Join POSCO Newsroom for the final story of INNOVILT Alliance Journal! The seventh story is about the visit to LIVING KITCHEN CO., LTD, a manufacturer of kitchen sink bowls.

LIVING KITCHEN CO., LTD. is situated in Yesan, Chungcheongnam-do, about a two-hour drive away from Seoul. There might be some wondering why POSCO Newsroom chose LIVING KITCHEN CO., LTD, a kitchen sink bowl producer, for the last story of the INNOVILT Alliance Journal. And the reason is as follows.

In October 2020, POSCO had unveiled its 4th INNOVILT certified product. A total of 30 products acquired the INNOVILT certification, and amongst the many unfamiliar names of construction material products stood a rather familiar product — a kitchen sink bowl. A sink bowl? It was new to see an everyday item receive the INNOVILT certification. This made us curious about the production process of the INNOVILT sink bowl as well as the company that, for the first time in consumer products, succeeded in attaining the INNOVILT certification. Join POSCO Newsroom as it unveils the details.

l What Makes the INNOVILT Sink Bowl of LIVING KITCHEN CO., LTD. So Special?

▲ Sung-Wook Hong, Representative Director of LIVING KITCHEN CO., LTD., is explaining about the Quadra and Jumbo sink bowls

Established in 1999, LIVING KITCHEN mainly produces various stainless steel kitchen furniture and specializes in kitchen sink bowls. Everyone knows that stainless steel is an indispensable material when it comes to sink bowls. So, what makes the sink bowls of LIVING KITCHEN more special? Sung-Wook Hong, Representative Director of LIVING KITCHEN CO., LTD., said, “We make sink bowls with 100% POSCO stainless steel STS304.” According to Hong, sink bowls in Korea do not go under additional processing on the surface from the raw material stage to the end product. And so, this makes the surface condition of the raw material important. LIVING KITCHEN had previously received materials from other companies as well as POSCO. However, since three years ago, it has been using only POSCO stainless steel.

Since most companies appearing in the INNOVILT Alliance Journal adopted 100% POSCO materials, we wanted to know if any other reasons set aside the INNOVILT sink bowls from other products. Executive Director Sung-Wook Hong replied, “The steel grade that we use is not the conventional STS304. It is a new type of STS304 for sink bowl application that we researched and developed with POSCO. And this was the material used in the LIVING KITCHEN Quadra and Jumbo sink bowl series.”

In-Sik Lee of POSCO Stainless Steel Marketing Office added, “STS304* is the most widely used steel grade among POSCO stainless steel products. The STS304, currently provided to LIVING KITCHEN, is a renovated product specialized for application on sink bowls. It was developed by adjusting ingredients and materials at POSCO R&D Center. Compared to products of other companies, there is a distinct difference in quality. While conventional stainless steel has a milky color, the sink material supplied to LIVING KITCHEN has a mirror-like surface. Shaping has also become easier.”

▲ STS304 that POSCO provides for sink bowl application is laid out in front of LIVING KITCHEN CO., LTD.

l POSCO & LIVING KITCHEN CO., LTD: More Research for a Better Product

▲ Executive Director Sung-Wook Hong and POSCO’s In-Sik Lee in a conversation

LIVING KITCHEN is not just a company that produces sink bowls. It possesses all capabilities from product and mold design to actual production. The company develops more than five new products each year and brings them to the market. Then, how did the company come up with the INNOVILT-certified Quadra and Jumbo kitchen sink bowl series?

