On June 4, Korea Iron & Steel Association (KOSA) hosted the 20th Steel Day and SteelKorea 2019 at POSCO Center in Seoul to celebrate the 20th National Steel Day. About 400 industry stakeholders attended the event.

In an effort to pave a path to sustainable industry future, SteelKorea 2019 dedicated a session to the industry’s up-and-coming concept, Life Cycle Assessment (LCA). Toshio Isohara, an LCA specialist from the Japan Iron and Steel Federation (JISF), presented his research on the topic. What insights does his work provide for POSCO who has been making a sizable investment towards clean steel initiative since its establishment? POSCO’s Newsroom reports.

l Throughout Life Cycle, Steel Is Environmentally Friendly

How sustainable is steel? Demonstrating the sustainability of steel in comparison to other materials involves applying the LCA approach.

LCA refers to Life Cycle Assessment, which is a technique to evaluate environmental impacts associated with all the stages of a product’s life from raw material extraction, through manufacture, to disposal and recycling.

When applying the LCA approach, the environmental impact of steel becomes much less compared to other materials. In other words, steel is more sustainable.

Just how sustainable is steel, really?

(1) Steel equals high carbon emission? Per-kilo emission is low!

Steel is often blamed for high carbon emission, but that can be attributed to the high volume of steel production, not steel itself. When it comes to per-kilogram CO2 emission, the CO2 output is significantly less than other materials.

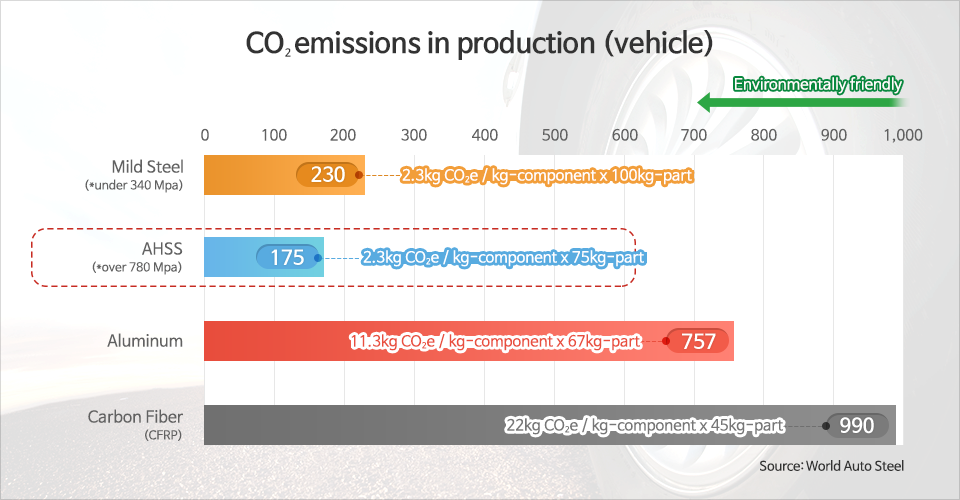

The CO2 emission from the steel manufacturing process is less than other major lightweight materials. However, since steel production is overwhelmingly massive compared to other materials, the total amount becomes much higher. The chart below demonstrates when producing automotive parts of the identical function, the amount of CO2 emission of steel is much less.

▲ Presented by Toshio Isohara at SteelKorea 2019

Let’s compare aluminum with advanced high-strength steel (AHSS). Assuming the production of same auto parts with identical function, 75 kg of AHSS will be required – for aluminum, only 67 kg will be needed. In this scenario alone, aluminum is the clear winner. However, the CO2 emission of AHSS at the production stage is 2.3 kg per kilogram – however, aluminum emits 11.3 kg of CO2 per kilogram. The CO2 generated by AHSS is about 20% of CO2 emission by aluminum.

