Here is a person who has a great interest in both steel and the environment. His name is Mr. Greenie Kang. Another person here is Greenie’s friend, Mr. Steely Kim. He is a POSCO employee as well as a steel expert.

Greenie is looking into a TV. As he explores the steel used to make TV parts with a magnifying glass, he finds a tiny nut! He becomes curious about how such hardened steel was cut to make such a fine detailed nut. On searching online, he learns that ‘free-cutting steel’ was used to make these small nuts of the TV. Another thing. He learns that these free-cutting steel contain ‘lead.’ Lead is known to be harmful to the environment, as well as the human body. Is this okay? Greenie meets his friend Steely to find a solution to this issue.

l TVs & Automotives — Various Nuts Used Around Us Contain ‘Lead’?

Have you seen these tiny nuts used to assemble TV parts? I saw one up close, and it had tiny little curves engraved on them! I was wondering how this solid steel was cut, and I found out that it was made with special steel called “lead-based free-cutting steel.” Does this mean that it contains lead, which is harmful to the environment? What is this lead-based free-cutting steel?

Calm down, Greenie. I’ll explain it all for you. First, let me tell you about what free-cutting steel is. It’s not something you’ve heard every day, right? Free-cutting steel is a kind of wire rod product that is specially designed to be machined by precise cutting work. It’ll be easy to understand if you think of it as a wire or spring. To improve machinability, free-cutting steel is made by adding sulfur, lead, and phosphorus. The principle applied here is this: the force exerted by cutting tools, such as knives, is concentrated on the added components of the cutting-steel, causing cracks and facilitating machinability.

