Take a look at the crème de la crème of the Steel Wire’s stories in 2017 – it’s not difficult to see why they topped the list.

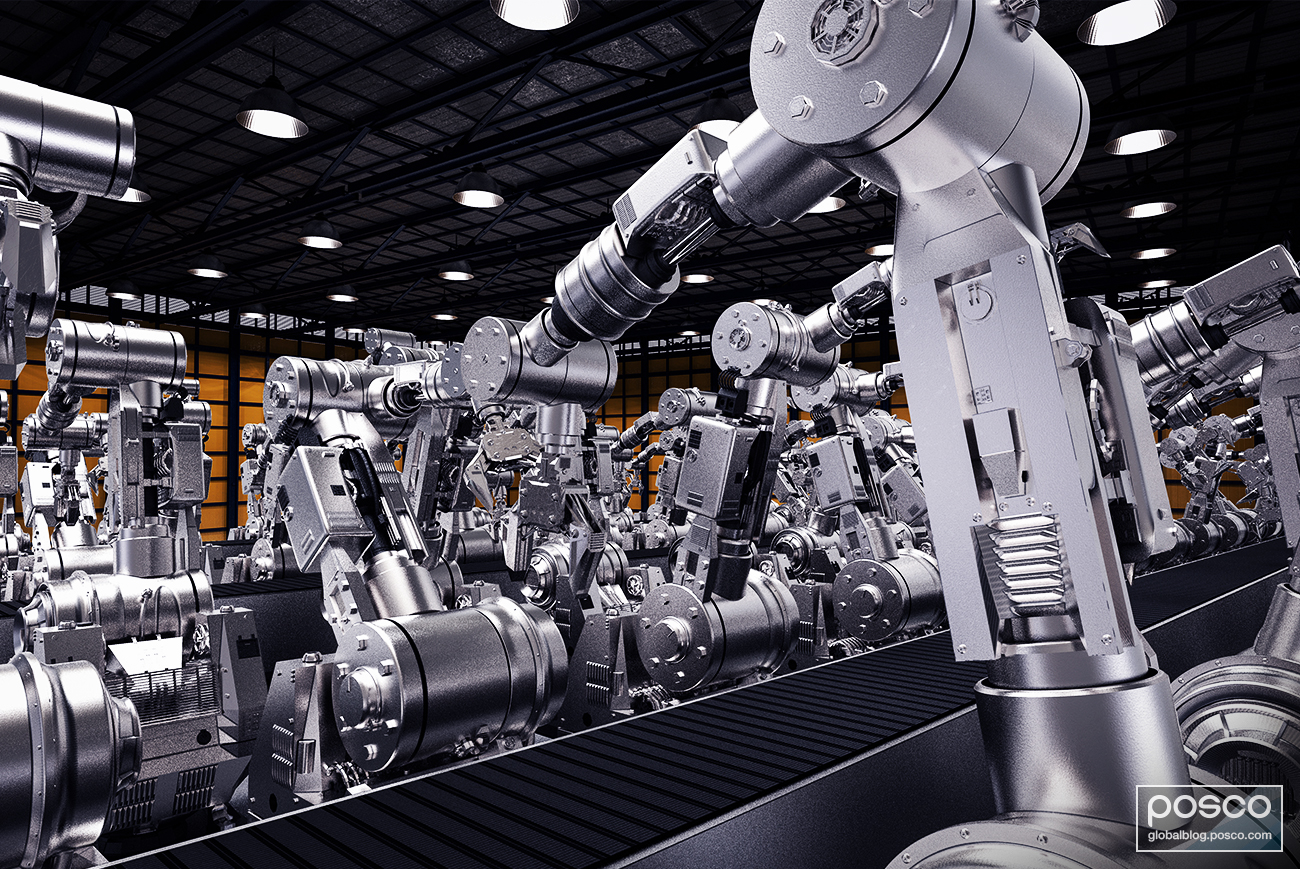

#1 How Smart Factories are Changing the Manufacturing Industry

The Fourth Industrial Revolution is bringing AI, IoT and other automated technologies into people’s lives and changing the way they live and interact with one another. It is also bringing about change in the manufacturing industry as more companies embrace smart factories to further enhance efficiency, performance and safety. Take a deeper look at how smart factories are reinventing the manufacturing industry.