(2) High-strength steel – sustainable and lightweight

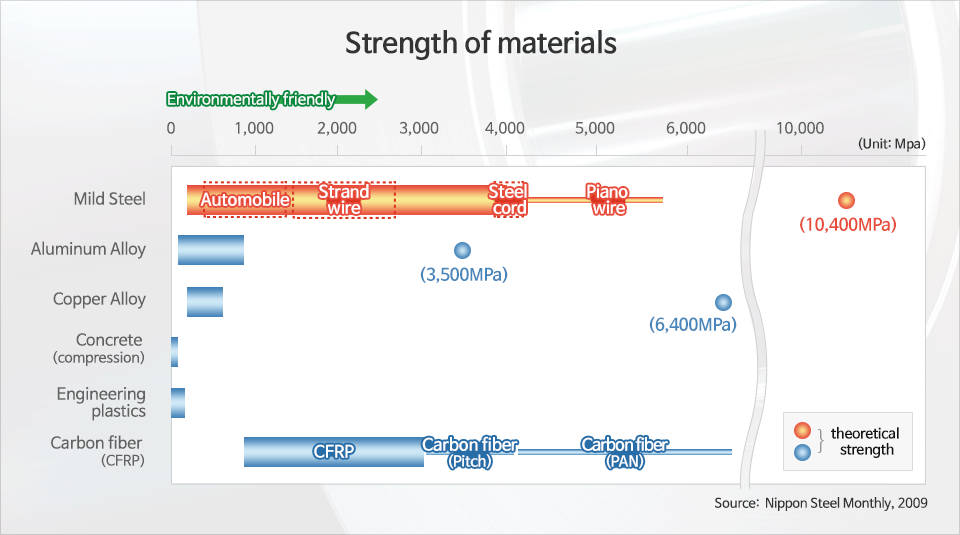

Per same strength, the weight of steel is getting even lighter than aluminum. Applying lightweight steel to vehicles improves fuel efficiency while contributing to reducing greenhouse gas (GHG) emission.

▲ Presented by Toshio Isohara at SteelKorea 2019

The strength of steel exceeds almost every material presented above save for the carbon fiber. The range of strength is also widespread, so it can be applied to automobiles, strand wires, tire cords, etc. Furthermore, with the theoretical strength at 10,400MPa, steel exceeds that of aluminum (3,500MPa) or concrete (6,400MPa), which means steel has even more potential for lightweighting. As technology advances, when building vehicles of identical strength, the required thickness for steel gets lower and lower, bringing down the overall car weights – all in all reducing total environmental impacts.

(3) The more, the better: multiple recyclability of steel

The magnetic nature of steel makes it easy to separate from other materials boosting its recyclability. Once scrap steel is separated, it doesn’t get used straight away but any residue of chemical impurities must be separated so only pure steel can be extracted and recycled. Any impurities in steel scrap can be easily removed through oxidation process through which whole new steel is born.

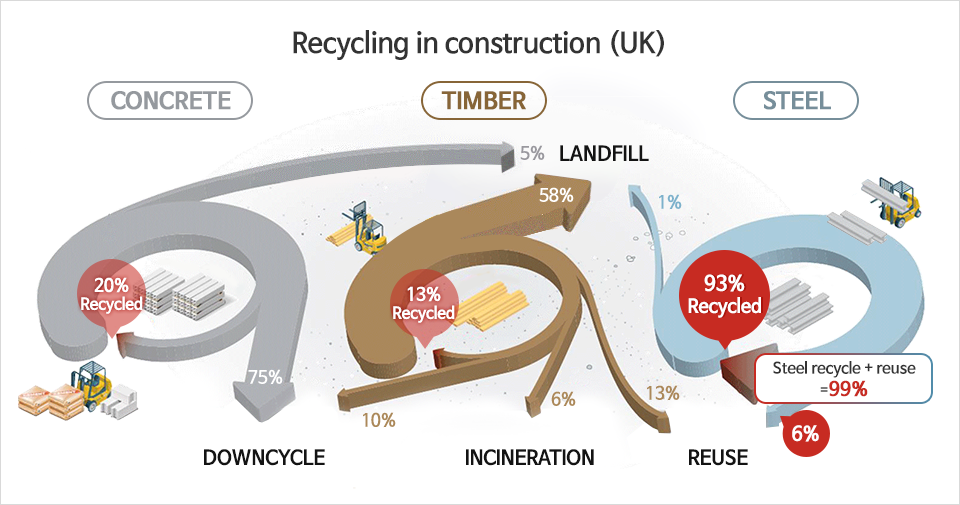

How do we quantify and calculate the recycling effect of steel? The premise behind such calculation is that steel follows ‘closed-loop’ system and can be recycled infinitely. Most materials are ‘open-loop’ in which case downcycling occurs. Downcycling deteriorates the value of original material whereas steel retains its original value even when recycled. The following graph describes the steel recycling rate in construction, which is much higher than concrete or wood.