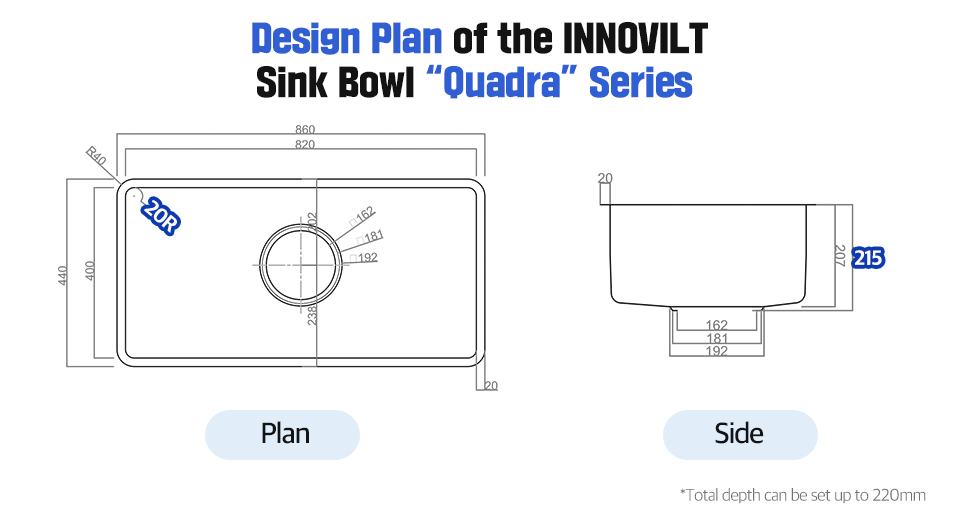

Executive Director Sung-Wook Hong said, “The latest trend in sink bowls is reducing unnecessary space around it. More and more consumers are looking for a simple yet “efficient” sink bowl. So recently, demands are much higher for right-angled sink bowls rather than round ones.” The “efficient” feature of the sink bowl refers to how wide and deep space can be used within the two-dimensional plane. In other words, it’s about maximizing the application of the three-dimensional space. A typical sink bowl has an internal angle of 100R* and a depth of 190mm. LIVING KITCHEN set on developing products with 220mm deep and an internal angle of 20R or less. *R stands for radius, and the lower the number, the closer it is to a right angle.

Some might think that making a sink bowl is easy since it just looks like stainless steel bent a little. However, the development process was like a rough mountain to climb. Hong briefly recalled the long period of collaboration with POSCO. He said, “At first, we started a sample test with POSCO’s conventional STS304. We developed a new mold (cast) in line with the recent trend and repeatedly improved the equipment. However, despite repeated tests, the sample product kept bursting open.”

To make a wide and deep sink bowl, reducing the internal angle is essential. However, if the internal angle is reduced in the molding stage, the desired depth cannot be attained. Representative Director Hong said, “Steel materials have a mechanical property of breaking when a force exceeding a certain strength is applied. The limit differs for each steel material, and we concluded that it would be difficult to adopt the conventional STS304 to our product. We needed a new solution from the material stage.” Representative Director Sung-Wook Hong decided to take on the challenge with POSCO and go beyond the limits.

LIVING KITCHEN asked POSCO for advice, and POSCO Steel Solution Research Center and POSCO SPS, a steel processing company, stepped in to help. POSCO’s In-Sik Lee explained the collaboration process. “With the samples made at LIVING KITCHEN, POSCO researchers examined whether defects occurred because of the material or the mechanics. Based on the test results of the researchers, we succeeded in realizing the current quality by improving the conventional STS304 so that it can be suitable for the sink bowls of LIVING KITCHEN.”

Director Hong added, “POSCO was really quick to respond. Actually, the speed of response is important when it comes to collaboration between a steel company and its manufacturers. There are even times when the release of a new product is delayed by a month or two due to the late response. However, POSCO’s response was so fast that we were able to introduce the new products of high quality quickly.”

The cooperation between the two companies was not limited to the development of materials and product shapes. When you look closely at some sink bowls, you can see a pattern engraved on them, and this pattern is what makes the scratches on the sink bowl less noticeable. Therefore, many manufacturers opt to place a pattern on their sink bowls. Interestingly, the same pattern is used by all domestic sink bowl manufacturers. This is probably because developing a new pattern demands considerable cost and time. However, LIVING KITCHEN did not settle for this option. It knocked on the doors of POSCO once again to develop a unique pattern that is narrower than the conventional pattern. LIVING KITCHEN designed the pattern, POSCO’s technical team inspected it, and POSCO SPS developed a mold that enables it to be engraved on raw materials. The result was a huge success! LIVING KITCHEN came up with a narrower pattern compared to the conventional one and successfully applied a patent for it.