SEE ALSO: How Factories Produce Steel- the Smart Way

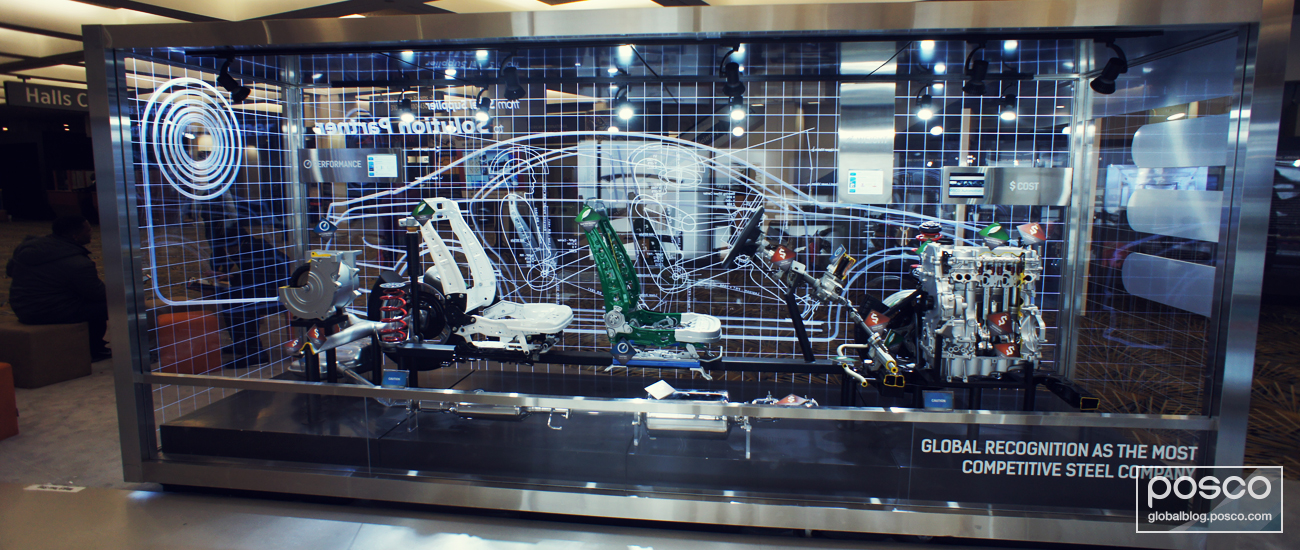

#2 POSCO GIGA STEEL Increases Strength, Improves Safety in Autos

This year, POSCO GIGA STEEL set a new, industry standard for strength and formability for auto steel. The advanced high-strength steel (AHSS) is an automaker’s dream come true as it falls into the strongest category of steel commercially available today. Plus, its lightweight property makes it the perfect solution for manufacturers trying to design safe, high-performing and sustainable vehicles.

SEE ALSO: Ask an Expert: Has Steel Achieved Its Peak in Lightweighting?

Lithium-ion batteries are found in some of the most popular devices available today. (Source: BGR)

#3 POSCO’s Innovation Shapes the Ever-Growing Lithium Market

POSCO is the world’s 5th largest steel producer, but it’s got more up its sleeves than just steel. This year, POSCO developed game-changing technology that extracts lithium from water in just 8 hours to one month. Traditionally the task takes anywhere from 12 to 18 months. To add, the new technology can achieve a purity rate of 99.9 percent and increases the lithium recovery rate to over 80 percent.