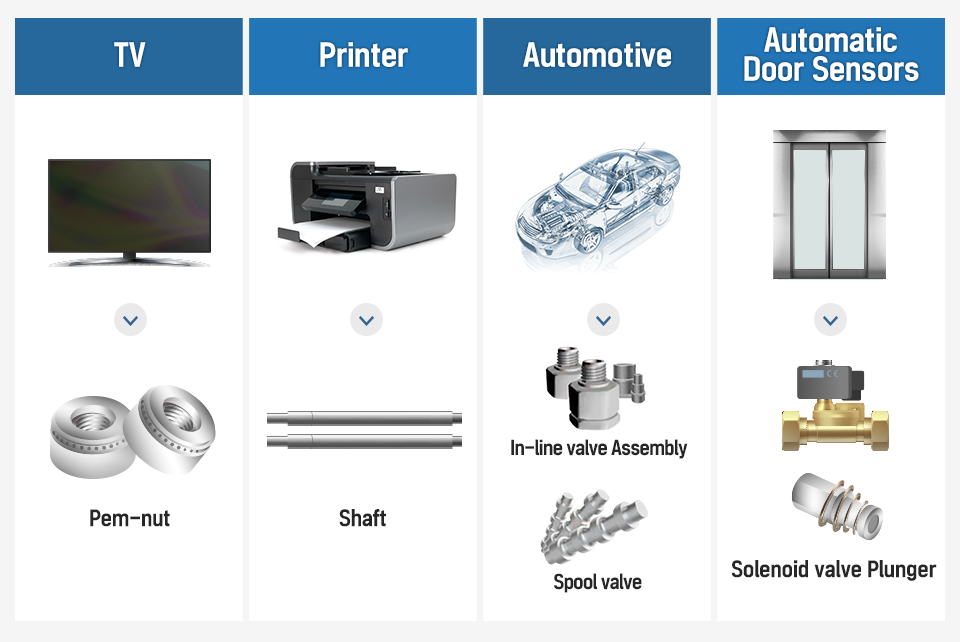

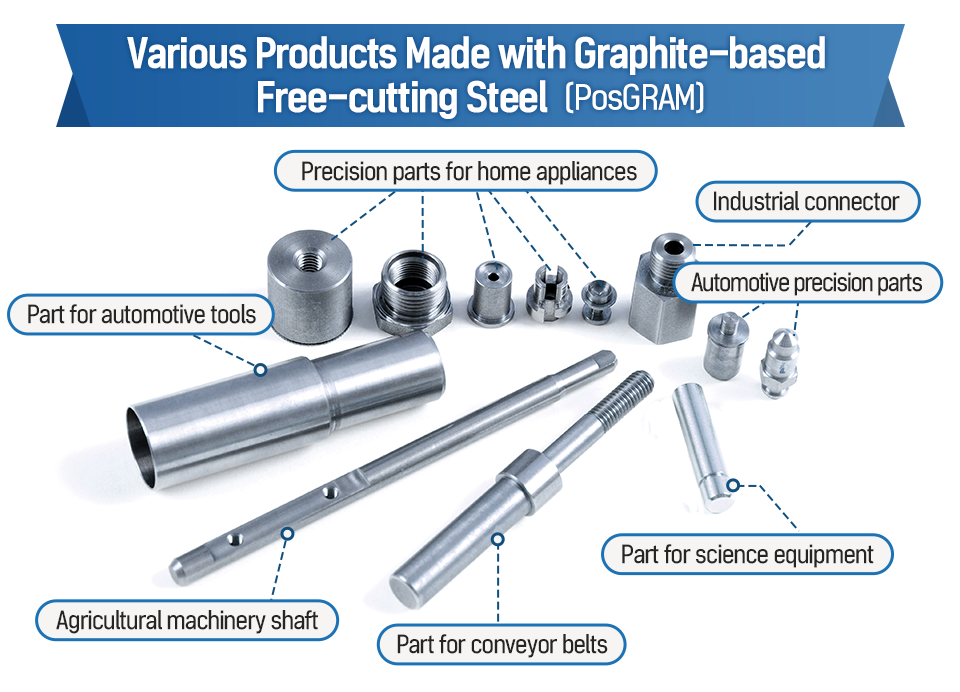

Free-cutting steel is an important steel material, mainly used for fabricating precision parts for electric, electronic, and OA equipment. TV, printer, and automotive parts that we see around us are also made with it. Free-cutting steel is categorized into several types, depending on the added component, and lead-based free-cutting steel is the type mostly used to make ultra-precision parts due to its outstanding machinability.

▲ Free-cutting steel is used in various products around us

However, lead-based free-cutting steel contains lead components that are harmful to the human body. Supposing that lead accumulates in the body, it can cause fatal health issues like inflammation and damages to the nerve system, right? On measuring how much lead was emitted while processing lead-based free-cutting steel, it was found that large amounts were detected in the air, though not visible to the naked eye. In addition, lead-based free-cutting steel causes environmental pollution, since harmful lead components are exposed during the recycling and disposal of products that have free-cutting steel. South Korea imports all lead-based free-cutting steel. Around 23,000 tons are imported annually.

l No Need to Worry! Meet POSCO’s Graphite-based Free-cutting Steel, PosGRAM!

So, lead-based free-cutting steel pollutes the environment and even threatens the health of workers. Then why do they use it?

As the harmfulness of lead-based free-cutting steel became known, its use is decreasing worldwide. However, the problem is that there isn’t any other type of free-cutting steel with good machinability to replace it. So, even RoHS and ELV regulations, which are international guidelines for restricting hazardous substances, set aside exceptions for lead content in the case of steel alloys. RoHS and ELV limit the amount of lead in products to 0.1%. However, in the case of lead-based free-cutting steel, which has no alternative, the standards allow up to 0.35%.

* ELV (End of Life Vehicle): A directive of the EU addressing the end of life for automotive products.

sss

So, you mean there are products that contain up to 0.35% of lead around us?

Unfortunately, that is the case for now. Many global steelmakers have tried to develop free-cutting steel that is lead-free, but it was in vain to come up with an alternative that has both excellent machinability and price competitiveness against lead-based free-cutting steel. POSCO has also been focusing on developing steel that can replace it. R&D period alone took three years. At last, POSCO researchers found an alternative substance that has no toxic ingredients while maintaining the excellent processing properties. It is none other than graphite! Last year, POSCO succeeded in developing and mass-producing graphite-based free-cutting steel for the first time in the world. This new product is named PosGRAM(Pos GRAphitic steel for Machinability). To create graphite-based free-cutting steel, fine graphite is distributed within the steel, enabling it to be utilized as free-cutting steel.

sss

Graphite? Is it something like charcoal?

