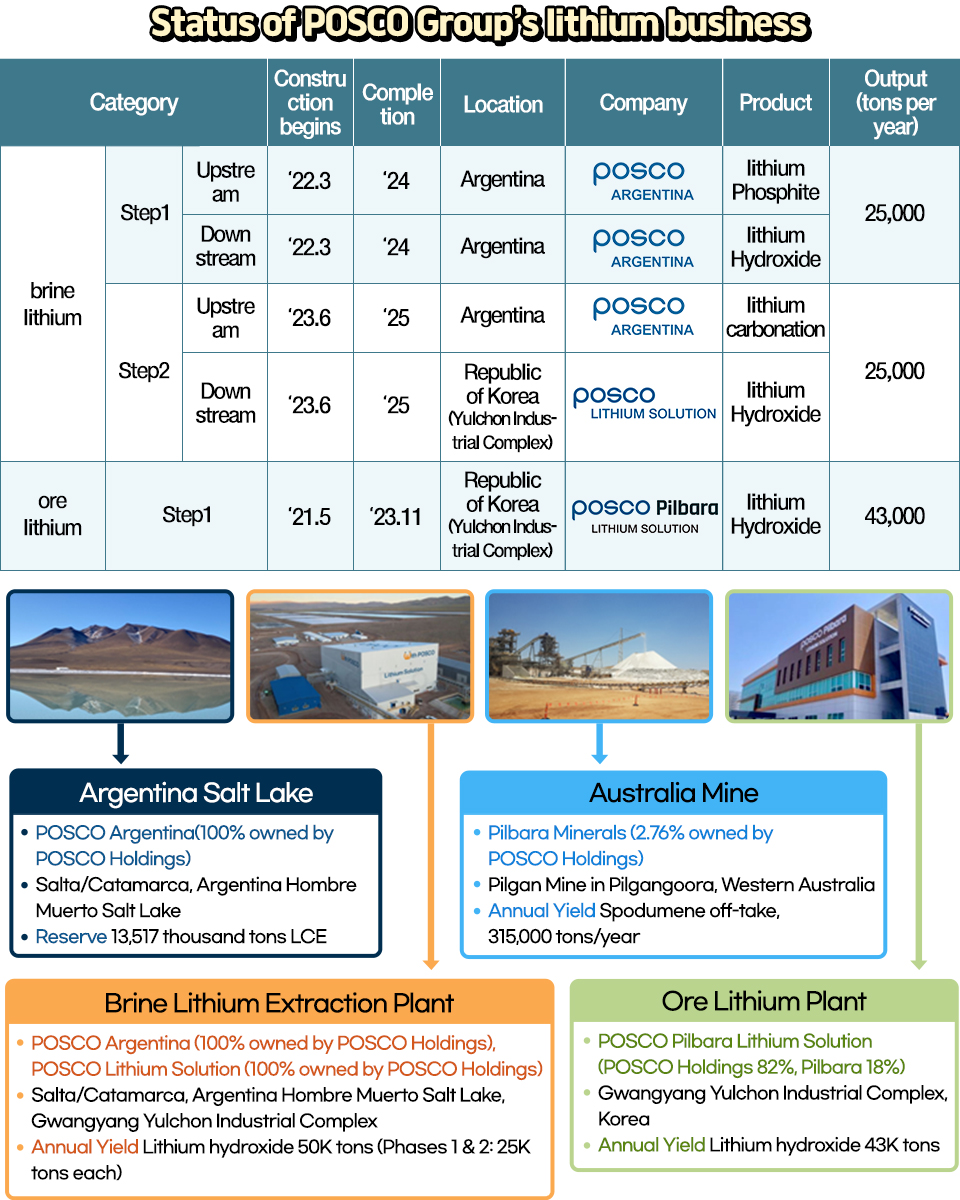

Since its transition to a holding company structure in March 2022, POSCO Group has aimed to achieve balanced growth and maximize corporate value by focusing on seven core businesses, including △steel, △rechargeable battery materials, △lithium-nickel, △hydrogen, △energy, △construction-infrastructure, and △agri-bio. With the completion of the POSCO Pilbara Lithium Solution plant in November 2023, POSCO Group reached a milestone in building a full value chain in the rechargeable battery materials business from key raw materials to advanced materials production.

