Aluminum has long been favored as prime material for kitchen utensils due to its high thermal conductivity. However, its durability is not as excellent, so it tends to warp easily, losing its original shape. Furthermore, because of the potential risk of aluminum poisoning — its connection to a severe disorder like Alzheimer’s disease — aluminum is gradually giving its place to stainless steel.

Compared to aluminum, stainless steel is rust-free, durable and harmless to the human body, so it has been considered the best material for kitchens where hygiene is the utmost priority. However, it comes without the benefit of the aluminum’s high thermal conductivity, which puts stainless steel at a critical disadvantage. As stainless steel doesn’t spread heat as evenly as aluminum, a brilliant control in the kitchen is a tricky business with 100% stainless steel.

So what would be the answer? What is the best-suited material for kitchenware? Clad steel plate might hold the key to the solution. It’s a composite steel plate made by bonding aluminum to stainless steel. Together with a world class steel producer POSCO, KCT (Korea Clad Tech Co., Ltd) developed this innovative material, now pioneering the domestic market for clad steel. POSCO Newsroom reports.

┃Clad Steel Plate: A Modern-Day Alchemy

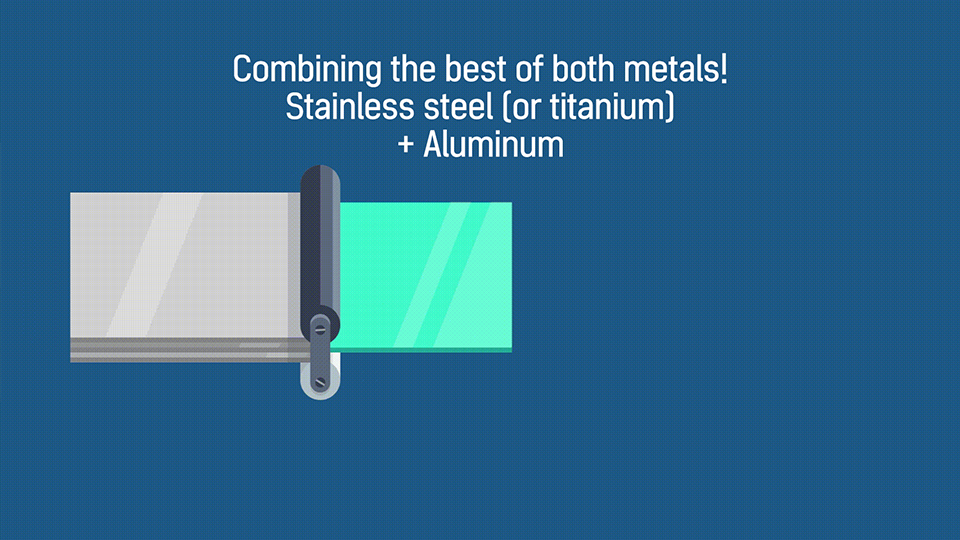

A clad steel plate is produced by combining different metals (or non-ferrous metals) using only heat and pressure. The whole process is not just about attaching different materials. It creates an entirely new product by optimizing the natural asset of each component while remedying the shortcomings of each. The clad production procedure is even comparable to Egyptian alchemy, which was all about concocting an original material through an intricate process of mingling pre-existing materials. The analogy is fair: clad production technology transforms original materials to create an entirely new element.

┃Clad Steel Plate, an Up-and-coming Star of the Kitchen

Clad steel is most welcomed in the kitchen — it’s where clad steel truly shines. Once cooking pots started using clad steel, not only did it improve food taste but it also brought convenience and hygiene up to a new level. How?

Mainly because of its high heat conductivity, most kitchenware used to be in aluminum which allowed timely cooking. On the other hand, because it is a very soft metal, it tended to warp easily — not as durable. Another to keep in mind was potential exposure to aluminum poisoning, a known cause of Alzheimer’s disease.

Of course, both stainless steel and titanium are good alternatives for aluminum as they are both rust-free, durable and harmless to the human body. Unlike aluminum, they came with no health risks and were highly hygienic. The low thermal conductivity of both materials, however, sacrificed cooking efficiency.

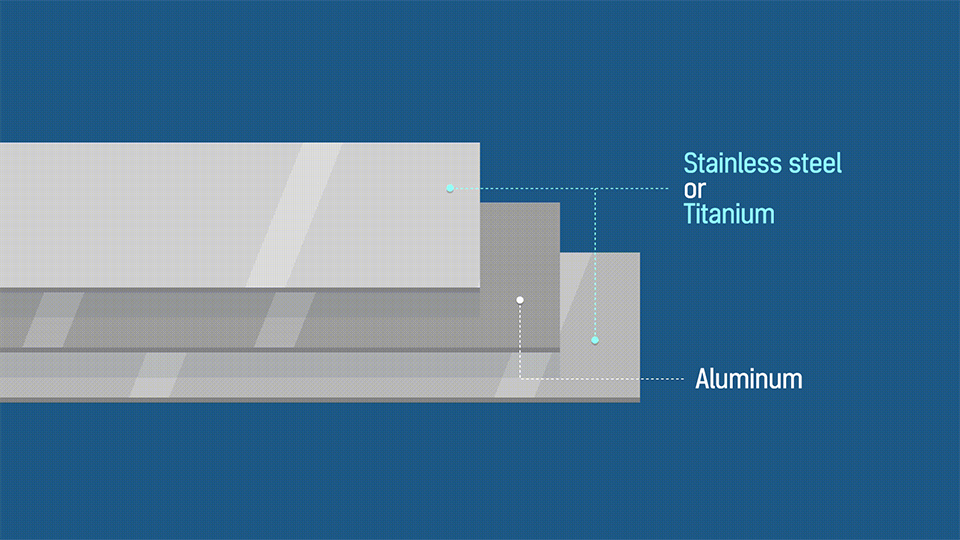

Clad steel plate comes to the rescue: it’s made by pressing stainless steel (or titanium) to the front and the rear of an aluminum plate. It’s a cutting-edge, dream union between the high thermal conductivity of aluminum and the durability of stainless steel.

“The demand for clad steel is growing. POSCO interviewed the celebrity chef Yeon-Bok Lee some time ago, who talked about how often he had to replace his cast iron wok because it just doesn’t last long. So we collaborated with KCT to custom-make a clad wok for him. He was very pleased with the product.” – Hyun-Wook Chang: POSCO Stainless Steel Marketing Dept.

┃KCT and POSCO Collaboration: Why It’s Special

On top of its pioneering role in the domestic clad steel market, KCT also invented ‘coil style rolling’ method for the first time in Korea. POSCO’s stainless steel on its part also deserves special notice. First of all, it’s exclusively developed for clad steel plate where stainless steel is the external material, which is visible. So a delicate finish is a must. POSCO meticulously adhered to all the complex polishing process required for clad steel plates, producing stainless steel with excellent moldability.

Japan used to lead clad steel industry, but KCT-POSCO partnership took Korean clad technology up a notch. Korea now produces high-quality clad steel plates whose quality surpasses that of Japanese products. Korea’s clad steel rice cooker is being exported to Japan, dominating 60% of its market for induction rice cookers.

KCT continues to spearhead the domestic clad market with its tireless dedication to new material development for various industrial components such as home appliances and automobiles, well beyond kitchen utensils. Likewise, POSCO is devoted to providing top quality steel material for clad steel plates. The POSCO-KCT joint effort that created an innovative solution out of obstacles will continue to inspire the industry as an exemplary and ideal collaboration.