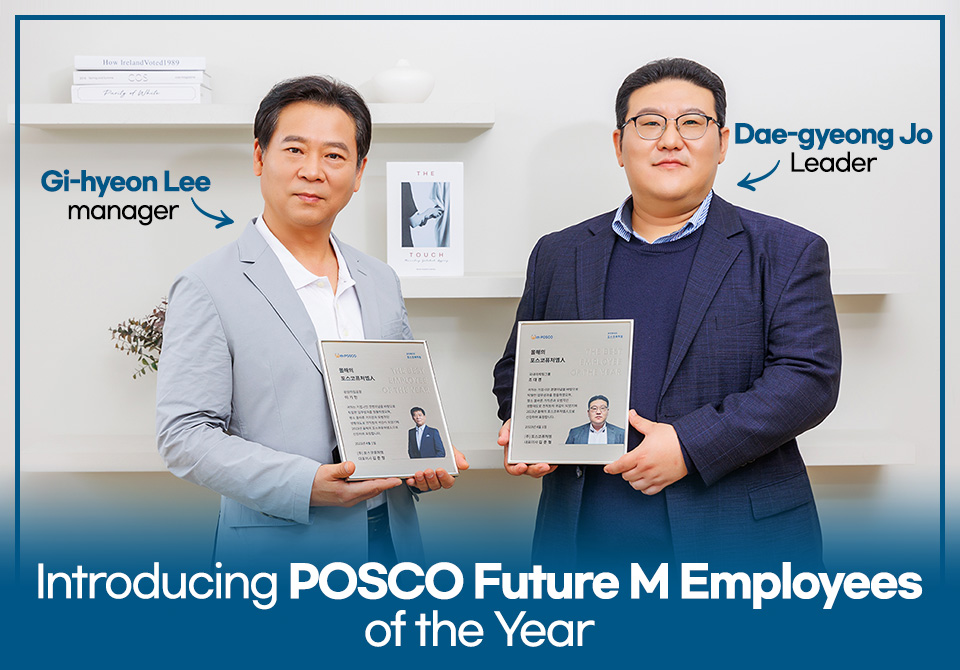

Dae-gyeong Jo, Section Leader

(Domestic Marketing Group of the Energy Material Marketing Office)

Dae-gyeong Jo, Section Leader in the Domestic Marketing Group of the Energy Material Marketing Office, was selected as the POSCO Future Employee of the Year for his contribution to customer diversification by leading a contract to supply cathode materials worth 40 trillion won with Samsung SDI, a domestic battery company.

Q. Please briefly introduce yourself, including details about your work.

Hello! I’m Dae-gyeong Jo from the Domestic Marketing Group of the Energy Material Marketing Office. The Domestic Marketing Group is an organization that forecasts the mid- to long-term market size to promote sales of battery materials such as cathode and anode materials, establishes domestic sales plans accordingly, discusses product sales with customers, and develops new customers.

We work to secure market leadership with POSCO Future M’s material technology and mass production capacity at the forefront of the battery materials business, which is the core of the development of the electric vehicle industry. As a section leader in the Domestic Marketing Group, I am in charge of marketing, such as holding material supply discussions with domestic battery companies such as Samsung SDI, which leads the global electric vehicle battery market.

Q. What is the core goal of the Domestic Marketing Group, and what achievements have you made?

The core goal of the Domestic Marketing Group is to expand the sales volume to customers and the market share based on competitive advantages in the rapidly growing domestic battery materials market. We are strengthening our position in the market by collaborating with domestic battery companies to develop new materials and carry out activities to expand supply.

The Domestic Marketing Group has cooperated with the Battery Material Research Institute, production plants, and process engineering departments to grow sales and steadily diversify its customers since POSCO Future M entered the battery materials business. As a result, we were able to continuously expand the supply of cathode and anode materials to domestic battery companies, and the battery material business accounted for 58.7% of the total sales of 3.3019 trillion won as of 2022, at 1.9383 trillion won.

