Decarbonization of steel is emerging as an inevitable challenge

Countries worldwide are working toward a low-carbon economy by setting ambitious targets to cut greenhouse gas (GHG) emissions to achieve carbon neutrality. Moreover, with the notice of the European Union’s forthcoming implementation of a carbon border tax, carbon neutrality in industries with high carbon intensity can no longer be deferred. In particular, steel is a typical carbon-intensive product that involves an iron ore reaction with coal as fuel and coke as a reducing agent and produces significant carbon emissions during manufacturing. POSCO, a leading steel company, declared 2050 Carbon Neutrality on December 11, 2020, and plans a comprehensive infrastructure reorganization to achieve decarbonization with eco-friendly raw materials, carbon capture and recycling, and hydrogen reduction steelmaking.

▲ POSCO Group officials at the launch event for Greenate, the company’s eco-friendly master brand

Launch of Greenate, an integrated initiative brand

POSCO is taking steps as Korea’s leader in carbon neutrality by actively participating in technology, product innovation and social efforts to reduce carbon emissions. In November 2022, POSCO launched the carbon-neutral master brand Greenate at the Green Materials Forum 2022 held to strengthen future business with customers. The brand name is a compound word of “Green,” which represents POSCO’s commitment to the environment, and “-ate,” a suffix that means acting in a certain way, and expresses POSCO’s intention to create a “green planet.” POSCO launched Greenate because of the need to integrate its efforts and outcomes to achieve carbon neutrality and communicate them intuitively.

POSCO’s flagship eco-friendly brand Greenate consists of three categories: Steel, Tech & Process, and Infrastructure, and covers not only POSCO’s eco-friendly steel products led by e Autopos, INNOVILT, and Greenable, but also low-carbon steel technology and processes, especially next-generation hydrogen reduction iron and steel making.

Introduction of sub-brands: ① Steel, ② Tech & Process, and ③ Infrastructure

First, Greenate Steel refers to products that contribute to reducing carbon footprints throughout the life cycle assessment (LCA) from steel production to use and disposal. It is divided into footprint minimization and handprint enhancement products.

1. Footprint minimization products: They include steel produced using recycled raw materials, such as scrap, to reduce carbon emission during steel production and by applying carbon-reducing manufacturing technology such as using new & renewable energy power and applying low-carbon fuel and raw materials.

2. Handprint enhancement products: They are steel materials that contribute to reducing carbon footprint from a customer’s use cycle perspective, such as the use and disposal of steel and include steel materials that replace competitive materials, such as aluminum and cement, that emit much carbon in product processes compared to steel materials, along with those that are applied to low-carbon industrial use, such as wind power, solar power, and hydrogen, and those such as high-tensile automotive steel plates that contribute to improving automobile fuel efficiency.

Greenate Tech & Process includes low-carbon steel technology and processes. POSCO plans to reduce the amount of coal and energy used in processes by introducing electric furnaces, using hot briquette iron (HBI) for facilities currently in operation, and developing bridge technologies such as low-HMR operation/CCUS technology. In the case of hydrogen reduction iron and steelmaking process technology, POSCO plans to verify the feasibility of commercializing HyRex technology based on FINEX fluidized reduction furnace technology by 2030 to break away from conventional blast furnace steel making that emits carbon by reacting coal with iron ore.

Greenate Infrastructure establishes all necessary conditions for the realization of Greenate Steel and Greenate Tech & Process. POSCO plans to establish a hydrogen production and supply system for the hydrogen reduction iron and steelmaking technology and achieve carbon neutrality with an eco-friendly power infrastructure. POSCO, hosted the world’s first Hydrogen Iron & Steel Making Forum (HyIS Forum) in 2021, updates the progress of global hydrogen reduction iron and steel initiatives and discusses measures to reduce GHG at the forum each year. The company also collaborates with various companies on raw materials, steel, and equipment technology through the HyRex R&D Partnership exchange platform. POSCO plans to continue to expand various activities aimed at carbon reduction.

