‘INNOVILT’ is POSCO’s premium construction material brand launched in November last year. So far, 72 products from 46 companies have been certified as INNOVILT products following three sessions of the brand committee. Client companies producing INNOVILT products become an ‘INNOVILT Alliance’ and receive full support from POSCO, including the right to use the brand name, network connections, automation data for architectural design (Building Information Modeling, BIM), and joint marketing.

For outstanding products to be widely used in the market, branding and marketing are essential. However, there is something that needs to be done first — developing the product! This is why POSCO embarks on the mission together with its client companies from the very beginning, ‘developing INNOVILT products.’

l From a Sketch on a Tissue to a New Foundation for Groundworks

On a winter day in 2017, Jong-Beom Lee, CEO of Dokun Entech, POSCO’s Jung-Hae Lee, and Dong-Wook Ahn, were talking at a coffee shop after a meeting. Dokun Entech is POSCO’s client company and specializes in substructure and ground stabilization. To create an underground space when constructing a building, it is important to dig up and make sure the ground does not collapse. The material that prevents soil on both sides of the site from collapsing is called a ‘sheathing’. The most frequently used sheathing is a small size Rolled H (RH) section steel, which looks like H-shaped steel laid sideways.

Since POSCO does not manufacture section steel, it developed Built-up H (BH) section steel made by welding steel plates instead, enabling its clients to advance into the section steel market. In the case of Dukun Entech, it was necessary to develop BH section steel optimized for groundworks. The talk at the coffee shop was also about the development of this product, and this was when a new idea struck Dong-Wook Ahn.

“It doesn’t have to be H-shaped steel, does it? Since we make products by welding, what if we add another web?

Instead of H-shaped steel, it’s going to be ㅍ-shaped steel!

It will be stronger and more efficient since it can be made lighter yet with better performance.”

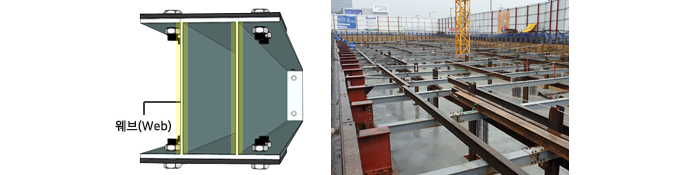

They set to work immediately, sketching the idea in detail on a tissue paper. Transforming the conventional H-shaped steel into a new ㅍ-shape seemed possible. They went straight back to their offices and labs to design this new product. High-strength steel was applied, therefore, increasing the strength of the product by more than 50 percent yet making it lighter by 20 percent. To realize it into an actual product, POSCO’s Jung-Hae Lee utilized all of his connections to find the best manufacturer. It took three months for him to find a fine manufacturer, and this was how POSCO, Dokun Entech, and Dongyang E&C came together to produce ㅍ-shaped steel. It was the first time to manufacture high-strength ㅍ-shaped steel for sheathing. The product was named Double I Beam (DIB), considering that it has two webs.

▲ A modeling image of DIB (left) and the actual product on site

Development and verification continued for about a year before the product made its debut on site. In January 2019, initial supplies were sent off to the construction site of a supermarket in Hanam, Gyeonggi Province. It was a moment when the idea sketched on a small piece of tissue became real. The response on-site was immediate. Since the product was made with high-strength steel, the amount of material required reduced significantly as well as the construction period. Workers said that their work became easier because the product was light. Since then, DIB has been applied to about ten different sites and is currently receiving proposals from various projects. Acknowledged for its marketability and innovation, the product was certified as an official INNOVILT product in the first quarter of 2020.

l Half of the INNOVILT Certified Products Are Co-developed by POSCO & Client Companies

