The recent bout of rusty tap water in the Seoul Metropolitan area brought an unexpected spotlight on one of the most popular steel products — stainless steel. Not a day goes by without us touching the material as it comes in direct contact with us — in the kitchen, at hospitals, or even at gyms when we work out. It’s everywhere.

It’s because stainless steel keeps it clean. Stainless steel keeps it safe. How? POSCO Newsroom reports.

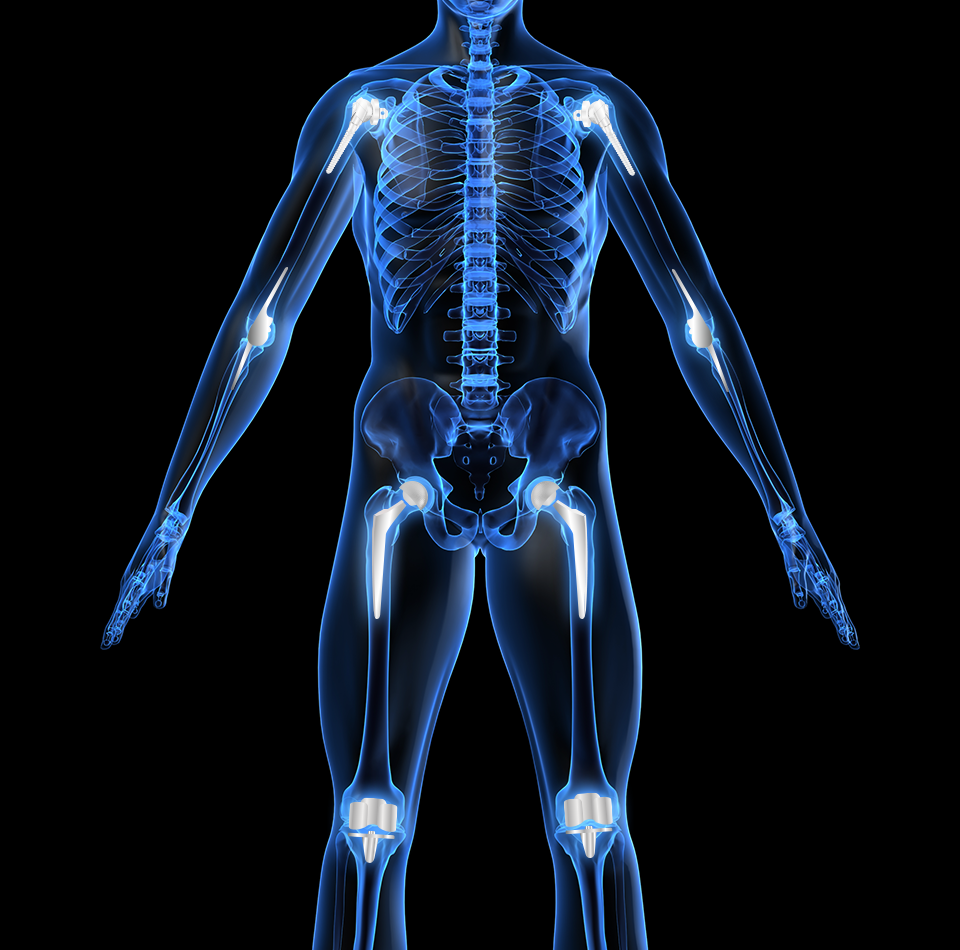

l Surgical Steel Keeps It Sterile

Surgical steel is a variety of stainless steel used in biomedical applications. It’s commonly used in scalpel, screws that stabilize broken bones, and in needles, etc. Needless to say, hygiene comes as the utmost priority. It’s highly resistant to corrosion and heat, making it suitable as biomedical material — it can also be sterilized at high temperatures.

Some commonly accepted types of surgical steel include austenitic 316 stainless steel (STS) and martensitic 440 and 420 STS. 316 STS is highly durable and corrosion-resistant alloy steel with high amounts of chromium, nickel, and molybdenum. It’s a popular material for screws and joints that hold bones together. The 420 and 440 STSs are both chromium-alloy high-carbon steel — highly durable and corrosion-resistant just like 316 STS. The 420 and 440 STSs are excellent choices for general-purpose knife steel, including surgical scalpel.

| Hygiene Starts with Squeaky Kitchenwares

The first place to spot stainless steel is perhaps the kitchen. Before STS, most kitchen utensils came in cast iron or brass. Cast irons were heavy, and brasswares were prone to rust. Aluminum took over shortly after — but aluminum was susceptible to dents.