Completion of a Supply Chain for the Rechargeable Battery Material Industry Within 3 Years… Accelerating Investment with a Focus on High-Yield Raw Materials

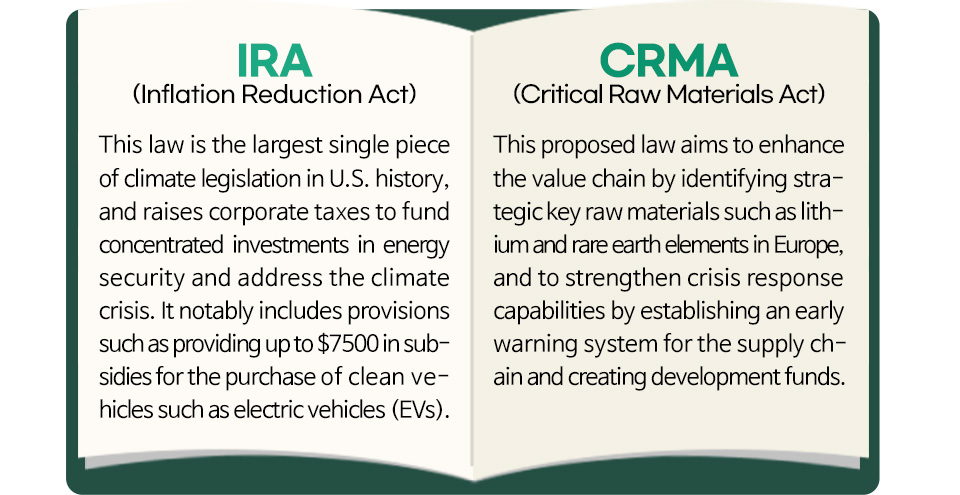

Recently, the United States and the European Union have announced sector-specific regulatory policies, including the Inflation Reduction Act (IRA) and the Critical Raw Materials Act (CRMA), with the objective of developing a domestically centered network for the rechargeable battery industry. POSCO Holdings is directing its focus on securing key raw materials, such as lithium, to establish a resilient supply chain and build the capacity to adapt flexibly to market dynamics.

In particular, POSCO Holdings predicts that the value-added aspects of raw materials in the supply chain will continue to rise as the rechargeable battery materials market expands. It considers the next three years to be a crucial time to strengthen the supply chain in the rechargeable battery materials industry, and is accelerating investment focusing on materials that generate high returns.

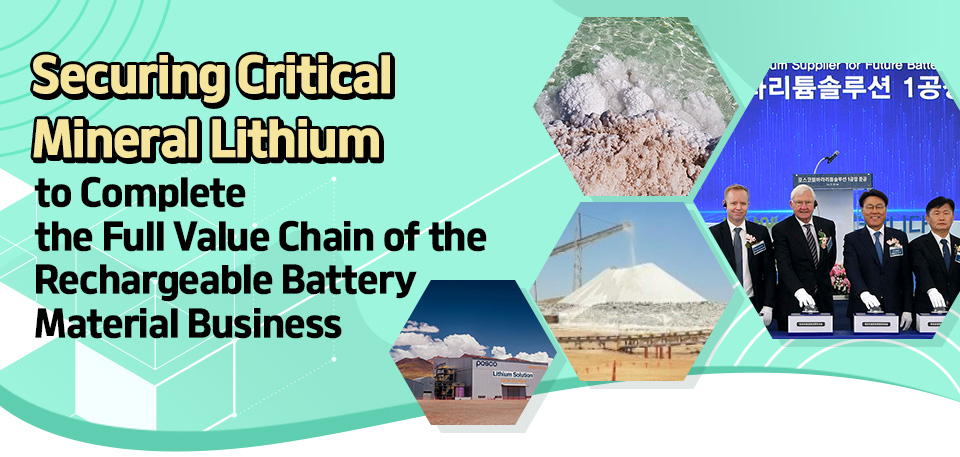

▲Lithium processing site mined from an Australian mine acquired by POSCO Holdings (left) and Hombre Muerto Salt Lake in Argentina.

In 2018, POSCO Holdings strategically acquired stakes in a lithium ore mine in Pilbara, Australia, and exclusive lithium brine rights in Argentina to secure multiple stable sources of lithium raw materials.

