The elaborate finishing touches of all metal products from smartphones to automobiles are handled through metal molding processes. The metallic mold technology is a framing technique that forms the shape of metal products. With the advancement of machine industry and growing consumer demand for high-quality finished goods, increasing number of superior processing technology is required.

One of the key ingredients of a sophisticated mold processing is the molding plate, which is a flat material used in mold making. Since 2014, POSCO and Shinjin ESCO have been leading the high-end mold plate market based on solid cooperation. We introduce broad ventures from technical cooperation to comprehensive all-round solution marketing activities with Shinjin ESCO.

ㅣQuality Improvement and Cost Reduction through Breakthrough Cutting Technology

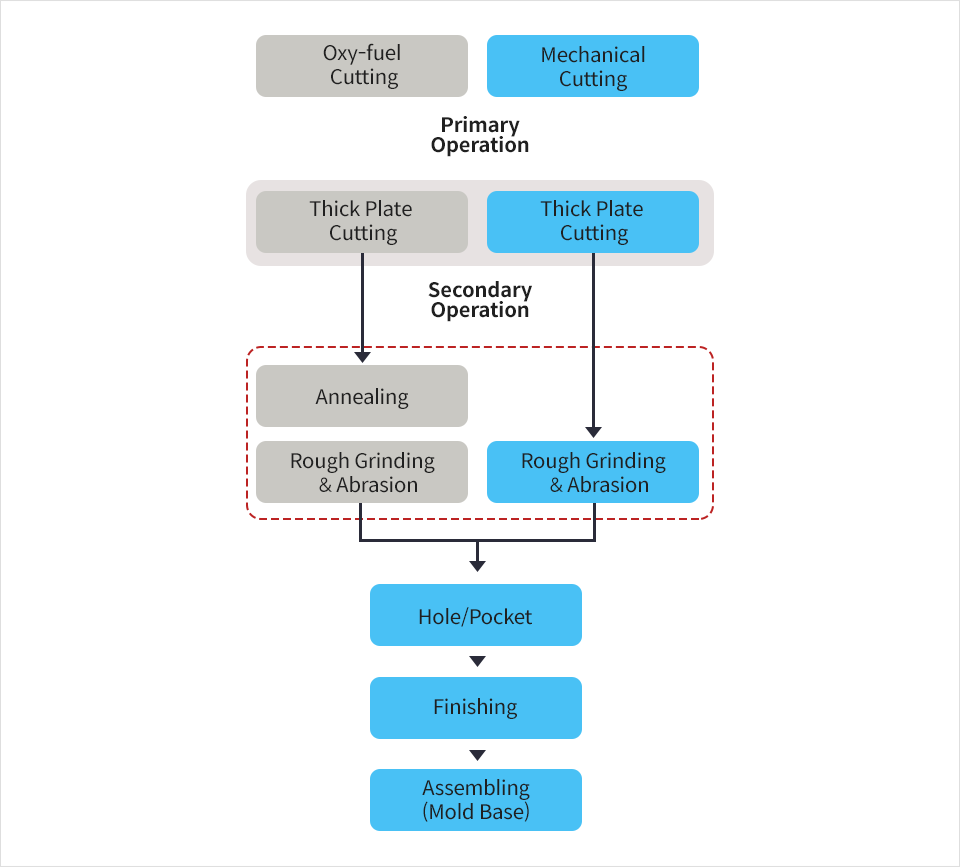

Previously, there were neither a particular technology nor specialized manufacturers in the cutting equipment market for mold plate production. Most small and medium-sized retailers practiced oxy-fuel cutting method. It was the mechanical high-speed cutting technology brought about by the Circular Saw, jointly developed by POSCO and Shinjin ESCO, that has radically improved the mold plate quality and its processing efficiency.

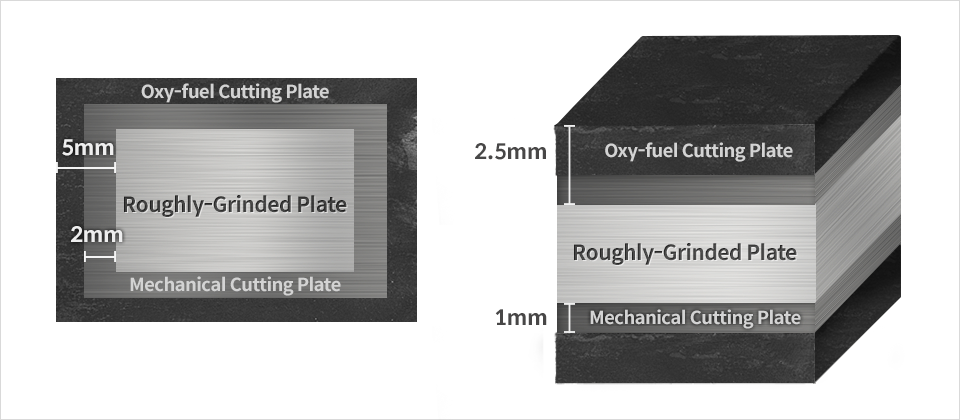

Originally, it was inevitable to perform additional annealing due to oxy-fuel cutting method that has a rough cutting plane and heat treatment on the surface. This also generated the unnecessary loss of plate parts.

POSCO and Shinjin ESCO jointly developed this machine cutting method to resolve these problems once and for all. This machine cutting method enables precise cutting without heat treatment which does not require an additional surface treatment process. Hence, not only is smooth finishing possible, but the optimized procedure and cost reduction also ensue.

ㅣNo to Low-Cost Chinese Products, Yes to Top Quality POSCO Plates

In addition to lack of expertise, low-priced Chinese thick plate imports account for 90% of the domestic mold plate market which explains the sluggish advancement in the domestic mold plate market. No matter how exceptional the processing technology is if the quality of the thick plate is poor, it is difficult to see through the fine design details of the finished product with high degree of perfection. Using solely POSCO thick plates, Shinjin ESCO has a competitive advantage over other mold plate makers.

ㅣPOSCO & Shinjin ESCO Form Win-Win Partnership through Solution Marketing

From technological cooperation to product marketing and sales, POSCO and Shinjin ESCO Solution Marketing has extended far and wide. Most importantly, the thick plate Circular Saw jointly developed by long-term technical cooperation facilitated the advancement of plate mold technology. As POSCO, the manufacturer of thick plates, works directly with the mold plate maker, it allowed the replacement of low-quality Chinese imports with high-quality domestic plates. As a result, Shinjin ESCO is greatly competitive in comparison to other makers, while POSCO is able to secure stable plate retailers.

POSCO and Shinjin ESCO will further solidify their domestic sales target of 15,000 tons of thick plates by 2018. Additionally, POSCO expects to expand its cooperation with Shinjin ESCO, such as securing new importers of technology fee through commercialization of machine cutting technology and entering overseas businesses.