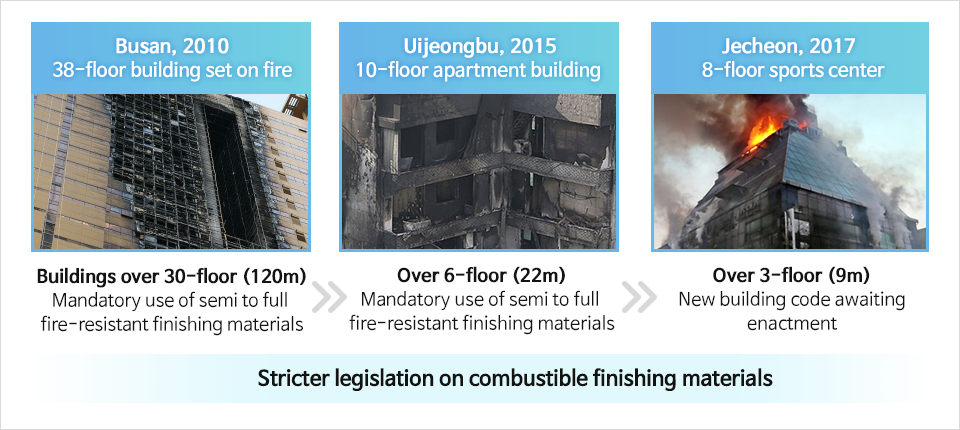

In 2010, a mass fire burns in Busan multi-purpose building triggered an alarm for Korean authorities. What started as a tiny spark on the fourth floor spread all the way to the 38th-floor rooftop in less than 30 minutes. Flammable exterior wall panels were to blame for the quick spread.

After the Busan fire, Korean government banned combustible finishing materials for buildings over 30 stories (120m) to prevent similar mass fires. Despite the new legislation, mass fires continued — even in smaller buildings.

After the devastating hospital fire in Miryang last year, the government is now set to enact new legislation mandating non-combustible finish materials for buildings over 3 stories. For the construction industry, the new law is practically a ban on all combustible materials.

Now, POSCO C&C is addressing the industry and the government concerns with a new innovative product: a non-flammable color steel sheet. POSCO Newsroom reports.

l Hardly Burns, Hardly Fumes

On July 5, POSCO C&C(POSCO Coated & Color Steel Co., Ltd), unveiled the company’s non-combustible color steel for the first time.

Most fire casualties occur when victims inhale smoke or toxic gases – which is what POSCO C&C tried to address when they developed the new non-combustible steel. How did the company develop a new building material that hardly burns and hardly fumes?

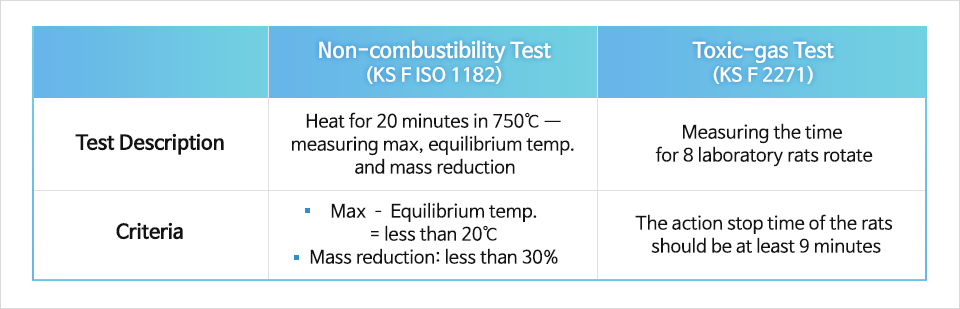

(1) KS F ISO: Non-combustibility Test

POSCO C&C primarily focused on developing a product that meets the KS F ISO criteria, set by the Korea Conformity Laboratories (KCL).

The non-combustibility test measures the burning behavior of a material. Test material is placed into a furnace. The furnace heats the material at 750°C for 20 minutes. The maximum and equilibrium temperatures are measured, as well as the mass reduction of the material.

To meet the KCL standards, the difference between the maximum temperature and the equilibrium temperature should remain below 20°C — and the mass reduction should be 30% or less.

▲ Non-combustibility test conducted by POSCO C&C. The test materials are heated at 750°C for 20 minutes — then the maximum temperature, equilibrium temperature, and mass loss rate are measured. (Image source: POSCO C&C)

Normally, when a test material catches fire, the temperature rises quickly — by over 20℃. For conventional color steel plates, the temperature increase is around 80 ~ 100 ℃. As for POSCO C&C’s non-combustible color steel, the temperature difference between the maximum and the equilibrium levels is within 20°C.