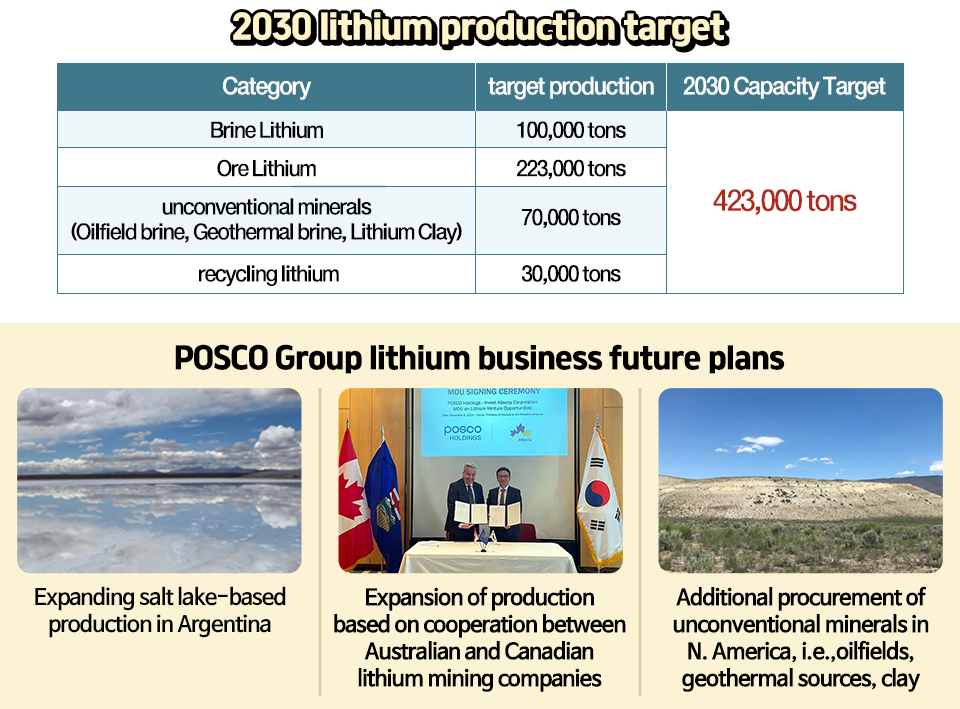

Since then, POSCO Holdings successfully entered the market using resources from the Australian mine and Argentine brine. The company is now expanding its business by using unconventional lithium resources. Its goal is to secure a lithium production capacity of 423,000 tons by 2030 and become one of the top three global lithium companies.

[Ore Lithium] Successful Localization of Lithium Hydroxide Production with the Completion of Lithium Ore Production Facilities

Lithium ore production began on November 29 last year with the opening of the POSCO-Pilbara Lithium Solution Hydroxide Plant, which has an annual capacity of 21,500 tons.

▲POSCO Group completed the construction of the POSCO Pilbara Lithium Solution lithium hydroxide plant at Yulchon Industrial Complex in Jeollanam-do on November 29 last year. From the left, POSCO Future M President Kim Jun-hyung, POSCO Holdings Future Technology Research Institute Director Kim Ji-yong, Pilbara Minerals CEO Dale Henderson, Pilbara Minerals Chairman of the Board of Directors Anthony Kiernan, Chairman Choi Jeong-woo, National Assembly member Seo Dong-yong, Lee Seung-ryeol, Director of the Industrial Policy Office of the Ministry of Trade, Industry and Energy, and Park Chang-hwan, Deputy Governor of Jeollanam-do for Political Affairs.

This is the first commercial production of high-purity lithium hydroxide for electric vehicle batteries directly from lithium ore raw materials in Korea, and POSCO plans to increase the production capacity to 43,000 tons by 2024.

▲Overview of POSCO Pilbara Lithium Solution.

In addition, POSCO plans to not only expand its ongoing collaboration with Pilbara Minerals in Australia in the second phase, but also expand partnerships with promising lithium mines in Canada. The goal is to increase production of lithium hydroxide from lithium ore to 220,000 tons by 2030.

In particular, the entire process of producing lithium hydroxide at the POSCO Pilbara Lithium Solution plant, from sourcing raw materials (in Australia) to processing them (in South Korea), takes place in countries covered by the U.S. FTA. Therefore, benefits under the Inflation Reduction Act (IRA) are expected. Currently, only Korea and Australia have a trade agreement to produce lithium hydroxide from ore, with three plants, including the POSCO Pilbara Lithium Solution plant (excluding the U.S.).