Recently, we have also been actively engaged in battery material order activities. We signed a contract with LG Energy Solution in April to supply high-nickel NCMA cathode materials worth 30 trillion won. We also agreed to supply high-nickel NCA cathode materials worth 40 trillion won to Samsung SDI in January for 10 years.

Q. What does signing the cathode material supply contract with Samsung SID, which you led, mean for the company?

The contract to supply high-nickel *NCA cathode materials to Samsung SDI is the largest and longest supply contract ever for POSCO Future M, at a scale of 40 trillion won over 10 years. With this contract, POSCO Future M will be able to expand our product portfolio to NCA cathode materials* as well as NCM and NCM (A)*, which has been the main production and supply until now. Furthermore, having secured Samsung SDI, which supplies batteries to various global automakers, as a new customer, we laid the foundation for further significant growth.

*NCA cathode material: Made from lithium, nickel, cobalt, and aluminum Materials that can maximize efficiency due to high energy density and output

*NCM and NCM (A) cathode material: Made from lithium, nickel, cobalt, manganese, and (aluminum) Materials that have advantages in energy density, output, and stability

Q. What difficulties did you face in the contract signing process, and how did you overcome them?

The contract with Samsung SDI is to supply materials for an extended period of 10 years. Since supplying cathode materials worth KRW 40 trillion over 10 years requires continuous investment in expanding production facilities and stable mass production, we had to discuss the matters closely with the departments responsible for production and investment. We also put much effort into building a trust relationship, such as sharing business visions and plans between the two companies to maintain the 10-year business cooperation between the two companies.

We also realized that top management’s commitment was essential when signing the most significant and extended supply contract in the company’s history. We were able to rapidly carry out each stage of the project, such as the development of the NCA product for first mass production, the signing of a supply contract, and the construction of a production line, thanks to the active support of the top management, such as the VP of the Energy Materials Division and the head of the Marketing Office.

Q. How does battery material marketing differ from marketing activities in other industries?

Each customer has different needs for battery materials, so it is essential to supply customized products. Therefore, it is essential to clearly identify the material specifications and performance desired by the customer, examine the possibility of mass production through discussions with the R&D center and production plants, and manage the mass production of final materials.

Since it takes about one and a half to three years from the initial development of battery materials to mass production, we are doing our best to provide optimal services to our customers by constantly considering POSCO Future M’s expansion investment plans, raw material procurement capabilities, and mass production capacity roadmap.

Q. What does the Domestic Marketing Group plan to focus on for the growth of the battery material business?

Battery materials are products of advanced technology. Various technologies are applied at each stage, including core processes such as raw material composition and firing, and mass production. The Domestic Marketing Group aims to develop marketing strategies that highlight the excellence of POSCO Future M’s technology, and to this end, it is strengthening training for employees to cultivate technical marketing capabilities. The plan is to strengthen partnerships with customers based on trust and take early leadership in the market.

Q. Please tell us if you have any plans for the future.

The title POSCO Future M Employee of the Year makes me feel heavy responsibility, but I will do my best as always. Our Group’s goal this year is the quantitative and qualitative expansion of our customers, and I would like to contribute to the development of the battery materials business by actively sharing my know-how with team members.

Gi-hyeon Lee, manager

(Gwangyang Lime Chemical Production Department of the Basic Materials Division)

Gi-hyeon Lee, Manager in the Gwangyang Lime Chemical Production Department of the Basic Materials Division, was selected as POSCO Future M Employee of the Year for his contribution to significantly increasing material productivity through facility strengthening* in the Gwangyang Lime Plant and improving profitability by leading the improvement of the raw material transfer and storage process lines.

*Facility strengthening: Activities to prevent breakdowns or performance degradation and improve facility functions through regular inspection and maintenance of facilities and establishment of emergency response plans

Q. Congratulations on being selected as POSCO Future M Employee of the Year. Please share your thoughts about it.

Being selected as POSCO Future M Employee of the Year is an honor. I just performed the given job silently, and that seems to have achieved results and I received good reviews from my colleagues.

