Manufacturing has long been an industry run by traditional practices of mass production, but with changing times, smarter systems are becoming a necessity.

This is where POSCO’s Smart Factory comes in. As a leading steelmaker, POSCO prides itself as being one of the most innovative manufacturing companies in the world, and by incorporating cutting-edge technology in its day-to-day operations, it’s easy to see how this is possible.

How Does It All Work?

The Smart Factory is all-encompassing: not only does this system cover the actual machinery of POSCO’s steel manufacturing through the IoT and artificial intelligence, but also highly-tuned wearables that ensure workplace safety.

Smart technology is not something new to POSCO, as it has embraced the IoT to create safer workplaces in the past.

The Smart Factory takes POSCO’s already-firm hold over smart manufacturing technology, and applies it to a broader purpose. Enhancing facilities by making them smarter not only helps workers, but improves the product overall.

Now, how exactly does this Smart Factory work, and what does it really do?

Starting with the Basics: Operation Management

Steel manufacturing facilities are large and complex, and in order to create the best product, the major units need to be properly managed.

One example is the monitoring of a rolling mill. POSCO’s Smart Factory houses rolling mills with IoT sensors attached, which collect data for analysis. These pieces of equipment are crucial to the steelmaking process – they take semi-finished slabs and flatten and elongate them.

The Smart Factory analyzes the data, and automatically sends out directions to control settings for an optimized operating environment. Whenever the sensors detect abnormal signals, operators can zoom in on inspecting its whereabouts.

If there is a case where external support is needed, the Smart Factory takes into account the skills of the workers on site, and evaluates what is needed. 3D blueprints examine facilities for enhanced efficiency, using virtual simulation to study the facility from the inside-out.

Guaranteeing Quality Control

One of the reasons why POSCO is considered a premium steel producer is because of the quality of its products. Hence, it is crucial that its facilities are able to perform to the best standards possible.

With the Smart Factory, POSCO is able to identify any defects during the production process prior to the final stages of the operation.

The system carefully examines each product from start to finish, monitoring raw materials from initialization to checking the state of a nearly-finished product entering a blast furnace.

In the chance that a defect does manifest, the Smart Factory scans the products to diagnose the problem. As a program meant to learn, the operation determines the exact cause of the defect, taking into account how to prevent it from occurring again in the future.

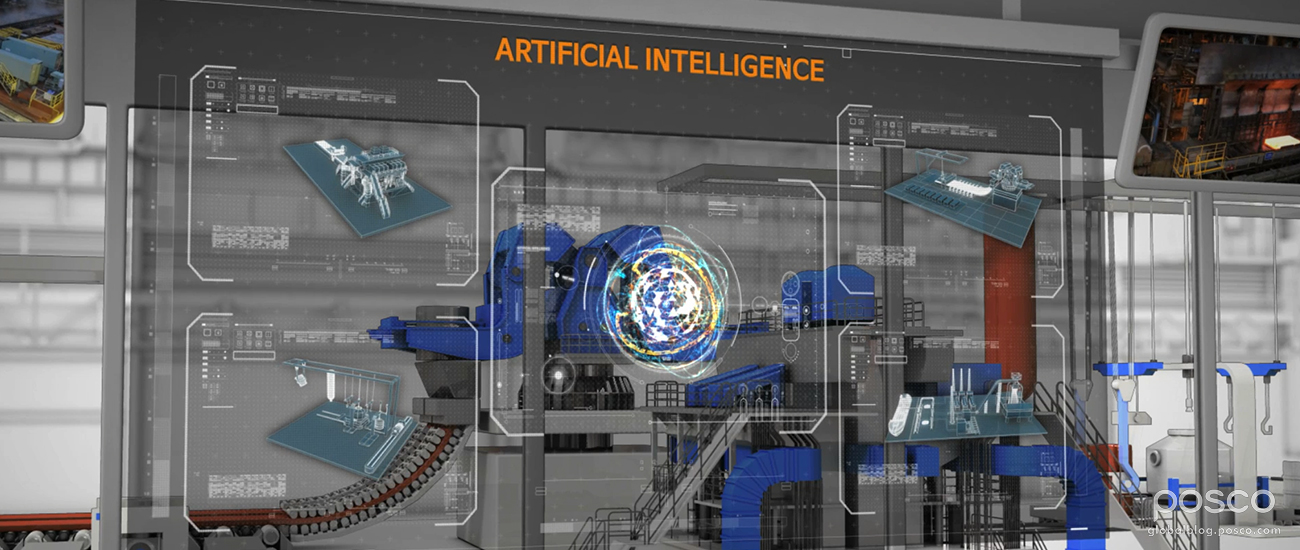

Enhanced Support from Artificial Intelligence (AI)

The most interesting ingredient in POSCO’s Smart Factory is artificial intelligence (AI) – which is utilized to create an optimized environment without human interference.

AI allows the facility to be able to conduct inspections throughout the facility, independently assessing issues and automatically assigning solutions given the available information. It is one of the elements that contribute to the unique nature of the Smart Factory.