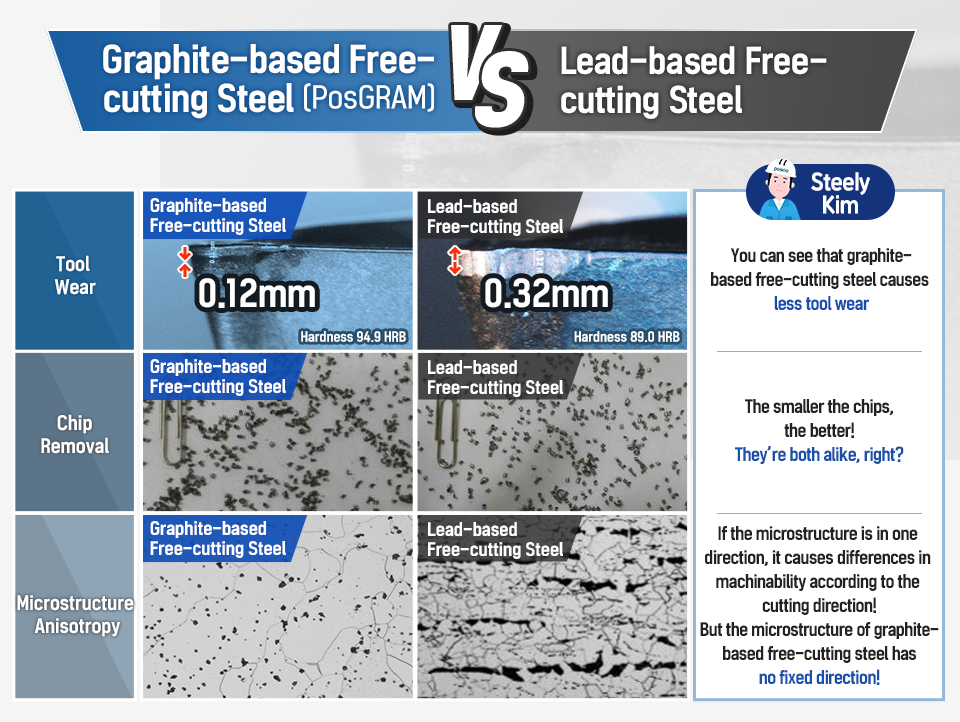

An example of graphite that you can easily see would be a mechanical pencil lead. Graphite is a mineral made of pure carbon. The binding structure between the carbon layers is weak, so it is easy to cut through — just like mechanical pencil lead breaks easily. In addition to its excellent machinability, graphite also acts as a lubricant between the tool and the chip, thus reducing friction. In other words, graphite-based free-cutting steel reduces tool wear. Also, it displays similar chip removal when compared to lead-based free-cutting steel. Since graphite-based free-cutting steel has no microstructure anisotropy, there is no difference in machinability — no matter in which direction it is cut.

An example of graphite that you can easily see would be a mechanical pencil lead. Graphite is a mineral made of pure carbon. The binding structure between the carbon layers is weak, so it is easy to cut through — just like mechanical pencil lead breaks easily. In addition to its excellent machinability, graphite also acts as a lubricant between the tool and the chip, thus reducing friction. In other words, graphite-based free-cutting steel reduces tool wear. Also, it displays similar chip removal when compared to lead-based free-cutting steel. Since graphite-based free-cutting steel has no microstructure anisotropy, there is no difference in machinability — no matter in which direction it is cut.

▲ Graphite-based free-cutting steel, PosGRAM, shows at least equivalent or superior performance in terms of tool wear and chip removal compared to lead-based free-cutting steel! Besides, it shows no difference in machinability in any direction, because it has no microstructure anisotropy.

l No More Lead-based Free-cutting Steel, Right?

I’m really glad that POSCO developed PosGRAM. Now we don’t have to worry about environmental pollution caused by lead-based free-cutting steel anymore!

That’s right. POSCO has opened a new chapter in global Sustainable material technology by successfully developing PosGRAM to replace lead-based free-cutting steel! As of now, the use of lead, a harmful element, is being regulated in many countries around the world. So, global precision parts manufacturers and automotive companies are trying to stop utilizing parts that contain hazardous substances such as lead. POSCO’s solution, which keeps pace with this flow, is expected to be of great help in protecting our planet from lead poisoning.