[Brine Lithium] Establishing an annual production system of 100,000 tons by 2028…

Enhancing Lithium Self-Sufficiency

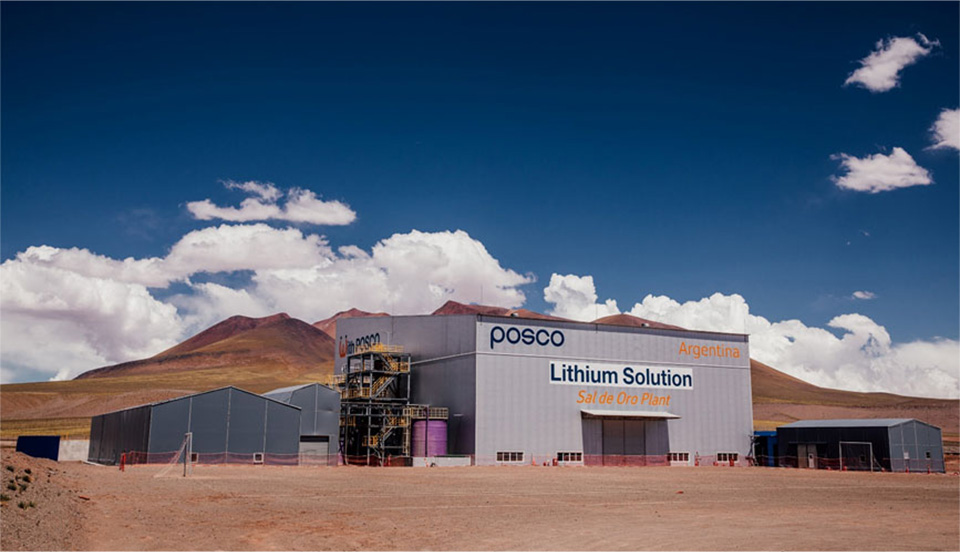

A commercial lithium brine plant is currently under construction in Argentina, aiming for completion in the first half of 2024. The first phase plant, with a capacity of 25,000 tons, is being built for upstream and downstream processes. In addition, construction of the second phase plant, also with a capacity of 25,000 tons, began in June last year. POSCO Group plans to transform the lithium carbonate generated in the second phase upstream process into lithium hydroxide in the subsequent downstream process at the Yulchon 1 Industrial Complex in Gwangyang, and supply it as a material for rechargeable battery cathodes.

▲Chairman Choi Jeong-woo and other guests are conducting a trial run at the groundbreaking ceremony for the first phase of the saltwater lithium project in Hombre Muerto Salt Lake, Argentina, on March 23, 2022. From the left, Byeong-ok Yoo (Vice President), head of POSCO Holdings’ eco-friendly future materials team, Ariel Schale, Federal Vice Minister for Industry at the Ministry of Production, Gustavo Saenz, Governor of Salta, Chairman Jeong-Woo Choi, Raul Jalil, Governor of Catamarca, Myeong-Soo Jang, Korean Ambassador to Argentina, Gwangbok Kim, CEO of POSCO Argentina.

▲POSCO Holdings held a groundbreaking ceremony for the second phase of the brine lithium upstream well at the Hombre Muerto salt lake in Argentina on June 28 (local time), and attendees are conducting a trial run. From the left, POSCO Argentina CEO Kim Kwang-bok, Federal Vice Minister for Industry José Ignacio, Korean Ambassador to Argentina Lee Yong-soo, Salta Governor Gustavo Sáenz, Yoo Byeong-ok, POSCO Holdings Vice President of Eco-friendly Future Materials, and Raúl Jalil. Governor of Catamarca and Federal Deputy Minister of Mining and Industry Fernanda Ávila.

POSCO intends to integrate the third and fourth phases into a 50,000-ton capacity to establish a 100,000-ton lithium production system from Argentine lithium brine by early 2028. The goal is to increase lithium self-sufficiency by extracting lithium from various sources such as brine, ore, and unconventional resources.

▲Overview of the saltwater lithium demo plant in Argentina.

In particular, for the second phase of lithium brine, POSCO plans to establish the upstream process in Argentina and the downstream process in South Korea. This will enable the timely supply of lithium to domestic cathode material plants such as POSCO FUTURE M and gain an advantageous position in the U.S. with the Inflation Reduction Act (IRA).

POSCO Group plans to cooperate with local partners and develop technologies for unconventional lithium resources, including exploring the lithium clay project in the U.S. and promoting an oil-field brine lithium business with the Invest Alberta Corporation in Canada. It also plans to build a system to produce 70,000 tons of unconventional lithium by 2030 and expand lithium production through recycling! Please support POSCO Group in all its efforts!