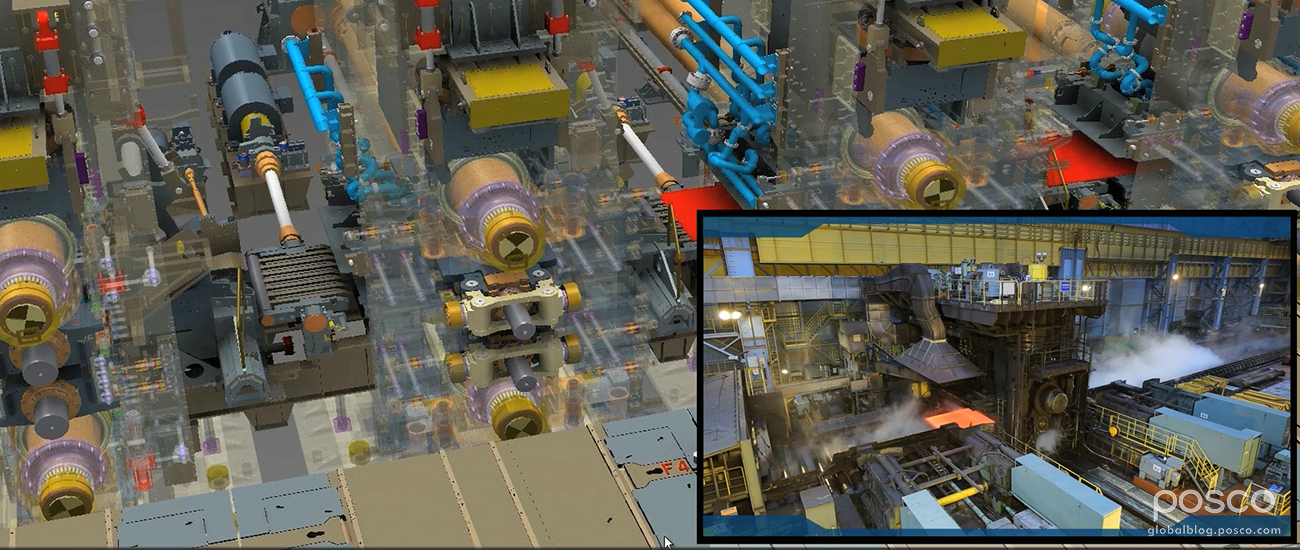

Predicting through Simulation

The Virtual Factory is a 3D virtual facility that is a replication of the actual factory environment, simulating the production process and predicting the quality of new products.

With this technology, POSCO established a system that would create new, high-quality products in a shorter period of time.

The Virtual Factory also serves as a source for new employees to learn how to operate facilities, minimizing the chance for errors.

Prioritizing Employee Safety

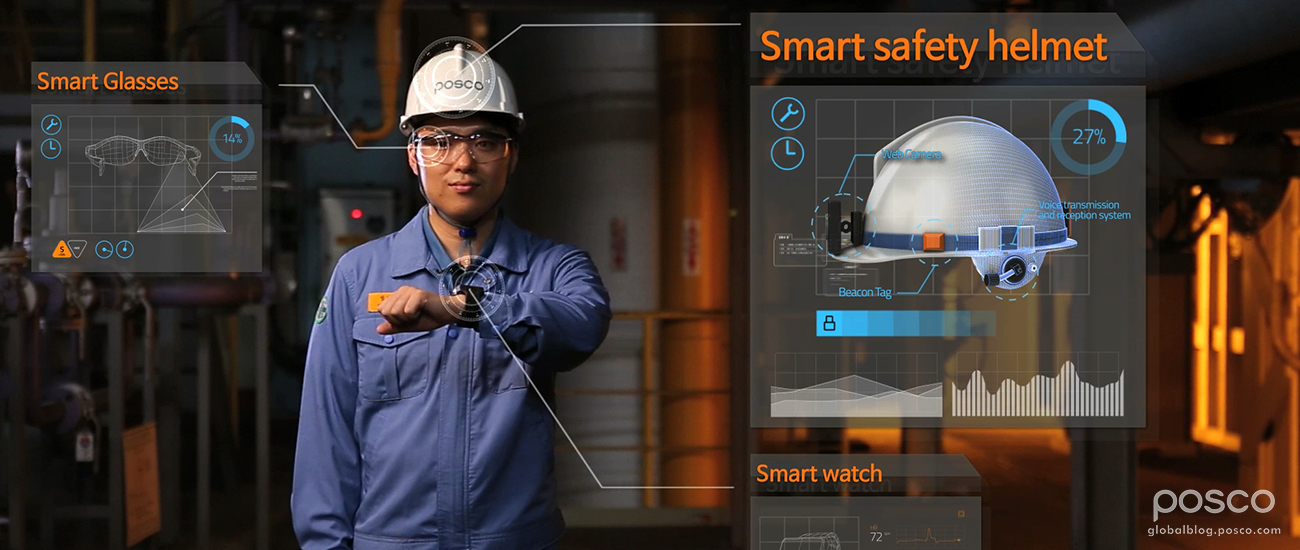

Last, but definitely not least, POSCO’s Smart Factory model incorporates managing employee safety in smarter ways.

Sensors are installed in the workplace to pick up on any harmful stray gases, noises and temperatures, and notify operators of threats. They also look out for people working on site, monitoring and alerting employees in situations where they might be close to hazardous objects.

Wearables have been used for safety purposes in the past at POSCO, and with the addition of Smart Bands, workers working in harmful environments will be able to better prevent injuries. Data from the band is sent to a control center for immediate action in case of trouble.

Smart Factory, Smart Company

POSCO has already involved the IoT to develop improved safety measures, but now with the Smart Factory, the entire production process has advanced for the sake of creating better products in the future.

The Smart Factory transforms the conventional idea of a steel mill into an intuitive operating system, promising faster production, higher-quality goods and safer work environments.

Matching its position as a leading global steelmaker, POSCO’s Smart Factory gives evidence of the company’s optimized facilities for creating the most reliable steel products available worldwide.

POSCO Looks to Internet of Things (IoT) for a Safer Workplace