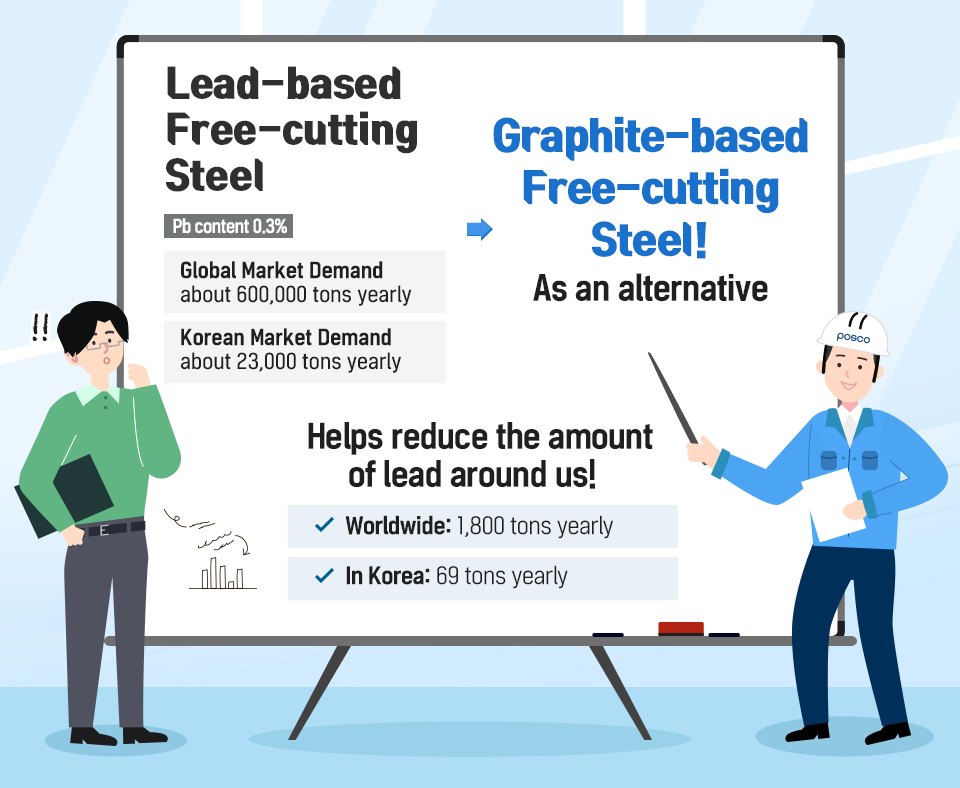

The annual global market demand for free-cutting steel is estimated to be 1 million tons, among which 600,000 tons are for lead-based free-cutting steel. There is no domestic manufacturer in Korea, so over 23,000 tons of lead-based free-cutting steel are imported annually from overseas. The average amount of lead in it is 0.3%. Assuming that all existing lead-based free-cutting steel is replaced with PosGRAM, the use of harmful lead is expected to be reduced by 1,800 tons per year (69 tons in Korea).

Since this PosGRAM was developed by POSCO, it may assist in strengthening the industrial competitiveness of Korea as well.

sss

So, will the lead-based free-cutting steel around us disappear for good?

Now that PosGRAM has been developed, it has to be applied to the market successfully. That is why POSCO has been actively engaging in marketing activities to enable the new product to quickly replace the existing lead-based free-cutting steel in Korea. Aiming to eliminate the use of old ones in Korea within the next five years, POSCO is offering various solutions to its customers, who have been utilizing lead-based free-cutting steel only, so that they can adopt PosGRAM. POSCO is also pursuing to obtain PosGRAM’s certification from end-customers.

For example, to SeAH Special Steel, the largest manufacturer of free-cutting steel products in Korea, POSCO has provided the technology that enables the utilization of PosGRAM instead of lead-based free-cutting steel. And both companies have jointly conducted processing evaluation as well. POSCO and SeAH Special Steel are also carrying out various certification processes together, starting with industrial products to expand the use of PosGRAM gradually into the home appliances and automotive markets.

Once POSCO’s PosGRAM successfully settles in the market, there’s no need to worry about lead being used in cars, home appliances, and OA equipment that we see around us. Workers will also be safe since they aren’t exposed to lead. PosGRAM doesn’t cause any water pollution or soil contamination on being recycled or disposed of, so PosGRAM is a way to “save the environment and protect the health of people.”

Greenie was quite worried about the harmful lead-based free-cutting steel at first, but now he looks quite satisfied hearing the news of POSCO’s PosGRAM. POSCO isn’t just a world-class steelmaker — it actively participates in resolving environmental issues with its excellent steel solutions. Even today, POSCO is on its way towards making Earth safer