POSCO DX, POSCO Mobility Solutions, and Yaskawa to Deploy Robots in Domestic and International Motor Core Production Plants

POSCO Mobility Solutions Expected to Expand Robot Automation at Domestic, Poland, Mexico, and India Sites

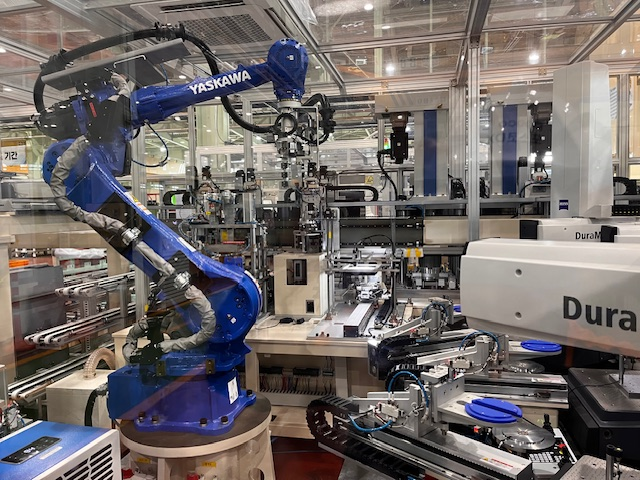

POSCO Group is partnering with Yaskawa Electric (hereafter “Yaskawa”), one of the world’s top three industrial robot manufacturers, to actively expand robot deployment in POSCO Mobility Solutions’ flagship product, the drive motor core production site.

On the 14th, a three-party business agreement signing ceremony was held at POSCO Mobility Solutions’ Cheonan plant. The ceremony was attended by Shim Min-suk, President of POSCO DX; Kim Sang-gyun, President of POSCO Mobility Solutions; and Yamada Seigo, President of Yaskawa Electric Korea, along with other business partners.

Through this collaboration, POSCO Mobility Solutions plans to gradually implement robots that transport motor cores produced by POSCO Mobility Solutions to quality inspection measuring equipment and sort the transported products by quality grade. These robots will be deployed at POSCO Mobility Solutions’ Cheonan and Pohang plants, as well as overseas sites in Poland, Mexico, and India. Prior to this agreement, POSCO Mobility Solutions and POSCO DX had already installed and operated these robots at the Pohang plant last year. POSCO Mobility Solutions expects this collaboration to enhance safety and maximize productivity in industrial sites, laying a solid foundation for future cost competitiveness innovation.

To achieve this, POSCO Mobility Solutions will identify the robot requirements required for production sites, while POSCO DX will design the layout of the robot automation system, considering integration with existing production facilities and systems, and provide and build the entire automation system. Yaskawa will provide the optimized robots and provide technical support, including after-sales service.

The drive motor cores produced by POSCO Mobility Solutions are key components in electric and hybrid vehicles, converting electricity from the battery into rotational power to turn the wheels.

POSCO Mobility Solutions produces drive motor cores and supplies them to global automakers such as Hyundai Motor Company, Tesla, and Stellantis. Yaskawa possesses motion control-based robotics technology in the industrial robotics sector, providing a competitive edge in high-speed, high-precision processes.

A POSCO Group official stated, “We are pursuing productivity improvements by applying robotic automation to industrial sites such as steel and secondary batteries. Through this agreement, we will strengthen our three-way collaboration with Yaskawa, a global robot manufacturer, and expand physical AI-based robotic automation, combined with AI technology, not only within our group but also to external industrial sites.”

Meanwhile, POSCO Group is actively promoting the creation of a safe and comfortable workplace based on technology by expanding intelligent factories across its manufacturing sites to enhance per-person productivity and by applying unmanned robot technology.

▲ A Yaskawa robot is transporting a manufactured product to a quality inspection measuring device at the POSCO Mobility Solutions Pohang Plant’s drive motor core stator production line.