46 years have passed since the historical moment in June 1973 when POSCO’s Pohang No. 1 blast furnace produced its first molten iron. After enduring the times of highs and lows with Korea’s key industry stakeholders, POSCO just made yet another history — the company’s cumulative crude steel production broke one-billion record.

A half-century ago, POSCO was a just new ‘kid’ in the industry but now, the company proudly ranges with the world’s top steelmakers.

One billion. The number itself is remarkable, of course, but there are countless details the number alone can’t fathom. To dig deep into what it all means, POSCO Newsroom traces the footsteps that led to the one-billion record. POSCO Newsroom reports.

l The Footsteps that Created the Legend

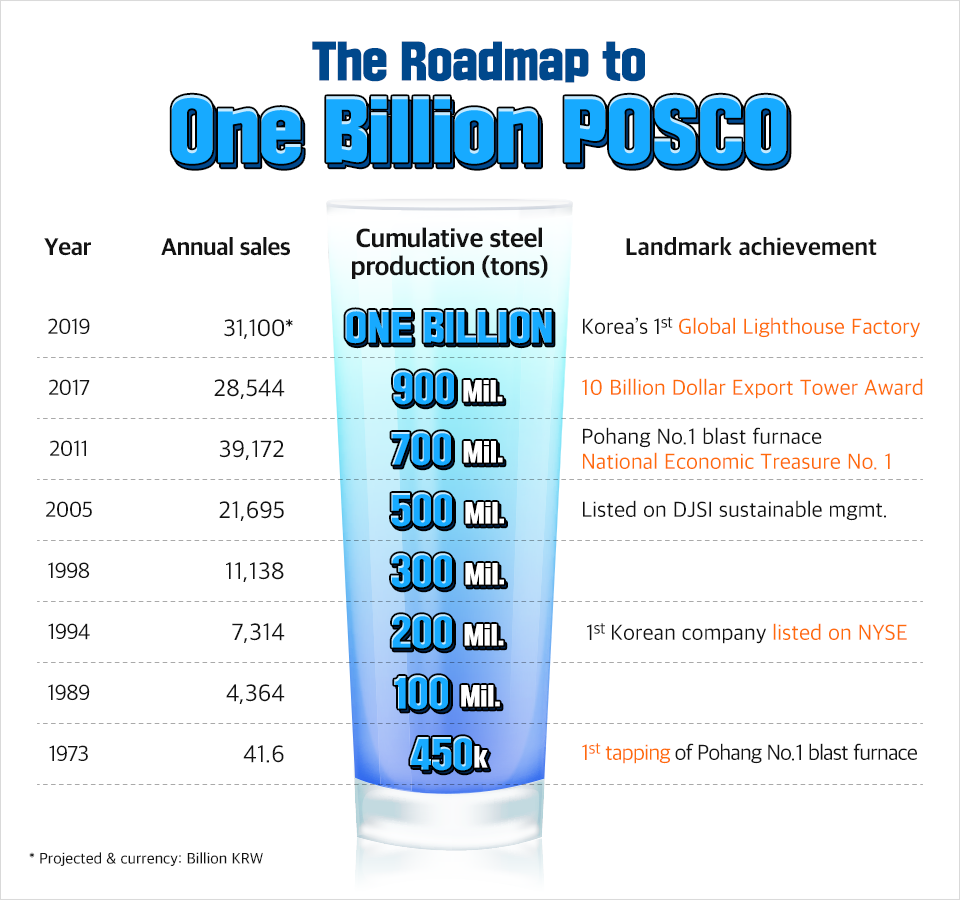

After the first drop of molten iron on June 9, 1973, POSCO shipped out its first steel products on August 1 the same year. In 1981, the company saw the completion of phase 4 Pohang Steelworks construction, followed by the opening of Gwangyang Steelworks in 1983. In 1989, POSCO achieved the cumulative crude steel production of 100 million tons. POSCO completed all construction work of then Pohang Iron and Steel Company in 1992, thereby increasing annual crude steel production capacity to 21 million tons. Since then, POSCO saw a steady increase in its production capacity, leading to the current annual production of 37 million tons of steel.

