuel production, and vehicle disposal, have much lower greenhouse gas (GHG) emissions. Understandably, therefore legislators focus on curbing tailpipe CO2 emissions and increasing fuel economy. However, automotive climate policy with an exclusive focus on tailpipe emissions opens the door to unintended consequences. This is equally true for vehicles that use biofuels, electric power trains, or lightweight materials to increase fuel economy.

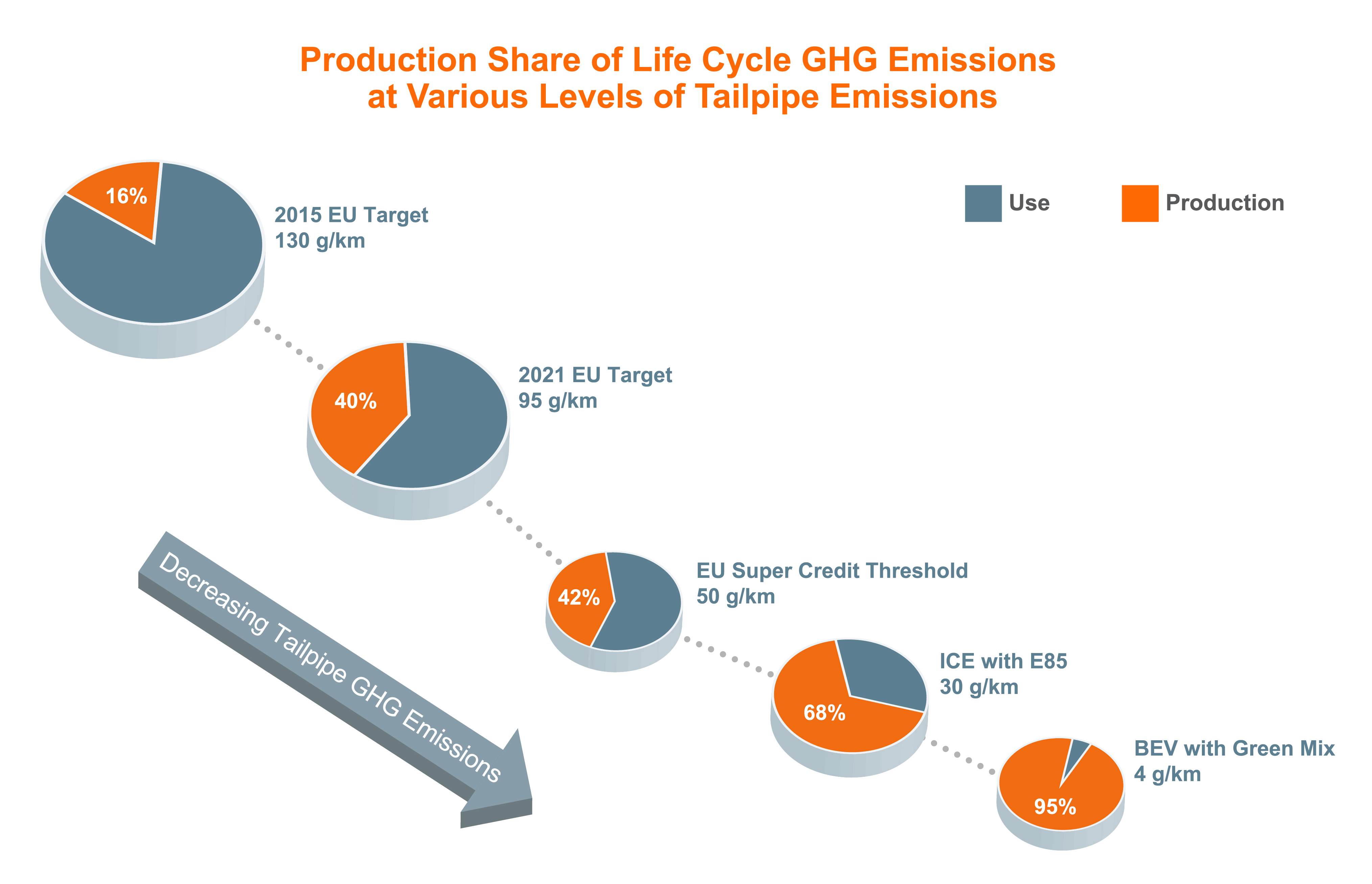

As use phase emissions are minimized, Production phase share of emissions in the total life cycle increases significantly.

Critics of biofuels contend that they can cause, directly or indirectly, more GHG emissions than they avoid. Skeptics of electromobility argue that the GHG emissions of producing electric vehicles—and the electricity to drive them—can outweigh their lack of tailpipe emissions. The production of lightweight materials is typically GHG-intensive, so their widespread use would significantly increase the climate change impact of vehicle production. Good environmental policy aimed at reducing climate impact from vehicles, therefore, needs to consider these “upstream emissions,” which could severely compromise or even negate their climate change mitigation goals.

