In today’s automotive industry, it is very important for steel manufacturers to stay ahead of their competition in all aspects, including new product development, new material solutions, new technology and so forth.

Many leading global steel companies are forming “supply networks” in order to lock in the benefits of early vendor involvement (EVI).

EVI is a collaborative strategy in which an automotive manufacturer involves a supplier at an early stage of the product development process. Due to the advantage of involving steel suppliers on cross-functional teams of product development, it gives many benefits to the OEM customer and other automotive part suppliers. Some of these benefits include lower production cost, shorter development cycle, lower development cost, etc.

Solution Exchange Visit (SEVIT) is one of the market promotional initiatives that POSCO participates in globally. This year, we conducted the “SEVIT program” in Chennai, India with many OEMs and automotive part suppliers at various locations, like the Mahindra Research Valley, Ashok Leyland Technical Centre, Wheels India Limited, Tube Product India, etc. from November 23 to November 25 of this year. A total of 11 participants from POSCO took part in this program – six representatives from POSCO R&D (including the director), four representatives from POSCO-India TSC and one sales representative from POSCO-ICPC.

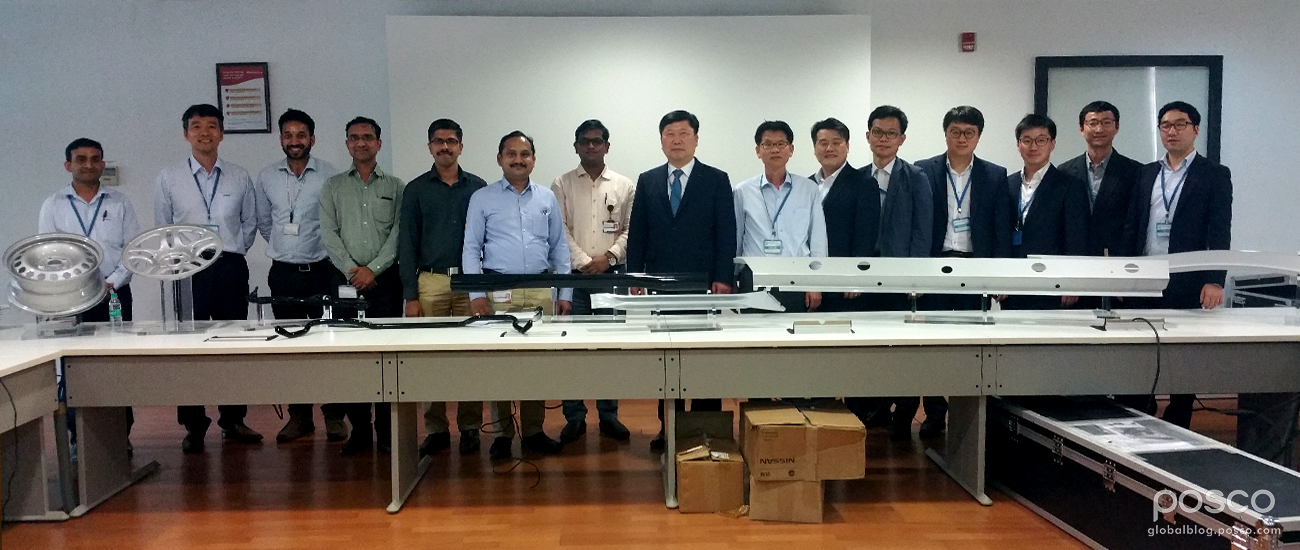

POSCO R&D director Gyosung Kim, a POSCO senior researcher, and POSCO-India TSC staff take a picture with Mahindra & Mahindra research representatives, as participants of the SEVIT program at Mahindra Research Valley.

During this program, POSCO R&D’s director and senior researcher, and other TSC India staff met with many senior leaders of a major OEM.

As many knows, weight reduction of vehicles (without compromising crash resistance), energy efficiency and low emission are the biggest challenges the automotive industry is currently facing. With this interest in mind, POSCO’s R&D team presented various advanced solutions for vehicle weight reduction. It also introduced new technologies such as roll forming, POSCO Body Concept (PBC) for bus frames, first and second generation styled wheels, along with various solutions for welding challenges. POSCO’s team also demonstrated various alternate material solutions, such as PosM Steel 880, 1180CP, 1470 H-P, 1800 H-P, etc., for various automotive structural and chassis parts. Some of the parts included: styled wheel disks, reinforced side sills, door impact beams, CTBAs, stabilizing bars and lower control arms, to replace the existing usage of lower strength material.

(left) A senior researcher from POSCO R&D explains the benefits of using automotive structural and chassis parts manufactured by POSCO, on display, with advanced technology and alternate material solutions. (right) After each presentation, there was an open Q&A session. There was tremendous enthusiasm across participants, who asked many questions and queries, which were then efficiently clarified by the POSCO team.

All Indian OEM customers recognized our initiative and appreciated it as one of the benchmark promotional activities among steel suppliers in the Indian market. As none of our domestic or global competitors are doing this kind of activity in India, the program was very helpful for the growth of business and starting a new project with OEM customers. The SEVIT program turned out to be very successful, with all customers requesting to have another similar program take place in the near future.

POSCO EVI Forum Impresses With Solution Marketing