In 1994, POSCO achieved the crude steel production of 200 million tons. In the same year, the company also was listed on the New York Stock Exchange (NYSE) before any other Korean company. In 1998, POSCO’s production shot through 300 million tons, followed by 500 million tons in 2005. 2005 also marked the first year POSCO made the DJSI list for its sustainable management practice.

* DJSI Dow Jones Sustainability Index:

Launched in 1999, the DJSI evaluates a company’s sustainability performance — it’s the longest-running global sustainability benchmark worldwide and has become the key reference point in sustainability investing for investors and companies. The DJSI assesses various issues including corporate governance, climate change mitigation, and labor practices reflecting the trend to reject companies that do not operate ethically.

In 2011, the year when the cumulative crude steel production broke 700-million mark, Pohang No.1 furnace was selected as Korea’s economic National Treasure No.1 by domestic media. The company went on to received the prestigious $10 billion Export Tower award in 2017 — and finally this year, shortly after its selection of global lighthouse factory, POSCO achieved a cumulative steel production of one billion tons. The year 2019 is also the tenth year POSCO came in the top of the WSD competitiveness ranking, solidifying its stature as the No.1 steelmaker. In each year towards POSCO’s steady race to one billion, POSCO left marks of growth, both big and small.

The one-billion production was not an event created overnight. It was a long, arduous and enduring process holding the heart and souls of people in and out of POSCO communities.

