STEEL Talk presents to you interesting stories of Science, Technology, Energy, Environment, Life — and of course STEEL!

Today’s question is about the English saying, “Strike while the iron is hot.” The child who sent this question wants to know why we should strike iron. Let’s explore the science behind this saying with POSCO Newsroom.

First of all, let’s take a look at the process of how a blacksmith works to explain the reason why we should strike the iron while it’s hot. Have you seen blacksmiths on TV before? A blacksmith is a craftsman who makes tools and equipment by heating and hammering metals such as iron, copper, and tin. Sickles used for farming, as well as horse hooves and knives, were all born thanks to blacksmiths.

| Why Do Blacksmiths Heat the Iron?

Blacksmiths put solid hard iron into a forge and heat it at a temperature high enough to soften it. After the heated iron turns red, It is then pulled out with tongs and hammered to form a shape. The most important thing here is the timing.

If you miss the timing and the iron cools down, shaping it becomes hard — no matter how hard you strike it. This hints the meaning hidden behind the saying, “Strike while the iron is hot.” To shape iron, you should work on it soon after it’s molten. Because if you don’t, the iron will turn solid hard as before, and changing its shape then would be impossible. Putting that into consideration, the message of the saying would be this. “There is a timing for everything, so you shouldn’t put off things that need to be done now, for later.”

| Even In POSCO Steelworks Today, “Strike It While It’s Hot!”

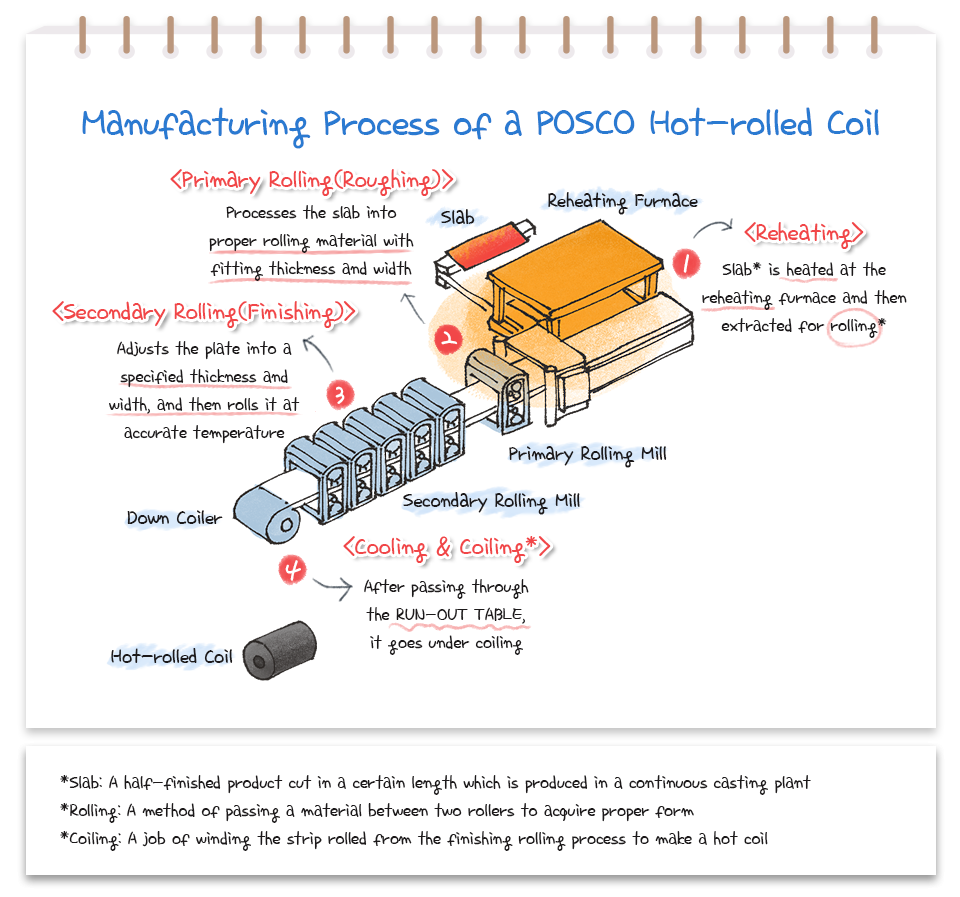

The method of blacksmiths in the past is also applied to the steelworks of today. Molten iron from the furnace is first molded into a cube-shaped half-finished product (slab) and left to cool down. This slab goes into a reheating furnace when making a product. It’s just like how blacksmiths worked with their forge. Next, the reheated slab passes through the rolling mill and is winded into thin rolls, resulting in the end-product — a hot-rolled coil. The manufacturing process below will help you understand better.

The blacksmiths’ way of working in the past is re-enacted in the steelworks of today, through state-of-the-art technology and fully automatic facility. POSCO’s steelworks have evolved even further with AI technology. Through AI, knowing exactly when the iron should be heated or cooled off, and when it should be hammered or compressed, became possible. This enables the manufacture of high-quality and high-performance products that meet the needs of clients.

There are various sayings of different cultures that refer to iron and steel — like the Korean saying, “Iron gets stronger, the more it is struck on”, the American saying, “The Finest steel has to go through the hottest fire”, and the Chinese saying, “Out of the hottest fire comes the strongest steel”. As can be seen here, most of the sayings that are related to iron imply that harsh, extreme conditions and hardships enable growth. Perhaps this is why steelmaker POSCO has such a fierce and strong image.

Now you know the story behind the use of ‘iron’ and ‘steel’ in sayings. Isn’t it quite interesting? POSCO Newsroom hopes everyone who is going through a difficult time would not lose hope but go on, overcome, and become stronger — just like the sayings we saw today! Please feel free to ask POSCO Newsroom if you have any other questions!