Three POSCO employees keep meeting outside of work in Pyeongtaek city. The venue is an SME called HAPIS. HAPIS is one of POSCO’s client companies. Then what are POSCO employees doing here?

The POSCO Charter of Corporate Citizenship states the following: “We nurture a robust business ecosystem with business partners.” For that purpose, it continues, “We support client success by providing the finest products and services.” This is why the three POSCO employees have been getting together outside of work.

l POSCO’s Exceptional Client Support Service

HAPIS Co., Ltd. has been receiving hot-rolled steel from POSCO and producing ‘Lightweight H-shaped steel’ since 2010. ‘Lightweight H-shaped steel’ is used to reduce weights in construction, machinery, and other structures. Since it is manufactured by welding three narrow hot-rolled steel into an H-shape, welding technology is of most importance in product quality. At HAPIS, the technicians do the welding themselves, but most of the time, they utilize welding equipment called a ‘high-frequency welder’.

▲ CEO Jong-Ee Choi working with a high-frequency welder.

Despite being an SME, HAPIS was the second major manufacturer in the domestic lightweight H-shaped steel market. However, over the past decade, domestic demand has declined by more than 50%, and the struggle to compete with the market leader hasn’t been successful as well. These factors have led sales to diminish. HAPIS tried to overcome this by pioneering overseas markets in Japan, the United States, and so on but failed to meet the required product quality. HAPIS CEO Jong-Ee Choi said that it felt like he was on a dead end.

“10 years of product development is relative, but not so short. I collected all the books by my own and read and studied, but it seemed that the last puzzle was not filled. I felt like I was on a dead end.”

▲ CEO of HAPIS Co., Ltd., Jong-Ee Choi

CEO Choi spoke out his difficulties to the POSCO Marketing Office, “I want to export lightweight H-shaped steel, but the quality isn’t as good as that of competitors’. What should I do?” Suggesting a solution to this question wasn’t easy, but the following three months brought about things that made up for the last decade.

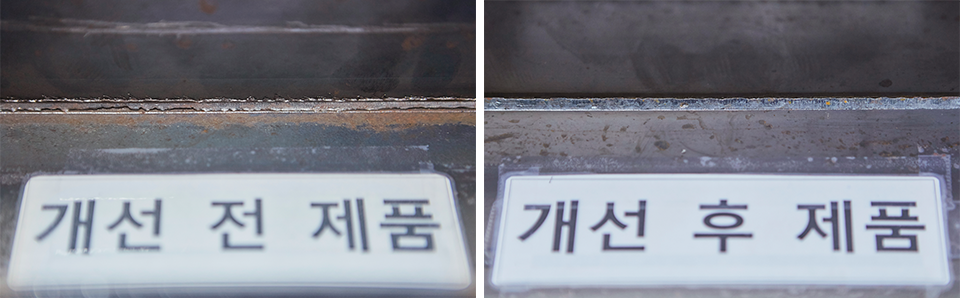

POSCO’s Joon-Ho Lee and Ho-Jin Kwon — both in charge of HAPIS at the POSCO Construction Steel Materials Marketing Office — set out for the project immediately. On comparing the competitors’ lightweight H-shaped steel products with those of HAPIS, the difference was apparent. The weld bead* of HAPIS products wasn’t as neat as the competitors’. If the bead isn’t neat, not only does it harm the appearance, but it can also cause corrosion when the product is painted or plated — thereby resulting in issues with the durability of the product. *Bead: An elongated strip of metal that is formed along the weld when welding steel

Since lightweight H-shaped steel is produced with a high-frequency welder, the importance of equipment maintenance was obvious. The Marketing Office concluded that this was the key to resolving the issue, and soon requested help from the Maintenance Technology Department of Pohang Works. That’s how a field engineer and an expert technician from Pohang came all the way to Pyeongtaek. Working on this project from September to November, their three months were quite intense.

As a result, by November, even a non-expert could identify a significant change in the quality of the lightweight H-shaped steel produced. When overseas buyers visited, they were surprised at the reformed outcome.

▲ The lightweight H-shaped steel weld bead condition of HAPIS Co., Ltd. — before the solution (left), after the solution (right).

CEO Choi said, “When you mention the service of a steel company, it’s usually about handling claims after the product is supplied. However, from my experience, POSCO’s service is different — and exceptional. A/S stands for after-sales service, but this word would be unsuitable for POSCO’s service. POSCO helps in developing the product, maintaining equipment, and it even finds customers for the products. Just like the innovation in our product quality, I could see that POSCO’s support service had also changed tremendously.”

l The Tenacity of HAPIS Sparked a Fire

This support service was special to POSCO too, since a high-frequency welder doesn’t exist in POSCO. How could POSCO utilize equipment — that they have never dealt with before — and completely transform product quality in just three months? POSCO Newsroom sat down with POSCO’s technician, engineer, and marketer at HAPIS to listen to their stories.

Q. How did the solution for HAPIS begin?

Mr. Kwon: HAPIS wanted to extend its business abroad. POSCO introduced HAPIS’ products to overseas buyers, but it didn’t work out well at the time due to quality issues. At the Marketing Office, we decided to go for another try after enhancing the quality.

Q. Why did both a technician and an engineer come together?

Mr. Cho: When the Marketing Office ask us for support, we arrange the best experts and visit the site. This time, we had to deal with unfamiliar equipment, a high-frequency welder. So we needed a technician to understand the equipment, and an engineer to theoretically verify the given solution and establish a process. That’s why technician Kim, a veteran with more than 30 years of experience in the field, and I, an engineer, have been dispatched here.

