The trends in POSCO Group’s flagship business area are explained by experts in an easy-to-understand manner. In this third installment, we discuss the latest 3R trend in the steel industry to realize a circular economy with insights from Jong-min Lee, a senior researcher at POSCO Research Institute. We explore various topics, including the influential 3R trend in the global steel industry and POSCO’s energy-saving initiatives.

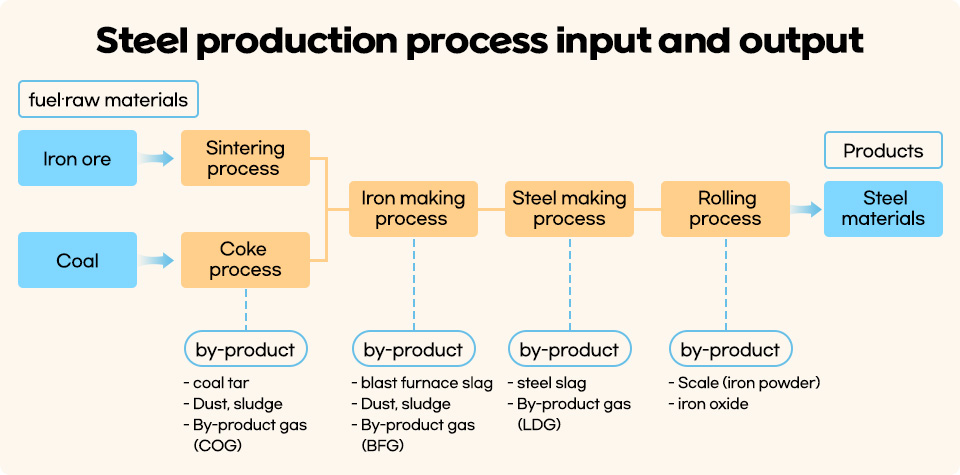

In recent times, there has been a growing social and economic push towards eco-friendly industries that conserve natural resources and minimize environmental impact. Consequently, the steel industry is striving to develop innovative and sustainable solutions to enhance by-product recovery rates and improve quality during steel production.

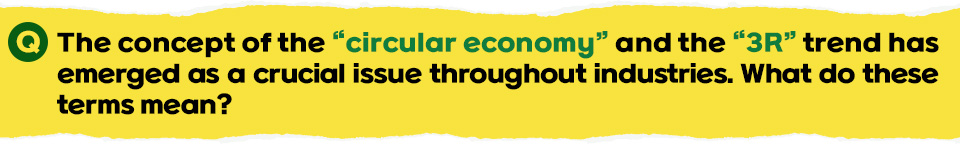

The 3R campaign is an environmental movement that first emerged in Wales, UK, in 2008. It started with the concept of Reduce, Reuse, and Recycle, aimed at reducing waste, reusing items, and actively using recycled products. As this concept entered industries, 3R technology in the industrial sector sometimes expanded to include new ideas such as Recover, Replace, and Rot, forming what some call the 4R framework.

For example, the chemical industry applies the concept of “Rot” to develop technologies that make plastic products more biodegradable to minimize environmental damage. The concept of “Replace” involves developing technologies to substitute hazardous or harmful substances with safer alternatives. However, it can be challenging to distinguish these new concepts from the traditional 3R, and their applicability may vary depending on the industry.

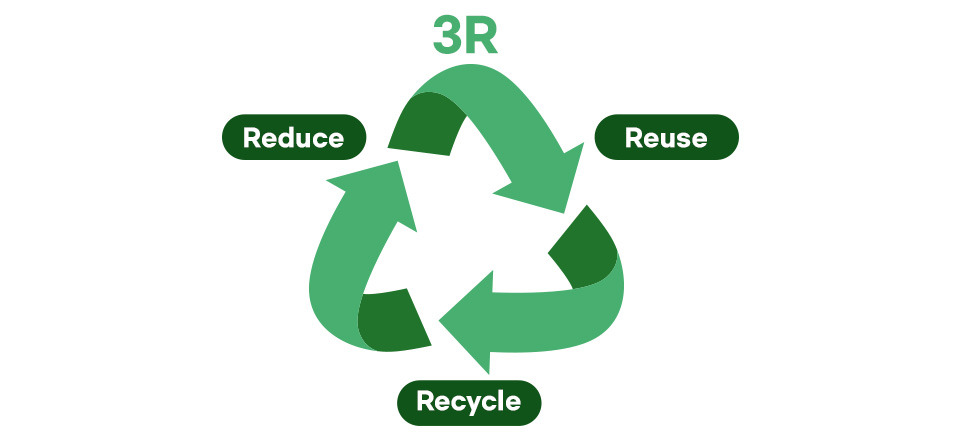

As the emphasis on the circular economy grows in the steel industry, the 3R trend is becoming increasingly prominent. In the steel industry, 3R technologies can be categorized into Reduce, Recover, and Recycle. Reduce technology focuses on reducing the amount of energy and raw materials used during steel production. This includes efficient product design, optimization of production processes, and enhancing energy efficiency. Recover technology involves reclaiming by-products or waste generated during production for reuse or other purposes. Recycle technology pertains to breaking down used products or raw materials for reuse or repurposing them for other applications.

