Finalized the deal to supply 1.03 million traction motor cores to Hyundai Motor Group and Kia for their first locally produced EVs in Europe

The is a long-term supply from 2025 to 2034, designated for plants in Turkey and Slovakia

Plant construction in Poland will begin early this year, with further negotiations for global orders from automakers underway

POSCO INTERNATIONAL is broadening its eco-friendly mobility business into Europe.

POSCO INTERNATIONAL (Vice-chairman Jeong Tak) announced on the 18th that it has received an order for 1.03 million units of traction motor core to be installed in Hyundai Motor Company and Kia’s first locally produced electric vehicles (Seltos class) in Europe from 2025 to 2034. Through the electrification plant at Hyundai Mobis’ factory in Slovakia, 550,000 units of traction motor core will be supplied to Hyundai Motor Group and Kia’s Turkish plant, and another 480,000 units will be supplied to the Slovak plant.

With this order, POSCO INTERNATIONAL, together with its subsidiary POSCO Mobility Solutions, has secured contracts to supply a total of 11.87 million units of traction motor core to Hyundai Motor Group and Kia over the past 15 months.

With this order, the company’s plans to build a local production plant in Poland have also gained momentum. Having established an investment corporation in June last year to build a plant in Poland, the company has been advancing its traction motor core business in Europe.

The Polish production plant, which will be the headquarters of POSCO INTERNATIONAL’s traction motor core business in Europe, will be located in Brzeg. Situated near Poland’s southwestern border, the location is adjacent to the production bases of global automakers in Europe, namely in Germany, the Czech Republic, Slovakia, and Hungary, making it a prime spot for local procurement.

The new plant, set to be constructed on a 100,000 ㎡ plot, is due to start construction in the first half of this year with completion expected by the first half of 2025. Upon successful construction, POSCO INTERNATIONAL will be able to produce and supply 1.2 million units of traction motor core annually in Europe by 2030.

The company is consistently developing a global production network to mitigate trade barriers in the electric vehicle market and proactively meet the local procurement requirements of automakers.

By the end of last year, the company had completed a new plant with an annual production capacity of 900,000 units in Suzhou, China. Additionally, in October of the same year, it finished constructing the first traction motor core plant in Mexico and is now considering building a second one in the first half of this year.

Once the Polish plant becomes fully operational, the company will, by 2030, have a global production network in Korea (Pohang, Cheonan), Mexico, Poland, China, and India, thereby achieving a system capable of producing and selling more than 7 million units of traction motor core annually. Through this, the company strategically aims to secure more than 10% of the global market share.

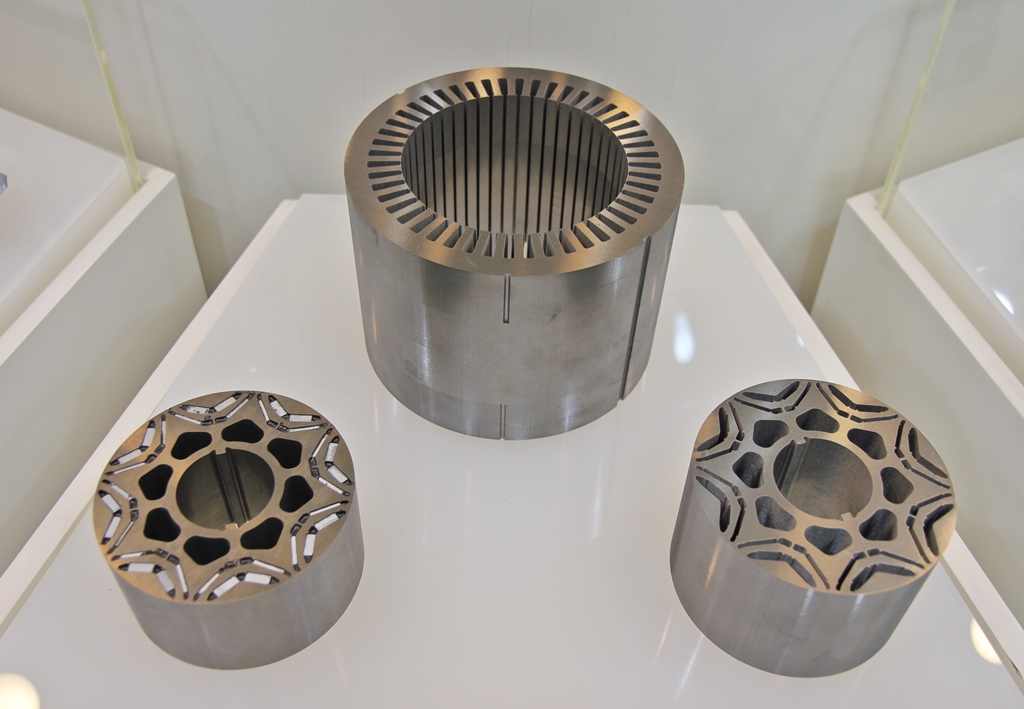

The key to the successful expansion of its business lies in the synergy between the technology and infrastructure provided by its subsidiary, POSCO Mobility Solution, in the mobility sector, and POSCO’s high-quality hyper non-oriented electrical steel (Hyper NO(sup>*), which is a key material used in motor cores.

* Hyper Non-Oriented Electrical Steel: Developed by POSCO, this steel significantly reduces energy loss compared to conventional electrical steel, and POSCO is the only Korean steelmaker that can produce this type of steel.

Established in 2020 as an independent subsidiary of POSCO INTERNATIONAL, POSCO Mobility Solution has become Korea’s top manufacturer of traction motor cores. The patented stacking method developed by its in-house mold research center is considered exceptional for maximizing the efficiency and performance of motors.

“This order is significant because Hyundai Motor Group, a leader in eco-friendly vehicles, will continue to collaborate with us in Europe as well as in the United States,” a POSCO INTERNATIONAL official said. “We will lead the global eco-friendly mobility market through collaboration with major Korean companies in North America and Europe.”