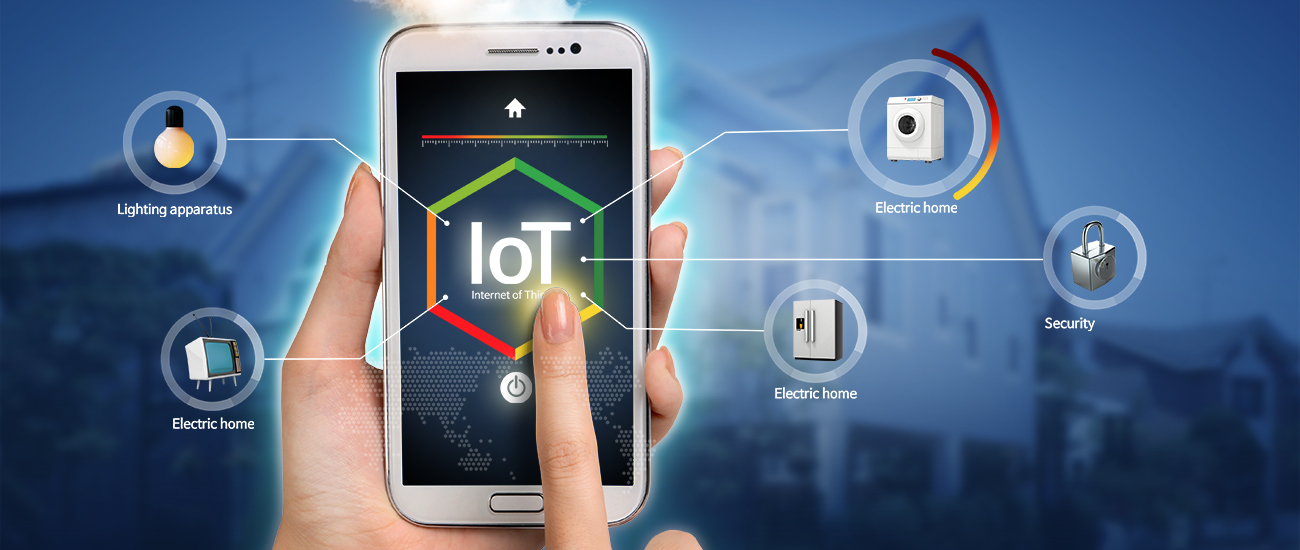

In this technological age, the latest and biggest development is the rise of the Internet of Things (IoT). Sensors, software and technology are being embedded into everyday objects, clothes and devices, and networked so that they can exchange information, become intelligent and transform our lives.

Smart Cities automatically detect cars, adjusting traffic lights to optimize flow. Smart Homes know when to turn the lights on and off or when to order more groceries. And Smart Devices track people’s movements, their biorhythms and more, so people can better take care of their health.

The Internet of Things (IoT) can also be elegantly simple. For example, Amazon has launched the innovative Amazon Dash, a simple, Wi-Fi-enabled button that can be attached to items around the home, and with a press it orders more of that item. Amazon Dash can be used to order paper towels, diapers, laundry detergent and other commonly used consumer products, connecting your home, making it smarter, and adding a new kind of convenience.

The Internet of Things (IoT) has come to POSCO, too, particularly when it comes to safety. As part of an approach to developing solutions called POSCO’s “Smart Safety,” POSCO is using the Internet of Things to improve safety awareness, reduce risks and get all our employees invested in being actively involved in safety.

POSCO’s Smart Safety Case Studies: Wearables to Ensure Safety

The current focus for improving safety in the workplace focuses on removing risks and raising awareness, to change people’s habits and sense of ownership. By combining these activities with the IoT, POSCO is looking to provide more scientific and efficient solutions.

Two case studies highlight the potential power of POSCO’s Smart Safety approach. One is using Internet of Things (IoT) technology to protect against gas leaks in factories. To guard against dangerous gases, POSCO uses sensors, constantly checking the air to make sure it is not poisonous or suffocating.

By connecting these sensors to employees’ smart watches, POSCO is able to increase the intelligence and speed of these safety networks. When a sensor detects a dangerous gas, it can immediately connect to everyone’s wearable devices, so they can instantly learn there is a problem and quickly get clear of the danger zone.

In addition, by analyzing information about the gas leak, the factory safety systems can automatically determine where the leak is originating and block the valves around it.

For the second case study, POSCO proposed adding additional sensors and safety equipment to employees’ clothing, giving them additional IoT protection even when working alone. In the hard hat, an accelerometer and other sensors could be added to monitor each person and protect against falls, gases and other dangers. In the safety vest, biosensors monitor heart rate, body temperature and other personal conditions. And a GPS sensor in the safety vest could ensure the company knows where its employees are, to better ensure their safety during an emergency.

By making our employees’ clothes into smart clothes, we can greatly increase awareness of and responsiveness to potential problems, which means reducing risk and keeping all workers safer.

Using Competition to Get Everyone Involved in Safety

POSCO has also worked to get everyone more involved in promoting safety through a Smart Safety Idea Competition. The entire company participated in this contest, held from March 21 to April 10, with 1,072 ideas officially submitted.

Among the ideas about how to incorporate IoT technology to improve safety were using location-based services to monitor workers in the factory; risk-monitoring on large vehicles like cranes and handling equipment; wearable devices to monitor worker health; and using aerial drones to monitor for gas leaks.

Employees’ strongest ideas will be picked, judged on effectiveness, realism, economics and related criteria. The winners of the safety competition will be announced in June.

Embracing Technology to Always Put Safety First

POSCO has long been an innovator in the steel industry, always looking to use the latest technology to create the best-possible products. And it’s no different when it comes to safety—any and all tools are welcome if they can help make the POSCO workplaces better for our employees.

The Internet of Things is transforming our world, making all sorts of everyday objects smarter and more connected, and that’s an innovation that can make a real difference in the steel industry. By being at the forefront of implementing the latest technology into a new safety paradigm, POSCO is showing its dedication to becoming “POSCO the Great.”