The steel industry, being energy-intensive, focuses on developing technologies that reduce energy consumption. Specifically, various technologies are being developed around the blast furnace process, which has the highest energy consumption in steel manufacturing. A notable technology is hot oxygen injection technology, spearheaded by the U.S. Department of Energy (DOE), which is currently in the pilot stage. This technology injects hot oxygen into the blast furnace, increasing productivity by 15% compared to traditional blast furnaces and maximizing steel production per unit of energy. Blast furnace heat recuperation technology, which reduces fuel costs by using exhaust gases from the blast furnace to preheat combustion gases, and plasma blast furnace technology, which uses the plasma extensively used in the chemical and metallurgical industries to minimize metal loss, are other well-known energy-saving technologies.

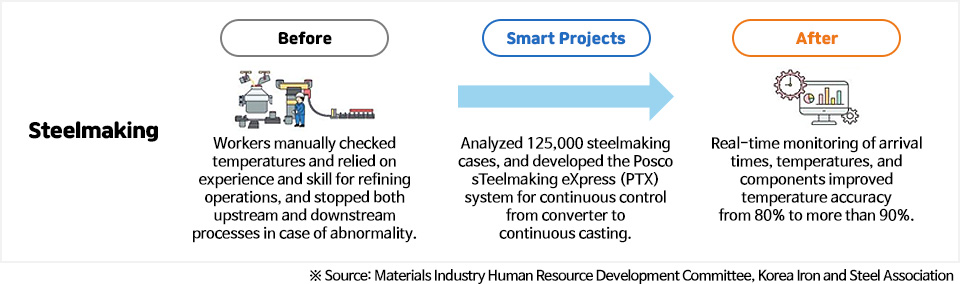

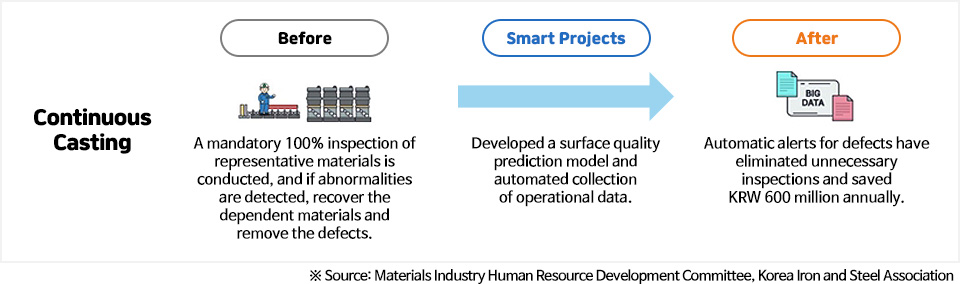

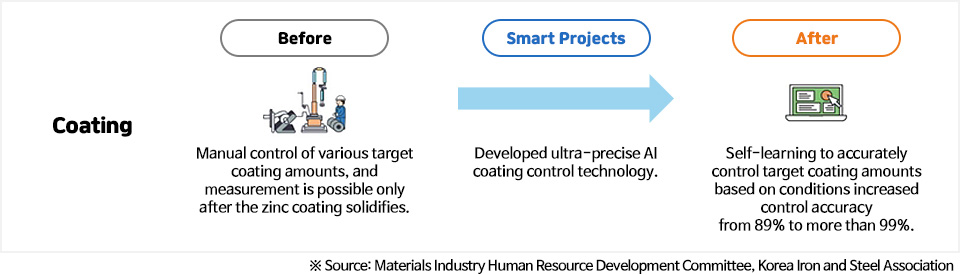

Smart factory technology improves yield during steel product manufacturing, resulting in raw material and energy savings. The implementation of smart factories can lead to reduced defect rates, shorter decision-making times, reduced unnecessary inventory or equipment failures, fewer accidents, and faster abnormality response times.

POSCO’s steelmaking process uses AI to learn and adjust temperatures, components, and raw materials, raising temperature accuracy from 80% to more than 90% and reducing raw material use by around 60%.

POSCO’s continuous casting process previously required 100% surface inspection of representative materials and expanded to all materials upon defect detection to remove imperfections. After implementing smart factory technologies, KRW 600 million was saved annually by applying a surface quality prediction model that inputs quality criteria into AI to analyze and select defective materials.