Enter stainless steel. It practically became a go-to material for kitchenware as well as tableware, because STS is lightweight — it’s easy to wash and rust-free. STS overcame all the shortcomings of previous metal kitchenware.

Highly resistant to corrosion, and toxic-free even when boiled, stainless steel is not only cost-efficient, but it also resists the buildup of harmful bacteria — which is why STS is increasingly becoming the popular choice for the kitchen industry. From baby feeding tools, cutleries, dishwashers to water purifiers, it’s easy to spot STS in virtually all cooking materials.

In the past, stainless steel was intended mostly as internal use. However, the demand for STS as external material is increasing along with the recent hype of metallic design. STS rice cooker, for example, is made of STS inside and out. Virtually everything that comes in contact with the rice grain is STS — from the cover to inner pot. STD rice cooker not only enhances hygiene and durability, but it also creates a sense of luxury.

| Surgical Steel Accessories, Goodbye to Metallic Allergy

Extremely hygienic, stainless steel is an ideal biomedical metal as it comes in direct contact with the human body. The human body is 70% water and is rich in chloride ions, which can cause corrosion. That’s why biometals must be rust-free. Iron, gold, silver, and platinum used to be favored choices for biometals, but as of late STS is also gaining popularity.

The use of surgical steel reaches beyond the medical industry — it also makes for excellent accessories. Not only is it hygienic, but it also retains its original color even after long-term use. Compared to other metals, It is lightweight and is easy to work with. When set against gold or silver, surgical steel is more cost-efficient. It is highly corrosion-resistant, ideal for those susceptible to metallic allergies.

| Silver White Titanium, A Dream Material

Because of its eco-friendly nature, titanium is often called ‘green metal for the 21st century.’ Titanium comes in various colors and its excellent moldability is on par with that of 304 stainless steel. Not only is it corrosion-resistant, but it also requires virtually no maintenance, which makes it truly a dream material. It is 40% lighter than steel (carbon steel) but twice as strong. However, the cost of titanium is 40 to 80 times higher than carbon steel — and 10 to 20 times higher than STS.

Due to its outstanding biocompatibility, titanium is the premier biometal. Titanium creates no toxic wear or corrosion residue with minimal risks of inflammatory and toxic reactions. As for titanium implant, because of titanium’s ability to withstand the harsh bodily environment, a titanium implant is insoluble, and chemically impermeable preventing reactions between the metal and the surrounding environment even when the implant becomes loose. Titanium can also help prevent the risk of osteoporosis and bone destruction, which is why it is widely used in ergonomics and general medicine, such as artificial bones, heart valves, and implants.

| Both Steels — Still, Different All the Way

Steel products can be categorized into two main categories: carbon steel and stainless steel. Both are steel. Still, they are entirely different. By adding additional elements to Fe, the Fe becomes STS — immune to rust, i.e. stain-less, which is how it earned its nickname, ‘the flower of steel.’

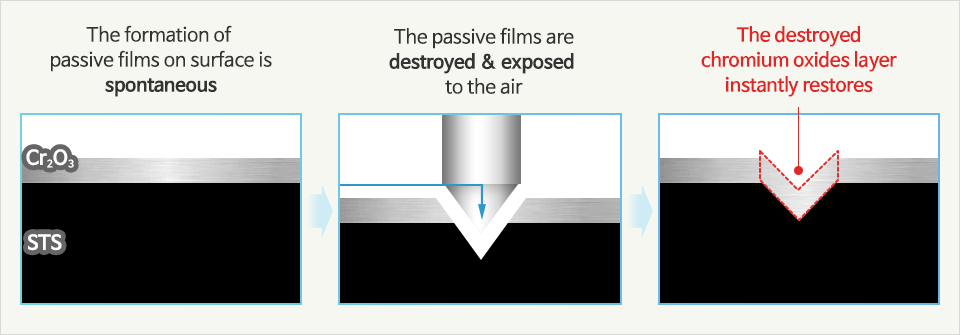

Stainless steel is an alloy steel that enhances the properties of steel by adding extra elements to iron (Fe). The core element is chromium (Cr) — and it contains carbon, nickel, manganese, molybdenum, etc. depending on its target function. The innate surface aesthetics of STS can do away with the need for additional surface treatment. STS is highly corrosion-resistant, hygienic and widely applicable. Besides, it can also mold into various shapes and can withstand high external impact.