l First INNOVILT Certified Sink Bowl in Korea, Quadra & Jumbo

The sink bowl created by the collaboration between the two companies is Korea’s first INNOVILT sink bowl Quadra and Jumbo series. The Quadra series is a square sink bowl with a depth of 220mm and the inner angle reduced to 20~25R. It is made of STS304 for sinks developed with POSCO using a one-touch mold method and features a deep and spacious washing space and a neat design. The Jumbo series, a more popular type of sink bowl, also adopts STS304 for sinks. It eliminated unnecessary parts on the side, leading to an increase of about 13% in volume compared to conventional sink bowls of similar shape. Representative Director Hong said with confidence, “There are other companies that produce products of 20~25R inner angle. However, only our products have a depth of 215mm or more at the same inner angle.”

Why are wide and deep sink bowls preferred? The first reason that comes to mind would be that if sink bowls are wide, it becomes easier to wash large amounts of dishes, or that if the sink bowls are deep, less water will splatter on clothes or floors. However, Representative Director Hong mentioned something unexpected, “eco-friendliness”. Hong said, “The wider the sink bowl, the less water it requires. If the volume increases, you can finish washing dishes at once, which otherwise needs to be done twice. In that sense, I can say with confidence that LIVING KITCHEN’s INNOVILT sink bowl is a resource-efficient product.”

Another question arose. Wouldn’t it be easy to make a sink bowl with an internal angle of 90 degrees to the desired depth and size by welding the steel plate? Why were the products produced using a one-touch mold method rather than welding? Hong replied, “Producing square welding sink bowls is pricey because it requires a lot of manual work during welding. Mass production is also difficult. Besides, the weld parts portray scales and stains well, so even though the size and depth can be freely controlled, mass-producing welding sink bowls are difficult.”

LIVING KITCHEN is striving to secure sustainable production by adopting a one-touch mold method instead of a welding method, which causes greenhouse gas emissions. With the one-touch method, the company could reduce processing stages and increase productivity, thereby reducing carbon dioxide emissions from equipment use.

l INNOVILT Sink Bowls: How Are They Made?

Now for the highlight of the INNOVILT Alliance trip — taking a look at the production process. As we arrived at the factory, we found that the scene looked quite different from the previous INNOVILT Alliance trips. It was the first time to see so many employees in the factory and robotic arms moving as if they were one. POSCO’s STS304 coils for sinks stacked at the entrance were transformed into sink bowls with a human touch in each process, starting with uncoiling and flattening out the coil, shaping the product with a mold, trimming, washing, and packaging. Something impressive was noticed. After each step of the process, the employees rotated the product around and inspected the quality thoroughly. We didn’t guess so much effort was put into making a sink bowl! See the video below to see the manufacturing process of the INNOVILT sink bowl.

The manufactured sink bowl is then delivered in large quantities to construction companies or sold in the wholesale and retail markets. Although in small proportion, it is also exported overseas. In the case of the INNOVILT sink bowl Quadra and Jumbo series, it has successfully landed contracts of about 120,000 households annually with major companies.

l The Stability of Becoming An INNOVILT Alliance

▲ The INNOVILT Alliance mark placed on the wall of LIVING KITCHEN CO., LTD.

The INNOVILT Alliance mark was placed on the sidewall of the office. As we were taking a picture of it, Representative Director Sung-Wook Hong smiled, saying, “We even had a ceremony to hang this a while ago.” This made sense because we had visited the company less than two months after being selected as an INNOVILT alliance. Hong added, “LIVING KITCHEN Quadra and Jumbo series products are certified by POSCO and are made of POSCO materials, so we can do business with more confidence. We can better persuade clients to trust and use our products. I believe that the INNOVILT certification will not only enhance the trust of clients but also increase the confidence of our employees in the front line of development, production, and sales.”

POSCO’s In-Sik Lee also said, “I am very pleased to hear that the INNOVILT Alliance is also a merit to customers using our materials. Together as an INNOVILT Alliance, POSCO will utilize its infrastructure to provide sufficient business assistance so that we can share growth.”