Often times, the competitiveness of a manufactured product lies in the finishing touches. For centuries, manufacturers have used steel packaging mainly for food, starting with steel cans to package food for the French troops during the Napoleonic wars. Commercial production of steel cans began in 1812 in London to supply longer-lasting food to the British army. Today, manufacturers turn out up to 1000 cans per minute for more than 1500 types of food, but also for beauty products, paints, chemicals and more.

Watch hundreds of steel cans being produced at a Soudronic canning factory.

Advantages of Steel Packaging

Steel is one of the most commonly used packaging materials by manufacturers, because it is widely available, cost-effective and easy to work with. Steel packages can be customized to just about any shape and size depending on the needs of the business, and the continuously improving quality of steel lets manufacturers use less material without losing rigidity.

Steel as a packaging material is tamper-resistant, durable and has an extremely long shelf life, hence the reason why canned food seems to last forever. At the end of its life cycle, steel is 100 percent recyclable and does not lose any of its properties or qualities in the process. Plus, at least 25 percent of every steel can must be made of recycled steel, and its magnetic properties make it even easier to recover for recycling.

Steel is 100 percent recyclable and the most-recycled material in the world. (Source: Causeway Coast and Glens)

According to the Association of European Producers of Steel for Packaging (APEAL), steel packages are the most recycled packages out of all packaging materials, and its recycling rates keep climbing. In Europe, over 77 percent of steel packages are recycled and in countries such as the Netherlands, Belgium and Germany, rates exceed 90 percent.

New Innovations

Today, there are numerous new technologies taking steel packaging to a whole new level. Higher-quality alloys of steel and innovative new methods for processing steel are making everyday products safer, more convenient and efficient. Here’s some examples to show the advances being made in steel packaging.

Bacteria-free stainless steel surfaces

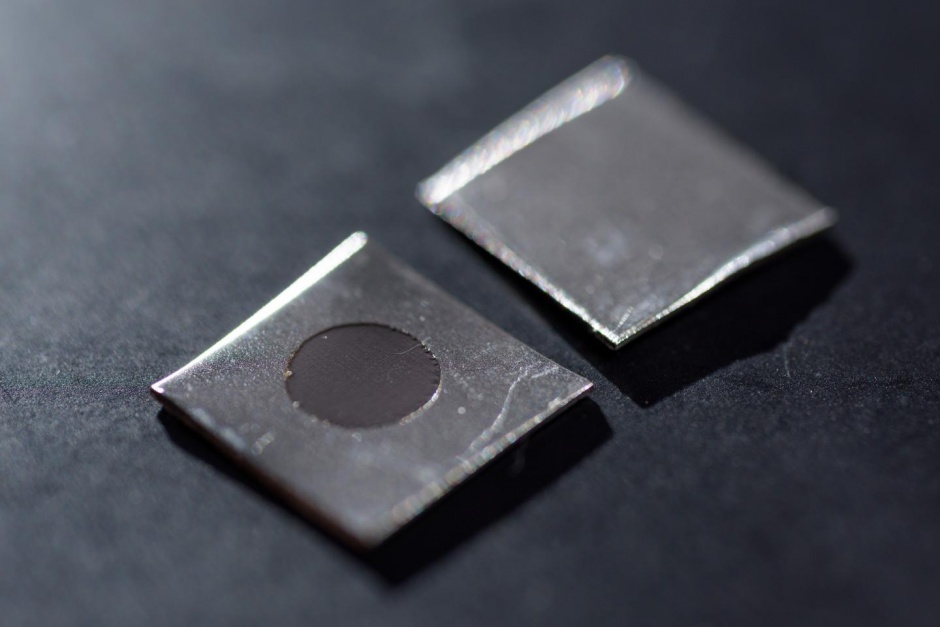

Researchers at Georgia Institute of Technology recently invented a new way to fight harmful bacteria such as E. coli on steel surfaces. Instead of the traditional antibiotics that are temporary and can aid bacteria in developing resistance, this new process uses an electrochemical etching chemical process to create thousands of tiny nano spikes on stainless steel surfaces. By switching up the levels of voltage and current flow in the electrochemical process, the researchers ended up with a rougher, “spiked” surface.

The spikes are about 25 nanometers long, and will kill both gram-positive and gram-negative bacteria on contact, without damaging human cells. The human eye cannot tell the difference between nanotextured steel and regular steel, and the technology increases corrosion resistance as well.

Nanotextured steel can kill bacterial upon contact without harming human cells. (Source: The Engineer)

Though the technology is new and is awaiting additional tests, it could be a permanent solution to treating bacteria and potentially change the medical and food industries completely. Nanotextured stainless steel can be used not only for packaging, but the manufacturing equipment that come in to contact with food. Researchers are also working to apply the technology to spine implants and other implants that come in direct contact with the body.

The world’s lightest 3-piece aerosol can

German company Henkel and packaging manufacturer Ardagh Group developed a new, sustainable aerosol spray can for Henkel’s beauty products using high-quality steel. The can is a mere 0.13mm thick, using up 15 percent less materials than its counterparts, but is also more rigid. The world’s lightest aerosol can also reduce C02 output by 3500 metric tons and water consumption by 900,000 cubic meters per year.

High-quality steel makes this aerosol eco-friendly. (Source: Pack World)

The development is in line with Henkel’s efforts to contribute to a circular economy. Thus the company aimed to design a packaging material that is not only effective and sustainable to produce, but is also 100 percent recyclable.

As the most recycled packaging material in the world, steel will continue to package food, beauty products, paints, chemicals and more manufactured goods. Especially with advances in the quality of steel alloys and innovative ways to process steel, manufacturers can be assured their products will be safe and sound in effective, cost-efficient, sustainable and safe packages.

- aerosol can

- APEAL

- Ardagh Group

- army food

- Association of European Producers of Steel for Packaging

- Bacteria-free stainless steel surfaces

- beauty products

- canned food

- canning factory

- circular economy

- cost-effective

- design

- eco-friendly

- electrochemical

- electrochemical etching chemical

- Georgia Institute of Technology

- Georgia Tech

- Henkel

- High-quality steel

- implants

- material

- military food

- Nanotexture

- Nanotextured

- Nanotextured steel

- Pack World

- Packaging

- packaging manufacturer

- recycling

- resistance

- Safe Packaging

- Soudronic

- Soudronic canning factory

- Soudronic factory

- spikes

- spine implants

- stainless steel

- steel lifecycle

- Steel Packaging

- sustainable

- Sustainable Packaging

- Sustainable Steel Packaging

- technology

- war food

- watch