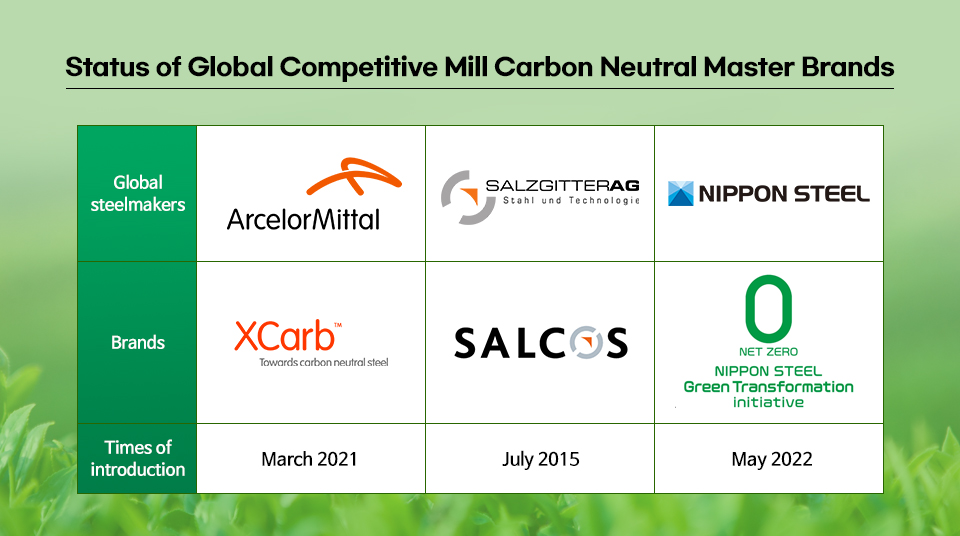

Operational status of global competitors’ low-carbon brands

Global steel companies also operate master brands that include steel technology projects to achieve carbon neutrality.

ArcelorMittal announced the XCarb Initiative, a green innovation project to build a next-generation circular economy and demonstrate carbon-neutral steel. The company introduced the XCarb Green Steel Certificate to help its customers reduce their carbon footprint. Another steel maker, Salzgitter AG, plans to dramatically reduce carbon emissions during steel production based on its conversion program SALCOS (SALzgitter Low CO₂ Steelmaking). The company is testing carbon-free steel manufacturing processes to realize green hydrogen production. Nippon Steel announced that it will sell carbon-neutral steel with zero CO2 emissions starting this year. Its decarbonization strategy includes using green electricity, developing high-performance products, such as advanced ultra-high-strength steel (AHSS) to reduce vehicle weight and high-performance steel for EV drive motors, and increasing supply capacity.

POSCO Launches Korea’s First Low-Carbon Brand Product

One of the notable products introduced by POSCO is “Greenate certified steelTM,” which operates on a mass-balance principle. This product effectively reduces carbon emissions by distributing the emissions saved through the implementation of low-carbon production processes and the use of low-carbon steel. Companies that purchase this product are acknowledged for their efforts in reducing carbon emissions equivalent to the amount associated with the product.

At the Green Materials Forum 2022 on November 1 last year, POSCO Group launched Greenate, a master brand representing the company’s ambitious mission to achieve carbon neutrality by 2050, after which the product is named. Greenate encompasses all the efforts and products of POSCO Group to produce low-carbon steel and eco-friendly secondary battery materials, as well as the three major eco-friendly steel brands e Autopos, INNOVILT, and Greenable.

Leading steel manufacturers in Europe and Japan had already adopted the mass balance methodology, which involves allocating carbon reductions to specific steel products, in 2021. POSCO became the first company in Korea to adopt this method for launching a low-emission product.

The evaluation of carbon emission reduction for Greenate was conducted according to the GHG Protocol, a widely used international standard that measures greenhouse gas emissions. The assessment was performed by DNV (Det Norske Veritas) UK, one of the top three certification agencies globally, with extensive experience in certifying carbon-reduced steel from steel companies worldwide. The evaluation took place at POSCO’s Pohang Works and Gwangyang Works.

Companies that purchase Greenate certified steelTM receive DNV’s product guarantee, with includes information on carbon reduction information on the raw material, along with POSCO’s purchase certificate.

▲ Eom Gi-cheon, head of POSCO’s Marketing Strategy Office, invited customers to the POSCO Center on June 1st to explain POSCO’s plan to release reduced Low-Carbon Brand products.

“The low emission trend is inevitable in the steel industry, and POSCO is responding proactively by launching new products,” Gi-cheon Eom, Head of Marketing Strategy Office, said at the briefing session. “With the launch of Greenate certified steelTM, the company has taken a step forward in its long journey towards carbon neutrality.”