Improving the raw material transfer and storage process line was an essential part of upgrading the Gwangyang Lime Plant, and it is gratifying that my idea of changing the process achieved profitability improvement. Once again, I would like to thank my colleagues for their hard work. I will always try to lead by example to produce POSCO Future M Employee of the Year again at Gwangyang Lime Plant next year.

Q. Which products does the Gwangyang Lime Plant produce, and what is your job there?

The Gwangyang Lime Plant, where I work, produces and supplies burned lime*, which is used as a supplementary raw material to improve the quality of steel products by steel mills such as POSCO. We contribute to the development of the steel industry by producing 3,500 tons of burned lime daily and supplying it to POSCO and others.

My team manages the calcination furnace* that produces burned lime in the plant so that it operates without problems and conducts engineering work to improve plant productivity and product quality.

*Burned lime: A material produced by processing (firing) lime at a high temperature that is used as a supplementary raw material to remove impurities and increase responsiveness in steelmaking processes

*Calcination furnace: A heat treatment facility that uses high-temperature heat and gas to convert raw materials into active materials through a chemical reaction

Q. What do you think is the background and achievements of your selection as POSCO Future M Employee of the Year?

I think I was selected as POSCO Future M Employee of the Year for my contribution to productivity and profitability by enhancing facilities based on my experience and engineering know-how accumulated while working at the Gwangyang Lime Plant for a long time. First, we extended the replacement cycle from 6 months to 2 years by changing the material of the rubber belt that transfers burned lime, which is the final product. It led to an increase in the operating rate of the sintering furnace.

Furthermore, we eliminated manual transportation of limestone, the raw material for burned lime, by improving the raw material transfer and storage process line. Eliminating inefficient tasks, from raw materials to final product production, is critical to increasing plant productivity. Improving the raw material transfer and storage process line was meaningful in that it overcame the inefficiency of unnecessary labor from workers for raw material transportation, and because of this, we achieved an annual profit increase of more than 1 billion won.

Q. What was the reason and driving force behind this achievement?

Our continuous efforts to improve the facilities in the plant have had a significant effect. It is difficult to find a problem if you are stuck with the idea that the plant facilities are currently in optimal condition. My team and I broke away from this inertia and always tried to find problems with the equipment and improve them. The extension of the replacement cycle for run-out belts and the improvement of raw material transfer and storage process lines are all the result of these efforts and considerations.

Q. This is the 33rd year of your service for POSCO. How has your path been for the last 33 years?

I don’t necessarily have any special abilities or know-how. I just worked diligently on my duties daily, and 33 years have passed. I don’t think my long years of service are something to brag about. Anyone with steadfastness and sincerity can achieve it.

Looking back on 33 years, there were so many different things and the joys and sorrows of life, but they are all precious memories. I was happy to be able to walk with POSCO Future M Gwangyang Lime Plant for 33 years, and I would like to work happily and rewarded with my colleagues until the last day I work here.

Q. Why are the processes and process facilities so important to the growth of the basic material business?

The basic material business is not about a process for making new products. it is about stably producing products that are already being made so that there is no hindrance to steel mill production. Therefore, we must manage existing equipment well to use them for a long time without failure.

Also, efforts should be made to improve equipment efficiency so that we can produce more at lower costs. The basic material business can significantly contribute to steel mill operations if we can carry out these activities properly.

Q. To become a POSCO Future M Employee of the Year, the recognition of the members must have been significant. Do you have tips for relationships in the workplace?

I’m one of the oldest shift workers at the plant. Although I am older than other employees, I always try to understand and respect my colleagues. If I try to assert my authority as an elder or senior member at work, my young colleagues will be reluctant to approach me. Everyone, including me, must work to establish an advanced culture that respects each other at all times.

Q. What would you like to tell the junior members who will grow with the company in the future?

You can’t go far if you only look at the results you see in front of you. The most important thing is to set long-term goals you can understand yourself and work steadily to achieve them. The long process of achieving goals can be difficult, but if you faithfully do the work given to you without giving up, you will find yourself growing up at some point.

and do not represent POSCO Future M’s official position of presentation materials.