Lithium is a central component in rechargeable batteries for electronics such as smartphones, laptops and most importantly, electric vehicles (EVs). Heading into 2018, POSCO is well-positioned to be an industry leader in a rapidly-growing market for EV batteries.

SEE ALSO: The Fuel of Tomorrow: Mining Lithium for Tomorrow’s Cars

#4 POSCO Gets “Smart” with Pohang Blast Furnace No.3

In June, one of POSCO’s oldest and the world’s 5th largest blast furnace got a makeover with some added AI. After undergoing 102 days of repairs, Pohang Blast Furnace No.3 came back much bigger with an expanded furnace volume of 5600㎥, compared to its original volume of 3795㎥ from its beginnings in 1978. Plus, Pohang Blast Furnace No.3 now has smart sensors to monitor operations and detect malfunctions or accidents before they happen.

SEE ALSO: How to Make Steel with an Old(ie but Goodie) Blast Furnace

Ajay Telrandhe in Quality Assurance and Manish Kochar & Chetan Waghchoure in Sales talk to the Steel Wire.

#5 Ask an Expert: POSCO Leads India’s Growing Automotive Steel Market

POSCO Maharashtra is POSCO’s leading subsidiary. Three of their employees gave the Steel Wire an insider’s look into the company’s success, despite a challenging market environment and government restrictions. The team in India implemented positive changes in the company’s steel quality, production processes and customer service to become a leading solution-provider for their automotive partners.

SEE ALSO: Revving Up for Growth: India’s Automotive Market is In Full Gear

EVs, autonomous vehicles and shared mobility will drastically change the auto industry. (Source: Electrek)

#6 Ask an Expert: Electric Vehicles and the Future of the Automotive Market

Stephen Zoepf, executive director at the Center for Automotive Research at Stanford University, was the first speaker at POSCO’s 2017 Global EV Materials Forum. Zoepf shared his vision of what the future automotive market will look like and its implications for car manufacturers, suppliers and drivers. According to research, 60 percent of the cars in the U.S. will be running on electric batteries by 2030, and those cars will mostly be part of a shared mobility service. Traditional ways of car production, distribution and consumption will undergo massive change and companies will have to find ways to stay competitive in the new market dynamics.

SEE ALSO: The Forgotten Fleet: Looking Back on Early Electric Vehicles for a Better Future

#7 Ask an Expert: Fashion Forward with Steel

Fashion designer Naim Josefi opened new possibilities for steel application with his 2017 F/W GANGS collection which included dresses made of elaborate steel sequins and laser-printed jeans. He is also known for his 3D-printed high heels that provide the perfect fit. The artist has a passion for fusing technology into his work and finding more sustainable ways to create beautiful clothes and says he will continue to use steel as a high-tech, fashion material.

Heading into a new year in 2018, the Steel Wire promises to be the best source of steel industry news and continue to provide exclusive, insightful and interesting stories.

- 2017

- 2017 global ev materials forum

- advanced high strength steel

- AHSS

- AI

- auto

- automotive

- automotive market

- automotive steel

- best stories

- blog

- blog stories

- building

- cars

- communication

- construction

- culture

- customer service

- design

- development

- Electric Vehicles

- energy

- environment

- equipment

- EV

- evs

- future

- global

- GM POSCO

- growth

- high-tech

- history

- how to

- India

- industry

- international

- iron

- Korea

- lithium

- lithium ion

- lithium-ion battery

- manufacturing

- manufacturing industry

- marketing

- material

- metal

- most popular

- most-read

- Naim Josefi

- plant

- pohang blast furnace no.3

- POSCO

- POSCO GIGA STEEL

- POSCO Maharashtra

- production

- research

- safety

- sales

- smart

- smart factories

- Smart Factory

- solution

- stainless steel

- steel

- Steel dresses

- steel industry

- steel mill

- steel production

- steel products

- steel wire

- steelmaker

- steelmaking

- structure

- sustainability

- sustainable

- tech

- technology

- The steel wire

- top news

- top stories