l Tracing One Billion POSCO across Products

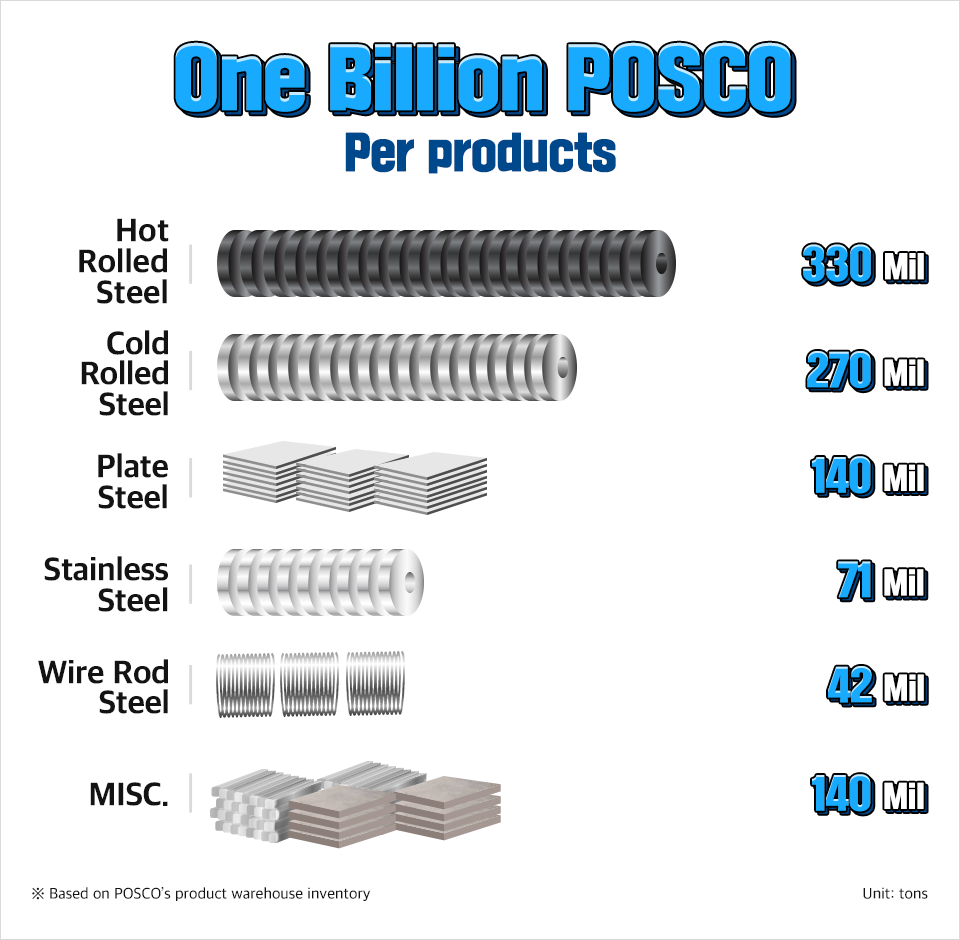

Tracing POSCO steel across different product categories —such demand industries as automobiles, construction, industrial machinery— the hot-rolled steel was the most sought-after, with 330 million tons in sales volumes.

Cold-rolled steel came in second — altogether 270 million tons were sold. This product line includes many high-end products such as GIGA STEEL and PosMAC, etc.

What about thick steel plate? As an indispensable product for Korea’s industrial development, 140 million tons of thick steel plate was produced. As for stainless steel, POSCO produced 71 million tons. In addition, POSCO produced 42 million tons of wire rod, which acts as a bridge cable, etc. POSCO also produced 140 million tons of other products which include slabs and blooms sold to other steel companies such as rolling mills.

l One Billion POSCO Went to…

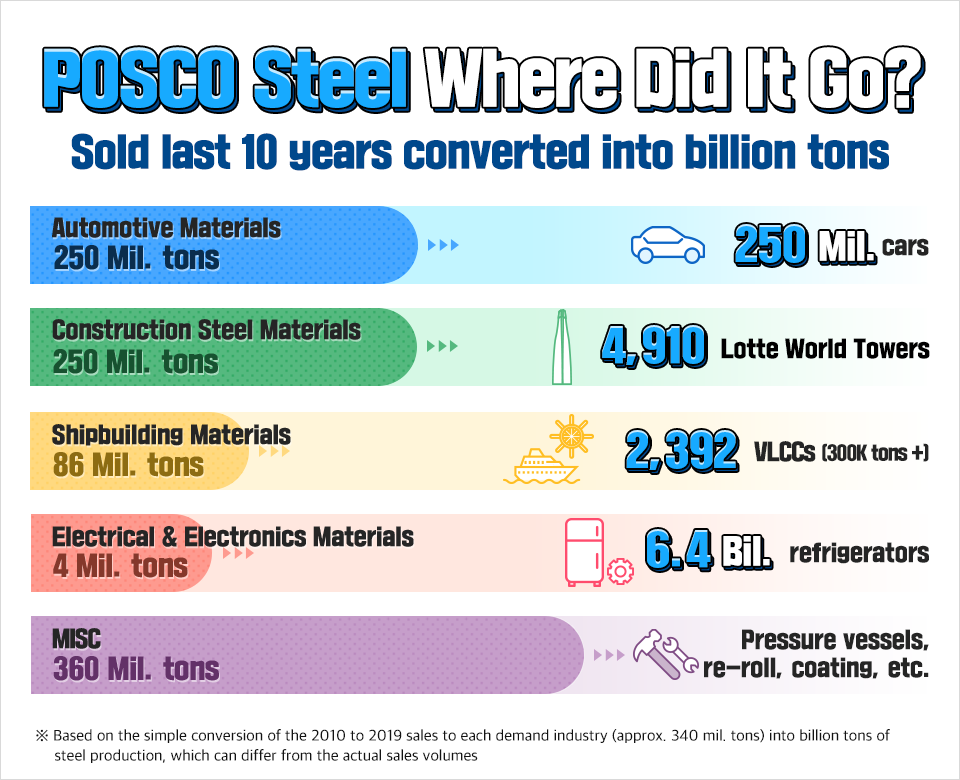

POSCO Newsroom zoomed in on the demand industries to which POSCO steel was sold for the past ten years. With 340 million tons of steel sold across industries, the auto industry and construction sector (including machinery and pipes) took 83 million tons each. The shipping industry took another 29 million tons, whereas the electrical and electronics sectors took 22 millions. 120 million tons went on to be utilized for pressure vessels, re-rolling, surface treatment, distribution, etc. To grasp what this series of numbers in millions, let’s convert these sales volumes into one billion tons of crude steel production.