LG Electronics is the first client to purchase the newly released Greenate certified steelTM. Last November, POSCO and LG Electronics signed a business agreement for the supply and purchase of mass-balance type low-carbon steel products. Immediately after the product launch, LG Electronics placed an order for 200 tons of the new steel, which will be used as materials for their dryers. The company intends to actively explore opportunities for expanding the use of low-carbon steel in household appliances in the future.

In addition, Samsung Electronics is currently considering the procurement of Greenate certified steelTM for their premium ovens. Recently, POSCO and Samsung Electronics entered into a three-year supply contract for high-strength, high-corrosion, and electric steel plate products for home appliances. This marks the first long-term agreement between the two companies, underscoring their shared dedication to technological collaboration and carbon neutrality.

POSCO actively invests in the transformation to climate-friendly production, even in the high-energy era

POSCO Group launched the holding company POSCO Holdings in March of last year and announced its aspiration to grow into a leading eco-friendly future materials company by gradually shifting to a carbon-neutral production system and proactively establishing eco-friendly infrastructure to achieve its 2050 carbon neutrality goal. As POSCO Greenate won the grand prize in each category in the Korea Consumer Appraisal Brand (KCAB) hosted by The Dong-A Ilbo in February, the Group is expected to solidify its global competitiveness in the low-carbon era with continuous innovation in eco-friendly steel products, production technology and solutions using products.

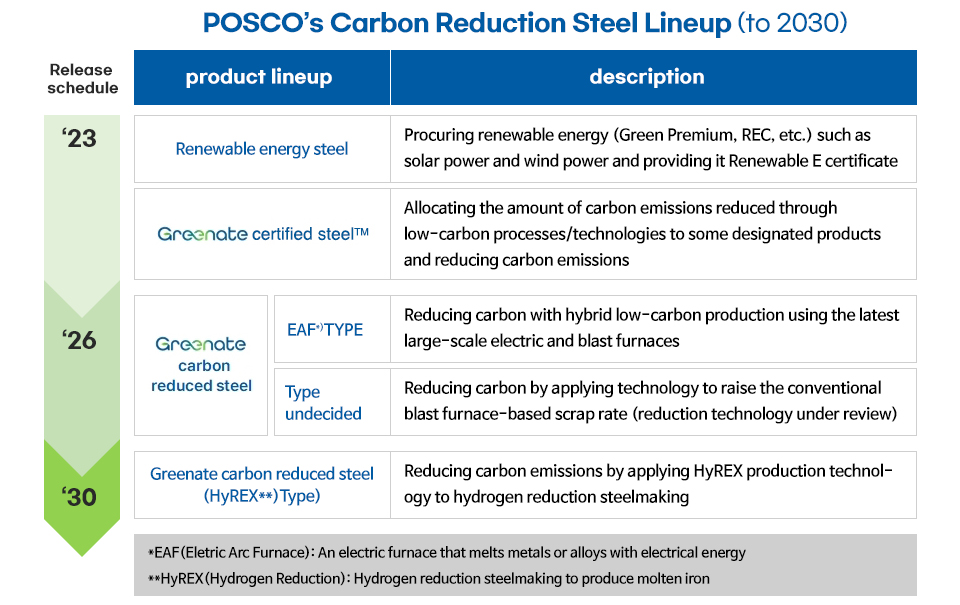

POSCO plans to reduce carbon emissions by improving conventional blast furnace-based low-carbon operation technology and building new electric furnaces that directly produce molten steel or mix it with molten steel produced by blast furnaces beginning in 2026. Moreover, after completing a test facility for hydrogen reduction steelmaking in 2026, the company plans to complete commercialization technology by 2030 and gradually convert production facilities to a hydrogen reduction steelmaking method.

In line with this, POSCO plans to support the carbon reduction activities of customers by selling renewable energy steel with the purchase of renewable energy credits, etc., and Greenate-Certified SteelTM using a carbon allocation method in the short term until the Gwangyang Steel Plant’s electric furnace is fully operational in 2026, and in the mid- to long-term, it plans to sell Greenate carbon-reduced steel, which reduces carbon emissions by 30% or more through blast furnace-based low-carbon operation, cutting-edge large-scale electric furnaces, and hydrogen reduction steelmaking.