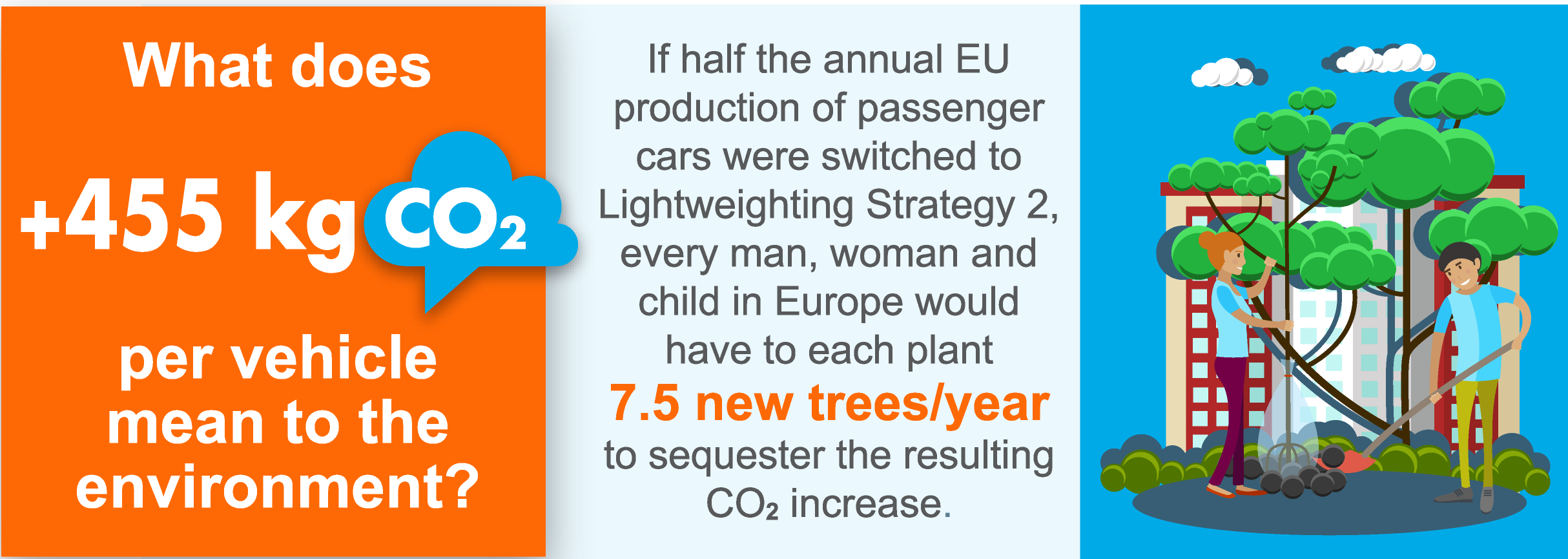

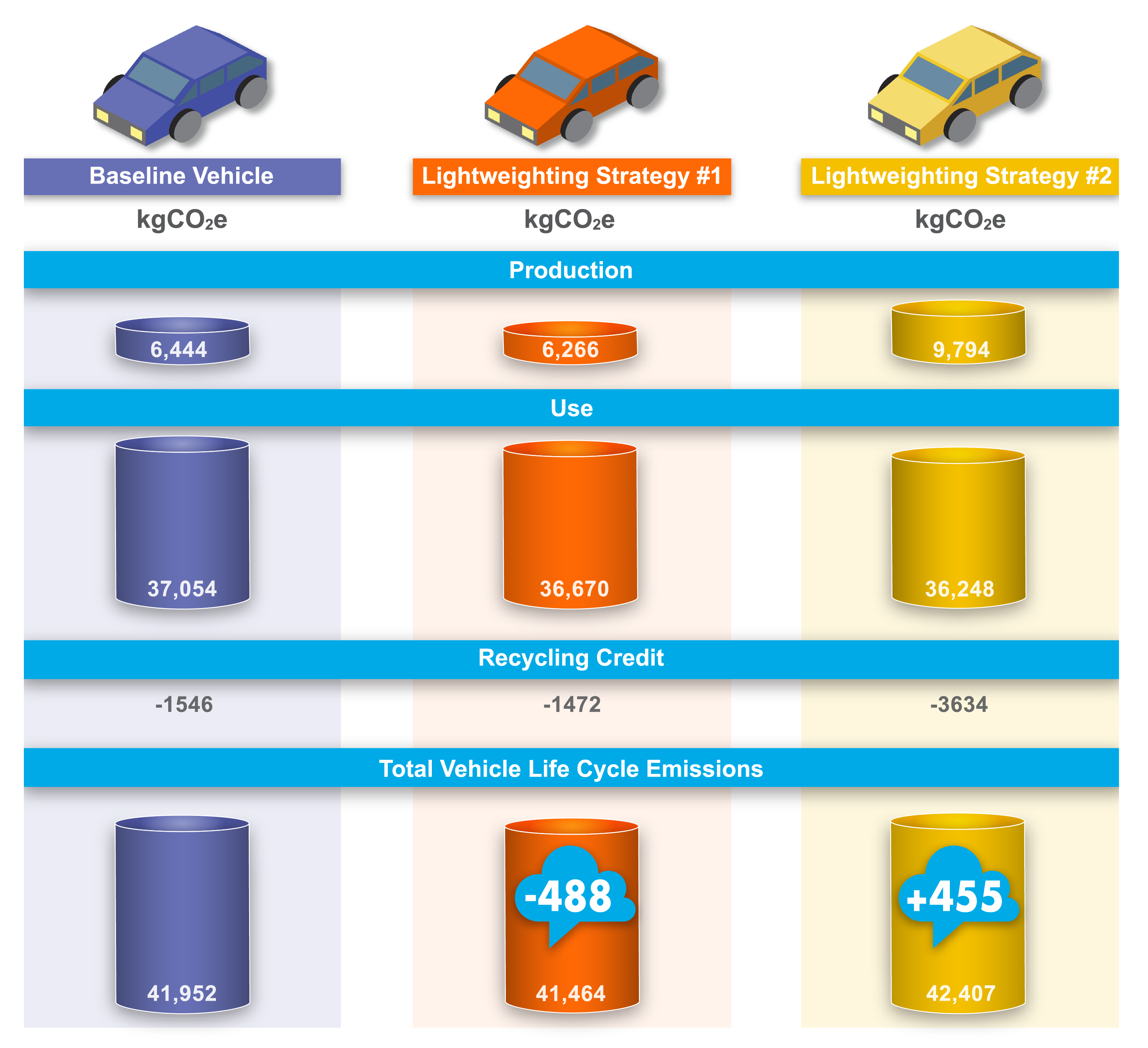

Without LCA, some lightweighting strategies can lead to a net increase in total life cycle emissions—an unintended consequence.

The Unintended Consequences of Vehicle Lightweighting

Vehicle lightweighting, in particular, poses a threat to effective automotive climate policy. Lightweighting can increase total climate impact and defeat the purpose of the policy since the increase in emissions from vehicle production can be larger than the emissions saved due to improved fuel economy. The trend of increasing drive-train efficiency and decreasing carbon intensity of fuels and electricity will further reduce any benefits gained from decreasing the weight of the vehicle. The importance of addressing the unintended consequences of tailpipe-only regulation, therefore, will only grow in the future.

Therefore the 2014 revision to the EU’s regulation on CO2 emissions from new passenger cars states that “policy action should […] ensure that those upstream emissions do not erode the benefits related to the improved operational energy use of vehicles.”

Life Cycle Assessment Helps Avoid Unintended Consequences

The only way to avoid unintended consequences is to use life cycle thinking and life cycle assessment (LCA). LCA is a mature environmental assessment tool with global standards and close to 50 years of development and practice. It provides a rigorous methodology to account for all emissions generated during the life of a product, making it the ideal tool to identify and quantify environmental trade-offs.

Today LCA is widely used by academia, industry, government, and non-governmental organizations. Together with academia, companies and industry associations are leading the way in the deployment of LCA. Most car manufacturers are already using life cycle thinking and LCA, which is equally accepted by material producers.

Environmental agencies around the world support LCA, including those of the European Commission, which call it the “the best framework for assessing the potential environmental impacts of products currently available.” Life-cycle-based environmental regulation is in its infancy and not without challenges. Nevertheless, environmental regulators and policymakers have begun to draft legislation with a life cycle perspective, such as California’s Low Carbon Fuel Standard. The regulation of automotive GHG emissions provides a unique opportunity to align regulatory practice with the state of the art in environmental product policy and launch a new area of successful environmental legislation free of major unintended consequences.

| Dr. Roland Geyer is an Associate Professor at the Bren School of Environmental Science and Management at the University of California at Santa Barbara. Professor Geyer’s work focuses on the life cycle of manufactured goods and in the environmental and economic potential of reuse and recycling activities. He also studies the evolution of green business plans, a model that relates corporate financial performance to corporate environmental performance. He has also worked extensively as an advisor to the steel industry as it evolves and creates better products that can be made with fewer resources.

For more information on automotive steel and life cycle assessments, please visit World Auto Steel. |