▲ Presented by Toshio Isohara at SteelKorea 2019

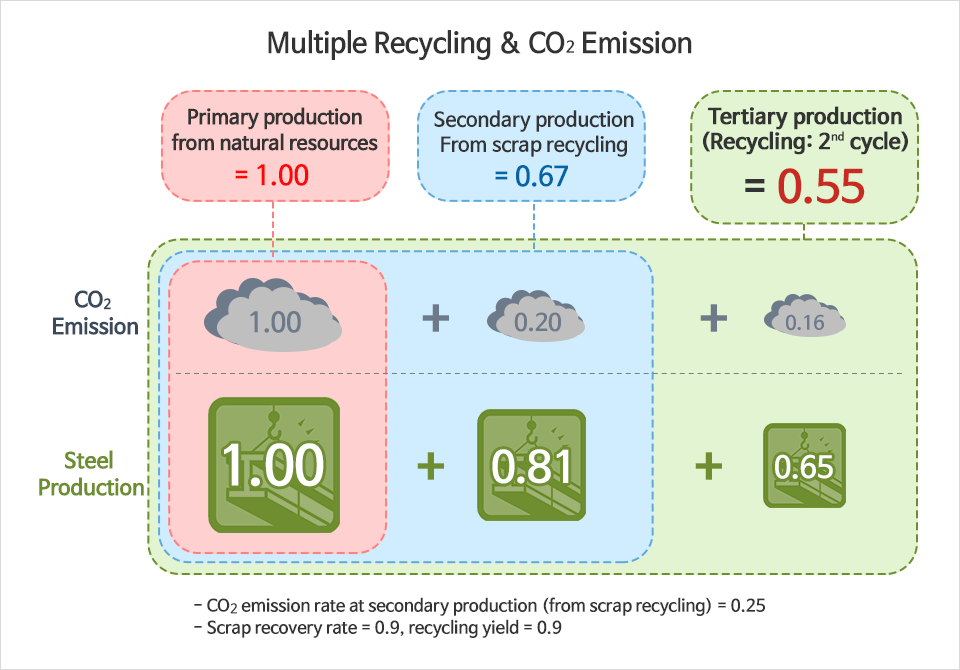

Now, let’s calculate the recycling effects of steel. In the past, the calculation only considered the first cycle of recycling. However, when taking steel’s multi-recyclability into consideration, the amount of CO2 generated in the entire process should be divided by the total amount of steel production.

Source: JSIF – Presented by Toshio Isohara at SteelKorea 2019

The above calculation takes a product’s whole life cycle into consideration. A is the amount of steel production, and B is the amount of CO2 in the same stage. Both A and B in the primary production stage are set at 1.00. At the second production stage, using steel scrap – the total amount of steel becomes 1.81 (1.00+0.81), and the total CO2 at the same stage becomes 1.20 (1.00 + 0.20).

The amount of CO2 generated per steel production (B divided by A) reduces to 0.67 at the second stage (1st stage 1.00). Using the same calculation, the amount of CO2 per steel production at the third stage becomes 0.55 – almost halved when compared to the first stage of 1.00. From such LCA perspective, it can be surmised that the rate of CO2 emission gradually reduces because of the infinite recyclability of steel in a closed-loop system.

l l Promoting steel sustainability

Steel sustainability is of little use if it doesn’t become common knowledge. That’s why JISF is taking meticulous steps to promote the eco-friendliness of steel by recycling water and steel byproducts like slags while striving to improve energy efficiency.

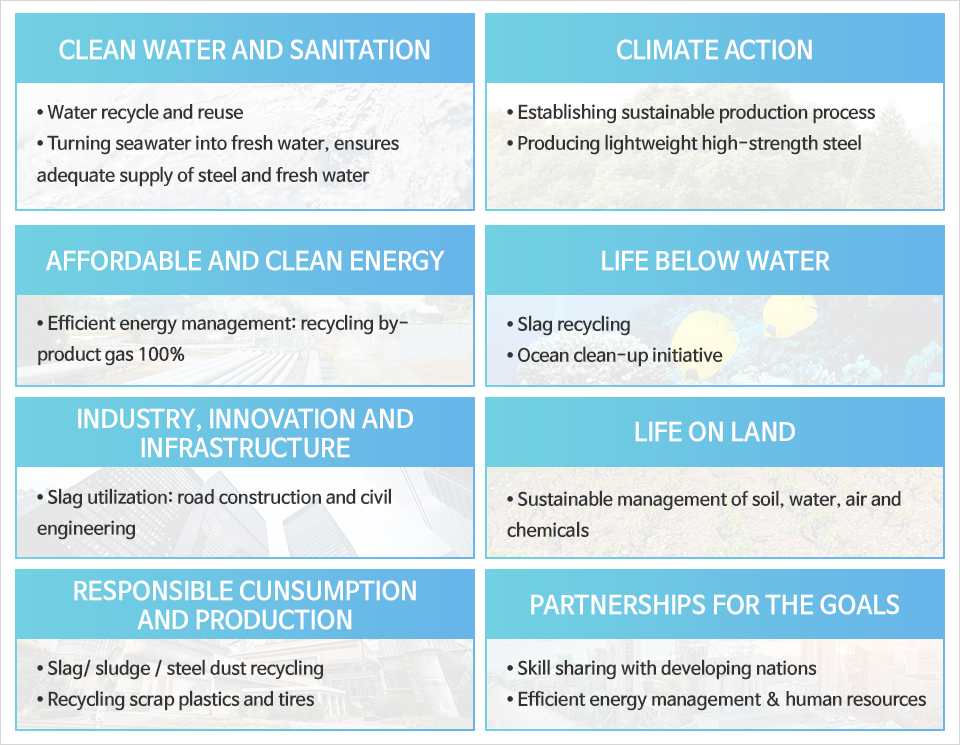

▲ Environment-related activities of the Japan Steel Federation reported to the UN SDGs (Sustainable Development Goals)

More specifically, under the three pillars of Eco Process, Eco Product, and Eco Solution, JISF strives to reduce environmental impacts in the entire life cycle of steel. Japan’s spirit of Monozukuri plays a particularly important role here.