In POSCO’s coating process, deep learning is used to autonomously learn and precisely control the steel grade, thickness, width, operational conditions, and target coating amount, thereby increasing coating control accuracy from 89% to more than 99%.

While new processes are being developed to achieve carbon neutrality, it will take considerable time to commercialize hydrogen reduction technology. Considering sunk costs, existing blast furnace facilities must continue to be used. Therefore, energy-saving technology development for currently used blast furnaces is expected to be active. With the advancement of AI technology, smart factory technology will be competitively adopted by steel companies and become the hottest area for technological competition.

In the steel industry, Recover technologies focus on reclaiming by-products or waste generated during production for reuse or other applications. This practice has led to a remarkable global efficiency rate of 97.3%.

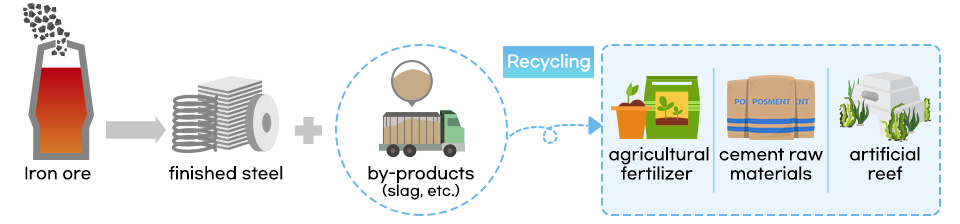

Globally, the proportions of steel products, by-products, and waste generated during steel production are approximately 64.4%, 32.9%, and 2.7%, respectively. Among these, slag, a representative by-product, is used as a raw material in the cement and fertilizer industries or for road construction and asphalt. Dust contains valuable elements such as zinc and iron, which are recovered and reused.

Slag

Slag is the most significant by-product in steel production, with more than 400 million tons produced annually. Blast furnace slag, in particular, is used as a raw material for cement or fertilizers. Slag, a by-product from iron ore separation, is classified into blast furnace slag and steel slag based on its origin. Blast furnace slag is a hot molten slag generated during the production of molten iron. Rapidly cooling this slag with high-pressure water in a closed system produces granulated slag, while slow cooling in a yard forms air-cooled slag.

Granulated blast furnace slag is used as an eco-friendly alternative to limestone in cement production. Increasing the ratio of slag used in place of limestone can reduce limestone usage by approximately 45%, and the lower heat of hydration when cement reacts with water can reduce concrete cracking and enhance durability and strength. Air-cooled slag and steel slag are used as aggregates in civil engineering to curb excessive quarry development and save energy in aggregate extraction and processing.

By-product gas

By-product gases from coke ovens (COG), blast furnaces (BFG), and converters (LDG) contain methane (CH4) and carbon monoxide (CO). These gases have sufficient energy to be reused as fuel. Power plants compress by-product gases with gas compressors to produce primary power in gas turbines and secondary power in steam turbines by recovering hot exhaust gas. By-product gases are 99% recovered and reused or used for power generation.

The development of by-product recovery technologies in the steel industry has achieved notable success over the decades. By using by-products as raw materials in industries such as cement and fertilizers, the industry has established exemplary supply chains. Using air-cooled and steel slag as civil engineering aggregates has minimized environmental damage by reducing excessive quarrying. Recover technologies maximize the eco-friendliness of the steel industry and require continuous technological advancement and development.