50% of one billion tons were used in the automotive and construction sectors, amongst which about 250 million tons were sold to the auto industry. Presuming a midsize car weighs one ton, this means POSCO steel produced 250 million cars.

What about the construction sector? 250 million tons can raise 4,910 Lotte World Towers.

The shipbuilding industry took another 10% — 86 million tons of steel which can build 2,392 VLCCs (Very Large Crude-Oil Carriers) each weighing over 300,000 tons. The electrical and electronics sector used 64 million tons of steel which can make 6.4 billion refrigerators for household use.

The above numbers mean much more than the sheer scale of POSCO’s steel production. What they show is the fact there had been sustainable demand for steel, and that the growth of Korea’s key industries coincided with the fate of POSCO.

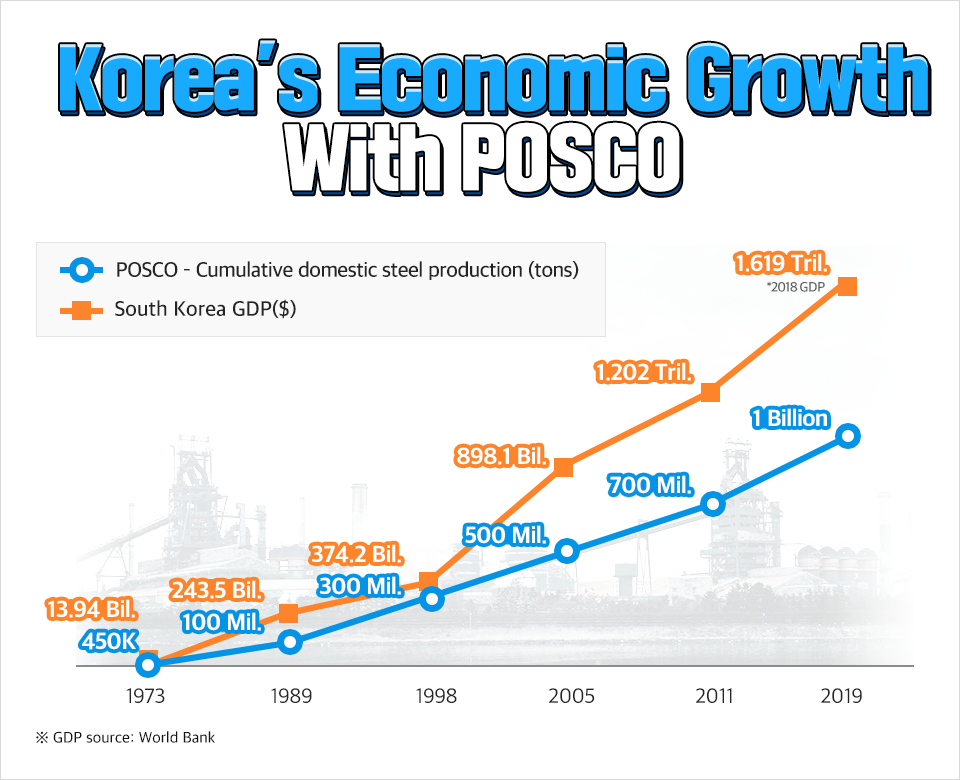

As Korea’s industries became more sophisticated and advanced, so did the country’s economic power. As the above graph demonstrates, both the historical data of Korea’s GDP and POSCO’s steel production are heading towards the same direction.

In 1973, when POSCO first produced crude steel, Korea’s GDP stood at $13.9 billion. In 2018, at the cusp of the one-billion mark, Korea’s GDP shot through the sky with 1.6 trillion, 116 times that of 1973. With the development of Korea’s downstream industries, the country’s economy advanced — so did POSCO.

As POSCO runs towards the next billion, POSCO’s unwavering support for Korea’s key industries and the global community will continue.