l One billion POSCO – 46 years after the first drop of molten iron in 1973

l One-billion produces one billion cars and travels to the moon 54 times – back and forth

On October 3, POSCO (CEO Jeong-Woo Choi) achieved one billion tons of crude steel production.

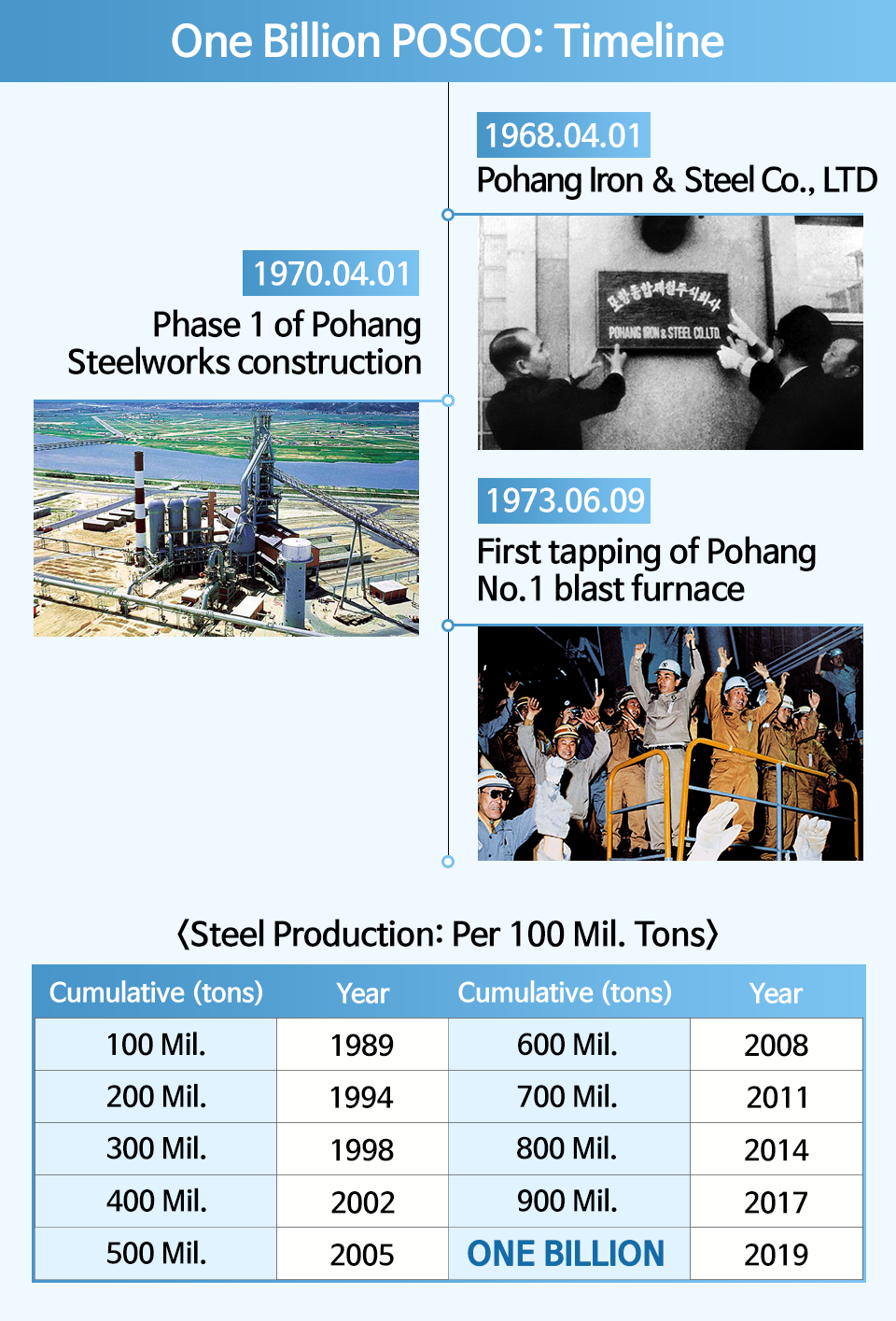

On June 9, 1973, at precisely 7:30 a.m., golden molten iron poured out of the tap of the Pohang No. 1 blast furnace – for the first time. Since that moment POSCO’s blast furnaces have been working tirelessly to produce steel, now at one billion tons.