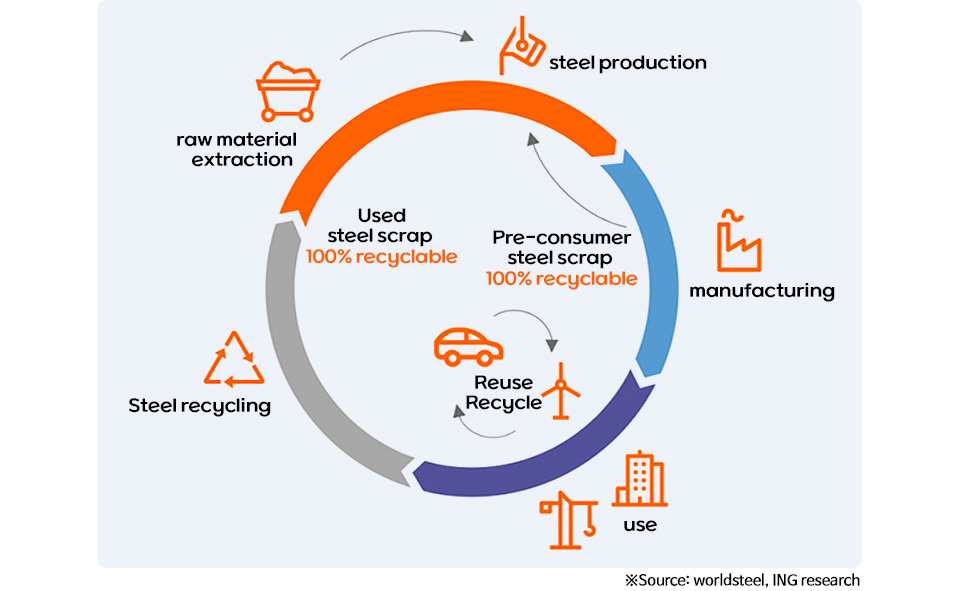

Recycle technologies involve breaking down used products or raw materials for reuse or repurposing them for other applications. Currently, various recycling technologies related to steel scrap are being developed in the steel industry. Steel scrap is a major raw material in electric arc furnace (EAF) steelmaking, and recycling technologies are being developed to reduce CO2 emissions in blast furnace processes through low hot metal ratio (HMR) operations.

Tramp Element Removal Technologies

A notable Recycle technology in the steel industry is the removal of tramp elements from steel scrap. Elements such as copper (Cu) and tin (Sn) in steel scrap are challenging to remove or separate, making it difficult to produce high-purity steel products. Research focuses on effectively removing these elements in the EAF process. For copper, methods such as low-temperature shredding, aluminum solution immersion, and wet processes involving ammonia solutions containing amine ions are being developed. Various physical and chemical methods are also being explored for tin removal.

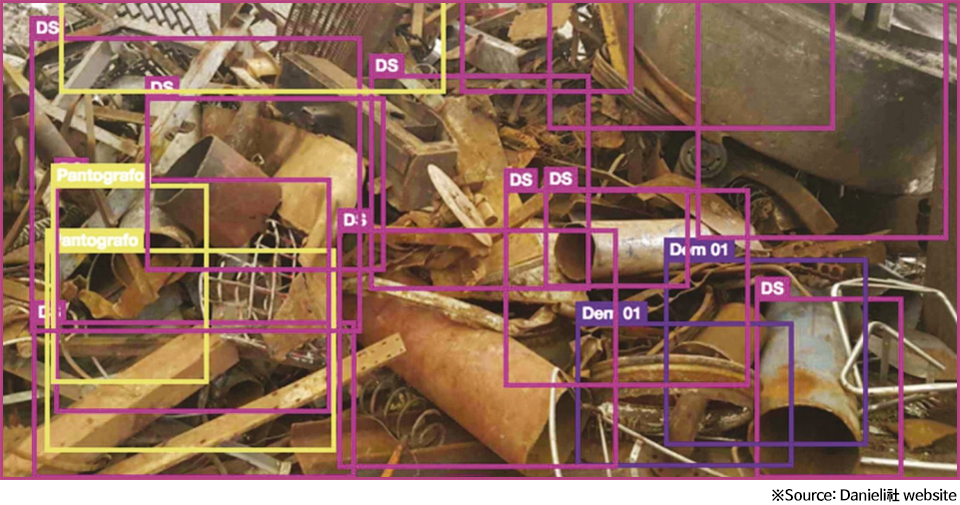

AI-based Scrap Inspection Systems

AI-powered scrap inspection systems are also being developed. Recently, automated visual inspection using AI has been actively pursued to increase steel scrap recycling efficiency. Before recycling, steel scrap is classified into various grades, such as light, heavy, and pig iron, and undergoes impurity content analysis. Previously, manual visual inspections by workers led to frequent errors and safety issues. By introducing AI-based visual inspection automation, it is possible to accurately classify and inspect scrap grades and quality based on data, thereby improving accuracy and reducing costs. Japan and China have been competitively developing this technology for the past 2-3 years. Although Korea has yet to widely implement steel scrap sorting systems in the industry, it has entered the development and validation phase.

Blockchain Technology

While not yet widespread, blockchain technology is gaining attention as a solution for traceability, transparency, and certification issues in the steel scrap industry. Blockchain can record and document transactions and transport conditions, providing reliable records at each stage from collection to processing.

Drone Utilization Technology

The use of drones to observe sites in real time from the air can preemptively address safety issues in steel scrap yards and minimize accident risks. Drones equipped with cameras and sensors also enable innovative inventory management.

The most actively developed areas in recent years are smart factory technologies and steel scrap-related fields. From the perspective of Reduce, smart factory technologies increase yield and reduce energy consumption, and their application scope is expanding with technological advancements. The steel scrap industry, particularly highlighted in the low-carbon era, sees active investments and efforts to increase recycling rates using AI and drone technologies for collection and sorting.

POSCO is also envisioning a bright future in the rapidly evolving steel industry through the lens of the 3R concept in the circular economy trend.