Q. Could you see any possibilities when you first came?

Mr. Kim: Actually, I was worried at first. Because there are only a few places in Korea where high-frequency welders are used. I had only seen it a few times at other client companies before, so I didn’t have much information. However, when I came here and met CEO Choi, he showed me a tremendous amount of data that he had collected while studying himself. This data was his tenacity. CEO Choi then showed me the competitor’s products. To be honest, I felt a strong urge. If someone could make it, so could we. I wanted to try it even if it didn’t seem possible.

Q. Even though you were enthusiastic, it must have been quite a challenge.

Mr. Cho: Our seniors went through a lot. They had to start everything from scratch. They found books in the library, translated them, studied them, and continued to exchange information with CEO Choi. There are some people who rely fully on POSCO and just wait for support but Mr. Choi was different. Mr. Choi continued with his research and provided the data to us. Seeing him was a huge motivation.

Mr. Kim: Many people say, ‘With 30 years of experience in POSCO, you must know everything in a glance.’ But in reality, this isn’t easy. Since the solution we provide must lead to benefits that customers can feel. Especially, in this case, we had to deal with high-frequency welders that weren’t our specialty, so I was quite worried. But I put in all my effort into this project because the Marketing Office told me that if the weld bead is revised, this client will make significant progress.

l The Real Solution Starts Now

Q. It looks like you’ve come up with a solution.

Mr. Kim: Many factors affect weld beads like the amount of electric current, the welding angle, and so on. Each factor was thoroughly diagnosed and tested. When you melt the upper and lower surface to affix it in the H-shape, a burr* is created at the melting spot. By purging** this part, we were able to tidy the bead surface. In the past, the welded steel was cooled with water-soluble coolant, but we assumed that this harms the product quality. We are currently testing this hypothesis, but we think that since the coolant is also water, its decomposition — into hydrogen (H) and oxygen (O) — interferes with weldability. Further details are the client’s core technology, so I can’t tell you more. (laughs)

*Burr: a thin, fin-shaped surplus that is formed when processing metal

**Purging: A method of blocking the inflow of oxygen using antioxidant gas to prevent oxidation of the welding spot during welding.

▲ Lightweight H-shaped steel produced by HAPIS

Q. So is the solution done?

Mr. Kwon: No. In fact, it’s just begun. The perfect solution would be the standardization of the product. We have succeeded in producing a product with the desired quality. And now we have to make sure that this continues. For example, when producing 100 products, all of them should be of this same quality. That’s standardization. If this is accomplished, the client can continue to make products with this quality without us. Our marketing must then find a market so that the products could be sold to more places.

Q. Improved product quality will lead to increased sales. Are there any other expected effects?

Mr. Cho: High-frequency welders use a lot of power, but after applying the proposed solution, we could see that the amount of electricity used was reduced. If we can weld with less electricity than before, it can reduce production costs. Currently, HAPIS pays 30 million won per month for electricity, and if the power usage is reduced by 10%, it can save the labor cost of one person per month.

l The Challenge Extended to High Strength Steel

The work on standardization is still on progress. But these pioneers don’t plan to stop here.

Q. Now that product quality has improved, what plans do you have for the next step?

Mr. Choi: In the past, I wasn’t fully sure about our products. I was aware of the weakness in our products, so I couldn’t actively venture into the export market. But now I have full confidence in our products. Some time ago, a foreign buyer visited, and he was surprised to see the improved quality of the bead. He said that if we showed this welding on high strength steel, he would like to place an order. So, with POSCO, we are looking for a solution that meets the needs of buyers from other countries.

Mr. Kwon: Each country has a different and strict welding evaluation criteria. To meet each requirement, we will supply POSCO’s finest steel materials and research welding technology that is appropriate for high strength steel. We got the quality we aimed for, so we will be supplying samples to the overseas buyers. We will join forces with other POSCO affiliates like POSCO International to help HAPIS make the deal.

Q. It must have been hard for you to go back and forth from Pohang to Pyeongtaek. How does it feel now that you’re almost done?

Mr. Kim: It’s too early to answer that question. As I told you, we still have a long way to go. (laughs) The last time we did a tensile test with CEO Choi, the results came out well, and Mr. Choi held out his hand for a handshake without a word. At that time, I realized how important this was to HAPIS. The past three months were a challenge for us too but I have to say, I could feel a sense of accomplishment too.

Mr. Cho: We’ve supported solutions to more than 30 clients this year. Some companies don’t have engineers like HAPIS, so they have no place to ask for help. Our team was organized to resolve these clients’ difficulties and share a win-win with POSCO. There are many tasks ahead, but we will do our best as HAPIS trusts us.

Mr. Kwon: POSCO’s marketing doesn’t end with selling steel. It’s also our job to support our clients who buy our steel products so that they can sell more. The clients who get our help respond by changing their steel to POSCO steel. It’s really rewarding to build trust with each other and see sales increase. As the domestic steel economy has been staggering for a long time, we will spare no efforts to support SMEs strengthen their competitiveness, and find places in overseas markets.

It is no surprise that POSCO is collaborating with various business partners — such as client companies, affiliates, and so on — to create a stable steel business ecosystem. POSCO is contributing to various aspects like product development, equipment maintenance, and market development. Since these areas are the most challenging to SMEs, and can’t be achieved in a short period of time. ‘Shared Growth’ and ‘Solution’ are some of the most used words across all POSCO departments.

POSCO hopes that HAPIS will successfully accomplish the tasks that lay ahead and succeed in the overseas market.