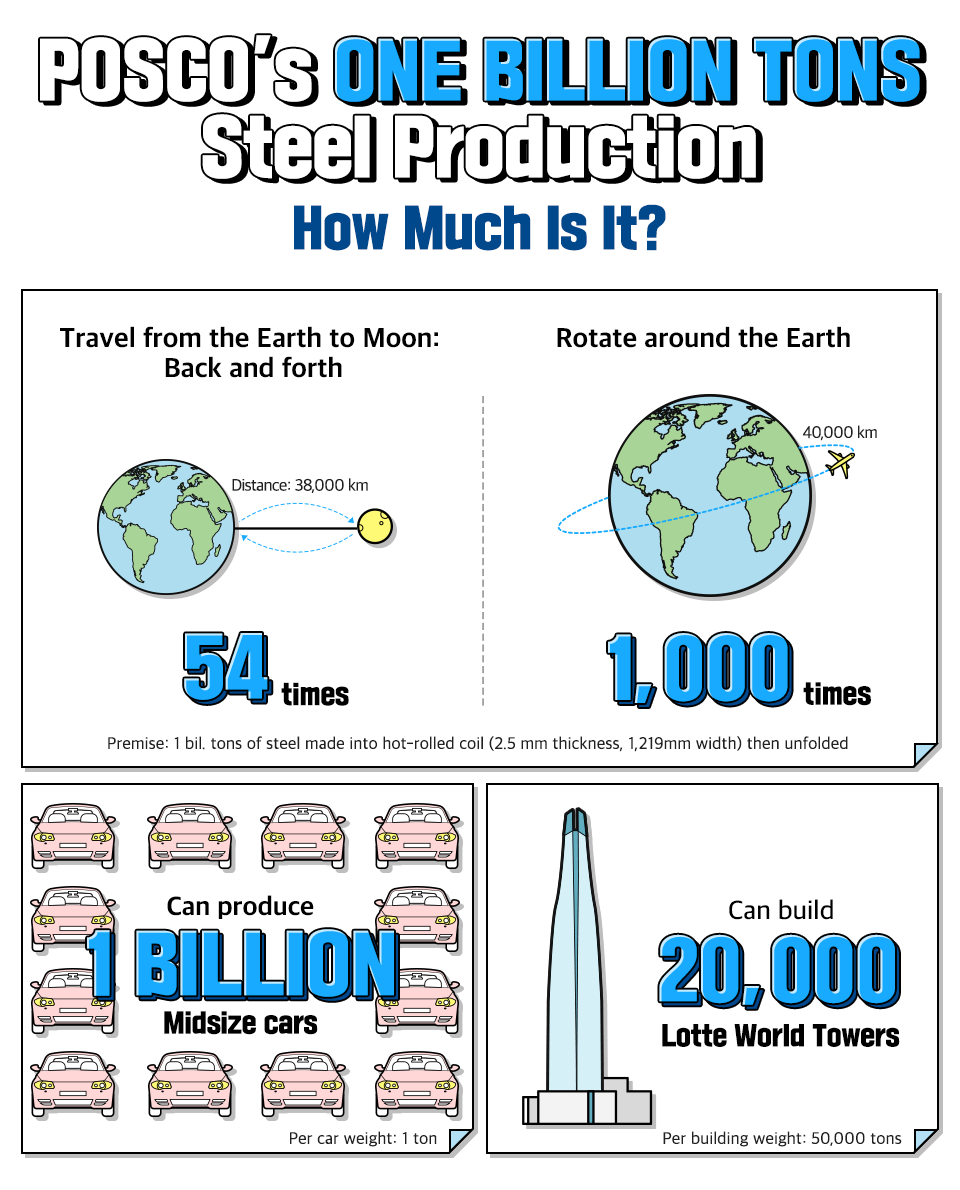

To help gauge the scope of one billion tons of steel, let’s presume there is hot-rolled steel (2.5mm-thick and 1,219 mm width), which will be used as the basis for the calculation. When unfolding the entire one-billion tons of hot-rolled steel of this size, the distance is the equivalent of traveling from the Earth to Moon 54 times – back and forth. One billion tons of steel can also make one billion midsize cars – it can also build 20,000 Lotte World Towers, Korea’s highest skyscraper.

16 years after the first drop of molten iron in 1973, POSCO achieved 100 million tons of crude steel production in January 1989, followed by 500 million tons in 32 years and one billion tons in 46 years.

Through constant technology development and facility calibration, the second half of one billion tons was achieved in just 14 years – the first half took 32 years.

The one billion POSCO could have become a myth had the company slowed down its expansion during the early days. POSCO didn’t – the company’s proactive strategy targeting the global market ultimately bore fruit.

In 1973, the year when the first drop of molten iron poured out of the Pohang No.1 blast furnace, POSCO’s domestic steel production was at 450,000 tons – Korea’s shipbuilding production was at 12,000 CGT (Compensated Gross Tonnage). As for the auto industry, Korea could produce only 25,000 cars per year. As of 2018, with POSCO’s domestic steel production at 37.7 million, Korea’s shipbuilding production soared to 7.7 million CGT and auto production to over 4 million.

As a single steelworks, POSCO’s Gwangyang and Pohang Steelworks is currently the world’s No. 1 and No. 2, respectively. Together, they supply high-quality steel products to domestic and overseas core industries such as high-strength steel for automotive exterior, alloy steel for solar structures, cryogenic high manganese steel, and 9% nickel steel for pressure vessels.

In addition to its top-quality steel products, POSCO provides solutions to optimize the application of the company’s steel products, such as welding and engineering. With its product-technology combo, the company contributed to creating some of Korea’s top landmarks like Incheon International Airport, Lotte World Tower, Incheon Bridge, and large container ships of over 23,000 TEU.

*TEU: Twenty-foot Equivalent Unit is an inexact unit of cargo capacity often used to describe the capacity of container ships and container terminals.

Meanwhile, POSCO has been topping the global ranking for WSD’s ‘World’s Most Competitive Steel Company’ for 10 consecutive years. POSCO’s cost-saving efforts and endless innovation, and sales expansion for the high value-added products all led to world-class competitiveness. Furthermore, POSCO’s establishment of smart factories tailored to the steel industry needs led to a prestigious global recognition as the ‘lighthouse factory’ by the World Economic Forum. The award which designates POSCO as the future of the global manufacturing industry is the first award of its kind for a Korean company.