Stainless steel can be rust-free because of the ‘passive film’ formed on the surface. This special protective film is chromium oxide (Cr2O3). TheCr2O3 is formed spontaneously through the oxidization of the chromium. Approximately 2nm in thickness, the film is so thin that it is invisible to bare eyes, but it’s extremely solid. The passive film protects the base iron from oxidization, therefore, stopping it from going rusty. Even when the film gets a scratch, it quickly regenerates as the chromium encounters oxygen again.

* 2nm is an equivalent of 2mm divided by 1 million

Due to its high resistance to fire and heat, stainless steel is being widely applied to kitchen appliances, elevators, building interior and exterior materials, as well as other electronic appliances. It’s widely utilized across major industries such as chemical and heavy industry, etc. According to the Korea Iron and Steel Association, the demand for STS stood at 1 million tons in 2018 — in Korea alone. With 27%, the auto industry had the highest demand for the material, followed by home appliances (15%), construction materials (13%) and steel pipes (11%). Annually, POSCO produces 2 million tons of STS — 60% of which the company exports.

The annual titanium production is at 2,400 tons. POSCO imports Ingot, an intermediary material from POSUK in Kazakhstan, a joint venture between POSCO and UKTMP. The company produces and sells the metallic titanium of over 99% purity by rolling it at its steelworks. POSCO’s titanium steel sheets come in various sizes: over 0.4mm in thickness, 1219mm in width. POSCO also supplies hot-rolled and cold-rolled steels, and thick plates — as coils or as sheets depending on customer specification.

As for titanium, South Korea used to be 100% reliant on imports, until POSCO launched titanium business. Thanks to POSCO’s expansion into titanium, Korea became self-sufficient when it comes to the titanium used in shipping and nuclear industries. About 90% of POSCO titanium is used in heat exchangers for power generation in shipbuilding.

| Stainless Steel: How to Keep It Longer and Cleaner

Since the invention of stainless steel, many changes have occurred in our daily lives. Hygiene, in hospitals and kitchens, has improved above all. POSCO Newsroom came up a few commonly asked questions about STS.

Q. I heard that stainless steel products should be ‘conditioned’ before first use. What does it mean, and why?

A. Manufacturing oils are applied, so the stainless steel products retain their shiny surface quality. Before using an STS product, it’s important to remove any traces of manufacturing oils.

Here is how it’s done: put a small amount of vegetable oil on a soft kitchen towel and wipe your new STS cookware. Repeat this process until all the black traces of manufacturing oils are gone. Wash it in warm, soapy water with vinegar for ten minutes. Rinse thoroughly, and it’s ready for its use.

Q. How do I remove spots on my stainless steel cookware?

A. Occasionally, white, cloudy spots can form on kitchen utensils. These spots essentially come from mineral deposits left on the surface after boiling water — they can come from both salt and/or calcium deposits.

The spot is alkaline, so it can be removed with acid. If acidic detergent isn’t available, the spots can be removed by bringing water to boil with vinegar or citric acid inside.

If the inside of a stainless steel pot ever burns, the stain can be wiped by bringing it to boil with baking soda, wiping it with a sponge afterward.

It’s always a good idea to preheat the stainless steel utensils before cooking. If you add ingredients before it is preheated, it can cause smoke and food ingredients will stick to the pan. It may take a bit of getting used to, but once you get the hang of it, you will realize the STS is one of the safest and the most hygienic cookwares.

Q. Stainless steel isn’t magnetic, but why do they sometimes stick to magnets?

A. There are indeed STS products with magnets like STS cutleries. The parts that actually stick to magnets are often ordinary steel coating, not STS.

Also, it isn’t accurate to say that stainless steels aren’t magnetic. STS is divided into austenitic, ferritic, and martensitic based on their crystal structure. Austenitic stainless steels, which are most commonly used, aren’t magnetic — but martensitic and ferritic stainless steels can be slightly magnetic, albeit weak.

Although stainless steel is spotted everywhere, until now, it wasn’t always clear why it was called ‘flower of steel.’ Stainless steel is an indispensable material when it comes to hygiene, health, and safety. POSCO will continue to research to innovate the material to make our lives even safer and cleaner.