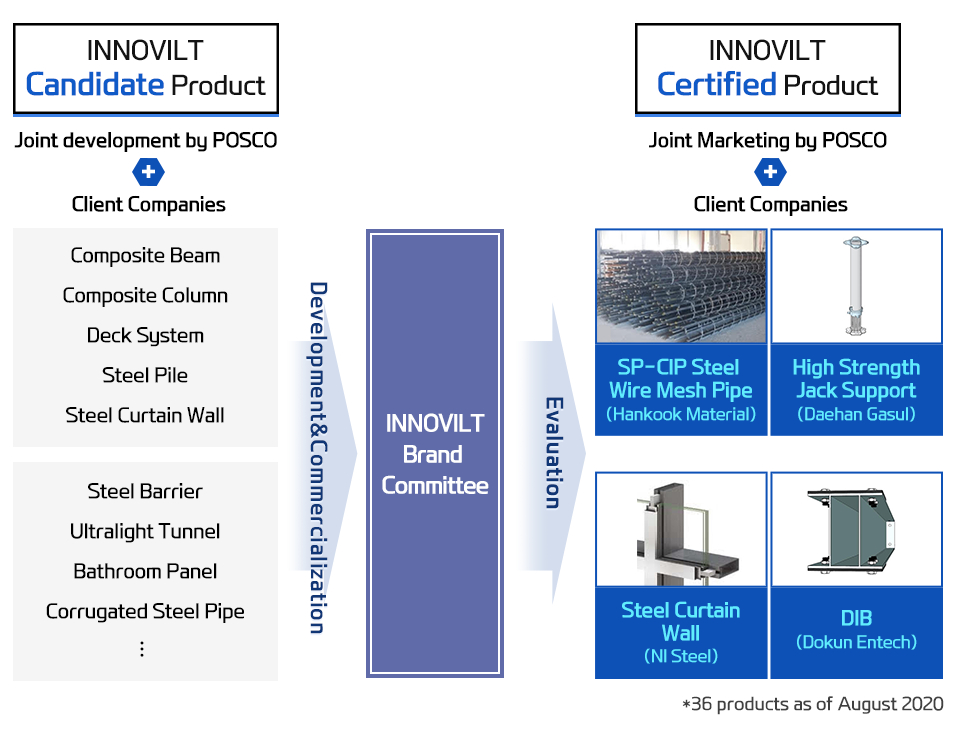

As in the case above, there are a total of 36 cases that have started with the joint development of POSCO and clients and resulted in an INNOVILT certified product. Considering that the number of INNOVILT products is 72 as of 3Q, these cases account for half of them. Some major examples of INNOVILT candidate products becoming certified products are as follows: Hankook Material’s SP-CIP Steel Wire Mesh Pipe, Daehan Gasul’s High Strength Jack Support, NI Steel’s Steel Curtain Wall, and Dokun Entech’s DIB.

▲ POSCO jointly develops next-generation INNOVILT candidate products with its client companies. Once the development and commercialization of these products are complete, products qualified as INNOVILT products are officially certified by the INNOVILT brand committee. As of the end of August 2020, 36 products were certified as INNOVILT products.

POSCO’s unique system of branding and managing client companies’ products is unprecedented — even overseas. Not only this, POSCO also works on developing products for client companies with its own resources and employees — something that is innovative in the industry. This explains why POSCO’s support for its clients is named “Full Range Solution”. With INNOVILT, a pinnacle of the value of steel, POSCO is determined to innovate construction materials in the rapidly advancing construction industry while growing together with business partners.

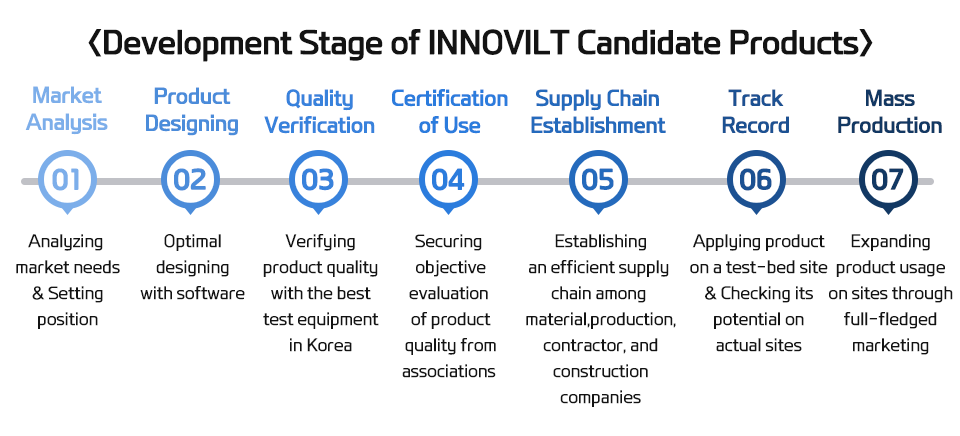

l All the Way with POSCO Experts

A considerable time of collaboration between POSCO and its client companies is required for an INNOVILT candidate product to be successfully developed and put on the market. The entire process is composed of 7 stages which are as follows: ① Market Analysis: Analyzing market needs in-depth and establishing product position, ② Product Designing: Coming up with an optimal design using various software programs, ③ Quality Verification: Verifying product quality with POSCO’s test equipment, the best of its kind in Korea, ④ Certification of Use: Securing objective evaluation of product quality from academic societies and associations, ⑤ Supply Chain Establishment: Establishing an efficient supply chain, ⑥ Track Record: Applying product in a test-site to check its practical potential, and ⑦ Mass Production: Expanding field application through full-fledged marketing.

As INNOVILT products are “premium” products that require high cost and a considerable amount of time to be developed, POSCO experts participate in the entire process. POSCO researchers are responsible for product development, from product designing, quality verification, and certification of use, to track recording. Even after the product is put into the market, POSCO analyzes its competitiveness, and if there is a need for improvement, the company conducts research task projects to supplement.

POSCO’s marketers propose developing new products to client companies by analyzing the current market. They also build supply chains to help products get to market quickly. In case an outstanding product lacks recognition in the market, the marketers propose participating in an exhibition or work to strengthen joint promotion. Simply put, POSCO works together with its client companies from the beginning of product development to the end process, marketing.

POSCO holds a brand committee every quarter to select INNOVILT products and to provide active support making sure that these INNOVILT products are utilized in the market as premium construction materials. In addition, POSCO plans to reach out to clients and conduct R&D so that innovative products can be developed continuously. POSCO will continue taking these unprecedented steps in hopes that they would help business partners and strengthen the overall demand industry.