When a material burns, a certain level of mass reduction is expected — the volume reduction signifies the amount of materials burnt. As for color steel, most weight of its weight comes from the steel portion. This means color steel retains most of its mass even in the event of a fire.

<Non-combustibility Test: Criteria>

(2) KS F 2271: Toxic-gas Test

The second criterion POSCO C&C strived to meet was the toxic gas test, KS F 2271. In this test, eight laboratory rats were put in a rotating wheel measuring how long they can rotate until they stopped — this time is defined as ‘action stop time.’

The running rats were exposed to the fumes produced by the POSCO C&C non-combustible color steel. KS F 2271 requires the action stop time to be longer than 9 minutes — which means the rats must continue to move at least for 9 minutes.

The KS F 2271 assesses the toxicity of gases generated by test materials predicting the required time for evacuation. The non-combustible color steel produced by POSCO C&C satisfied the 9-minute requirement set by the KS F 2271 thereby proving its suitability in securing evacuation time by minimizing the amount of toxic gases during a fire.

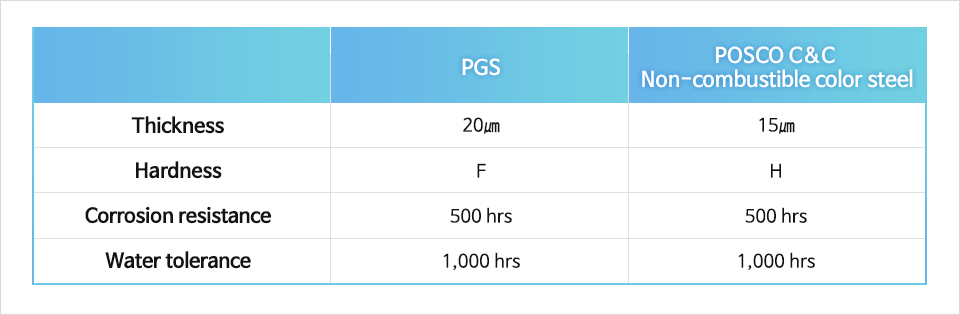

l POSCO C&C’s Non-combustible Color Steel vs Conventional Color Steel

<Non-combustible vs Conventional Color Steel>

As for the corrosion resistance and water tolerance, the POSCO C&C non-combustible color steel was on par with the Polyglycerol Sebacate (PGS), conventional building materials.

With the hardness level of H, non-combustible color steel was more solid than PGS, whose level was at H. Ultimately the result means that non-combustible color steel is more resistant to scratches.

As for the thickness level, the situation is slightly complicated. POSCO C&C representative Tae-Yol Park says, “If we solely focus on producing non-combustible steel, thin steel sheets are better. But what we’re trying to produce non-combustible color steel, without compensating the qualities the conventional color steel offered — in terms of color variations, durability, etc. in which cases it’s actually better to have thicker steel sheets.”

In this aspect, POSCO C&C was able to boost the thickness of its non-combustible color steel, while retaining the key qualities for the conventional color steel. The company’s R&D effort to boost the thickness even more is ongoing.

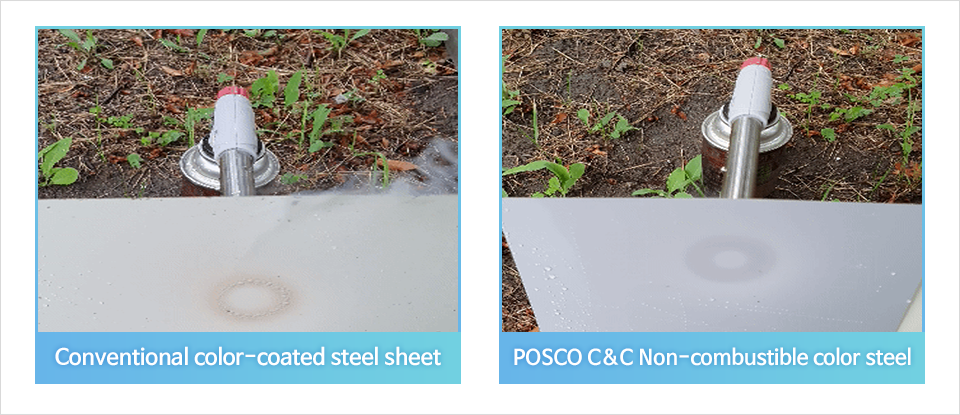

In addition to the non-combustibility test (KS F ISO) and the toxic-gas test (KS F 2271), POSCO C&C administered an internal test, a torch heating test. Both the conventional PGS and the new non-combustible color sheet were put through the testing.