* Monozukuri refers to the spirit of Japan’s manufacturing practices. It includes a sincere attitude towards production with pride, skill, dedication and the pursuit of innovation and perfection.

▲ Source: JISF – Presented by Toshio Isohara at SteelKorea 2019

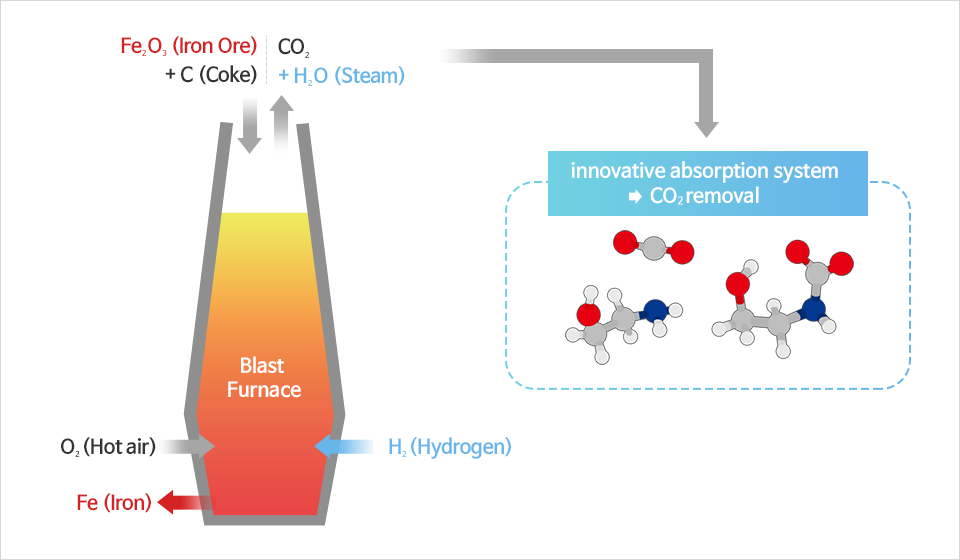

Currently, JISF is developing COURSE50, a blast furnace technology utilizing hydrogen. What lies at the heart of this technology is the reduction of CO2 by transforming iron ore into hydrogen, which can reduce CO2 emissions by approximately 30%. Research and development are underway to commercialize it by 2050.

There is also an effort to develop Japanese industry standard (JIS Q 20915) in parallel with the international standard, ISO 20915. This standard requires recycling effects to be included in the calculation of LCI. The early draft version of the JIS Q 20915 has been adopted last March, and the full transfer just completed on June 20.

**LCI refers to Life Cycle Inventory. LCI involves the compilation and quantification of inputs and outputs for a product throughout its life cycle. Inventory flows include inputs of water, energy, and raw materials, and releases to air, land, and water.

In addition, JISF’s LCA-focused exhibition, Eco Pro, was favorably received both by visitors and the industry in the eco-friendly product exhibition held in Tokyo in 2017 and 2018 – visitors had the opportunities to appreciate the value of steel from an LCA perspective.

▲ LCA promotion clip from NSC: Nippon Steel Corporation: Click to watch

JISF’s endeavor to promote steel sustainability from LCA perspective bore fruit in the form of Grand Prize at the Japan LCA Forum Awards, sponsored by the Japan LCA Association. JISF also produced promotional video clips on steel recyclability. It can be streamed online but will also be promoted on public transportation like trains, in the hope to raise public and industry awareness on the sustainability of steel.

l Persistence is the key for disseminating LCA perspective

In the world we live in, where environment issue is a matter of global concern, steel is undeniably a competitive material. From the LCA perspective, JISF will seek constant communication with our consumers as well as with end users in order to publicize the sustainability of steel. Along with industry stakeholders, we will do our part, and more, to help improve the global environment by advancing steel sustainability and developing quality products.

※ This article is based on Mr. Toshio Isohara’s presentation at SteelKorea 2019 and the article published in ‘Japan Steel Daily Report Vol.20’ in December 2017.

· Nippon Steel Corporation

· LCA Working Group Leader, Japan Iron and Steel Federation (JISF)

· worldsteel LCA Expert Group