When torched, PGS left a clear pattern, whereas non-combustible left relatively blurry patterns. According to Park’s explanation, clear patterns mean the material burnt more.

Park also noted that the non-combustible color steel produced far fewer fumes than the PGS. Albeit a simple comparative experiment, the low fume generation signifies that POSCO C&C’s new product is less likely to generate toxic fumes — which will help to secure more visibility and evacuation time in case of a fire emergency.

l POSCO’s Non-combustible Color Steel, What’s Next?

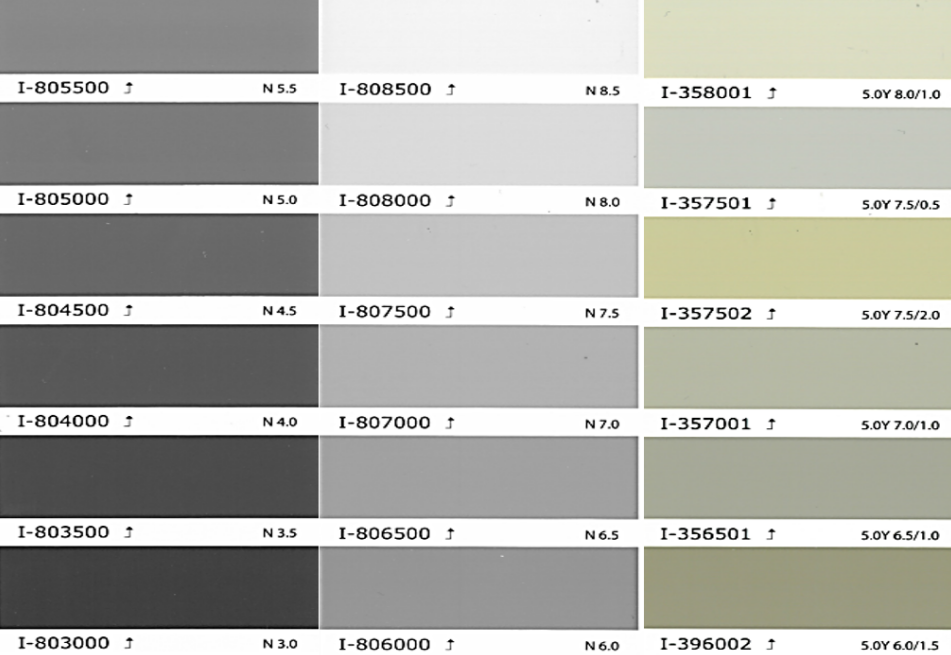

Color steel sheet is used as building exterior materials, so safety is the top priority. However, the aesthetic element is also crucial. Currently, non-combustible color steel plates are available in various tones of the following three colors: beige, grey and white.

▲ Non-flammable color steel is currently available in three colors: beige, grey, and white. The R&D endeavor continues to diversify the color tones (Image Source: POSCO C&C).

The colors are limited to the three tones because the current priority is to ensure the non-combustibility of the new product. POSCO C&C will continue the R&D endeavor to expand the color patterns into solid colors as well as metallic colors.

l POSCO C&C to Prioritize Safety and Sustainability

Non-combustible color steel has various usages. It can be used on walls, roofs, or even as solid structural material. Considering its non-flammable characteristics, however, it can best serve its intended purpose when used on the ceiling or as an interior material.

POSCO C&C’s lead researcher In-Kyu Kim addressed the challenges behind developing the non-combustible color steel sheet. Maintaining non-combustibility without compensating the qualities of the conventional color steel was the hardest, especially considering the two-month time constraint to obtain the official certification.

Despite repeated challenges and obstacles, POSCO C&C successfully developed an innovative product that will help protect buildings from fires.

Not all obstacles are gone — low-price, low-quality color steel from China makes it so easy for the industry stakeholders to opt for a quick fix over safety. The wider application of high-quality non-combustible steel can help save lives, ultimately enhancing overall safety across the country, Kim adds.

What’s next for POSCO C&C? The company will continue the endeavor to help build safer buildings. Going forward, POSCO C&C will also continue developing ground-breaking products focusing on environmental sustainability and safety.