POSCO Group participated in H2 MEET 2023, South Korea’s largest hydrogen industry exhibition, held from September 13 to 15 at KINTEX in Ilsan. This marks the fourth edition of H2 MEET, which is the country’s premier international exhibition dedicated to the hydrogen industry.

At this event, six POSCO Group companies, including POSCO Holdings, POSCO, POSCO International, POSCO E&C, POSCO Mobility Solution, and the Pohang Research Institute of Industrial Science & Technology (RIST), highlighted the Group’s leadership in the hydrogen industry by collectively showcasing their achievements throughout the hydrogen value chain.

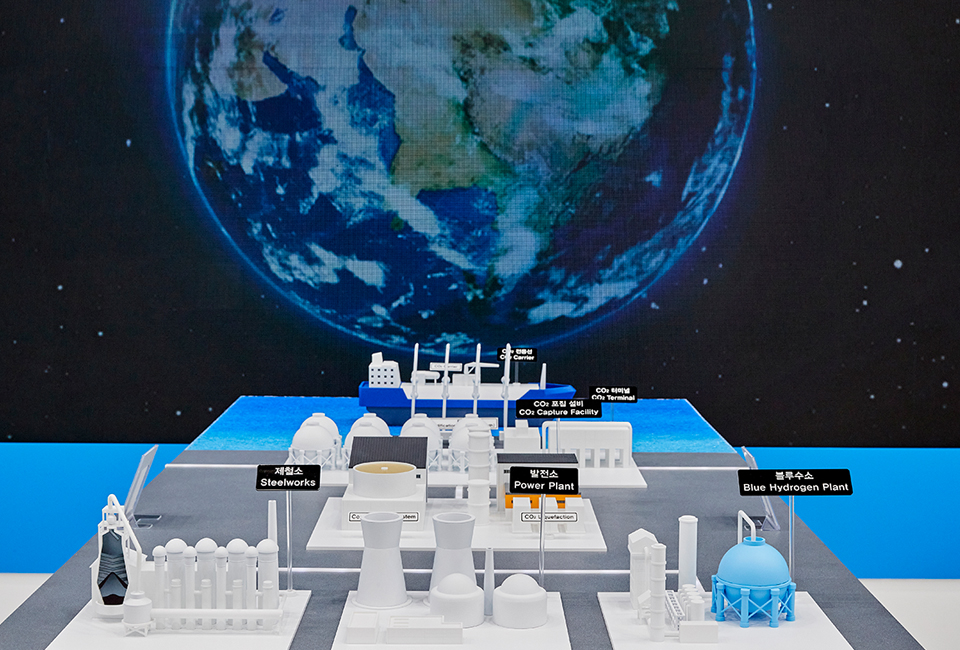

POSCO Group set up exhibition booths with 11 different themes, such as the Global Hydrogen Production Zone, Hydrogen Value Chain Zone, and Hydrogen Production Technology Zone, attracting both domestic and international visitors.

[Global Hydrogen Production Zone]

▲ Visitors are watching a video of the clean hydrogen production project by POSCO Group on the screen in front of the exhibition hall.

The Global Hydrogen Production Zone, which immediately drew the attention of visitors, featured a 3D panoramic video that highlighted POSCO Group’s ongoing clean hydrogen production projects around the world. A large screen on the booth wall brought to life prominent global clean hydrogen initiatives, such as green hydrogen, blue hydrogen, and hydrogen production linked with HBI.

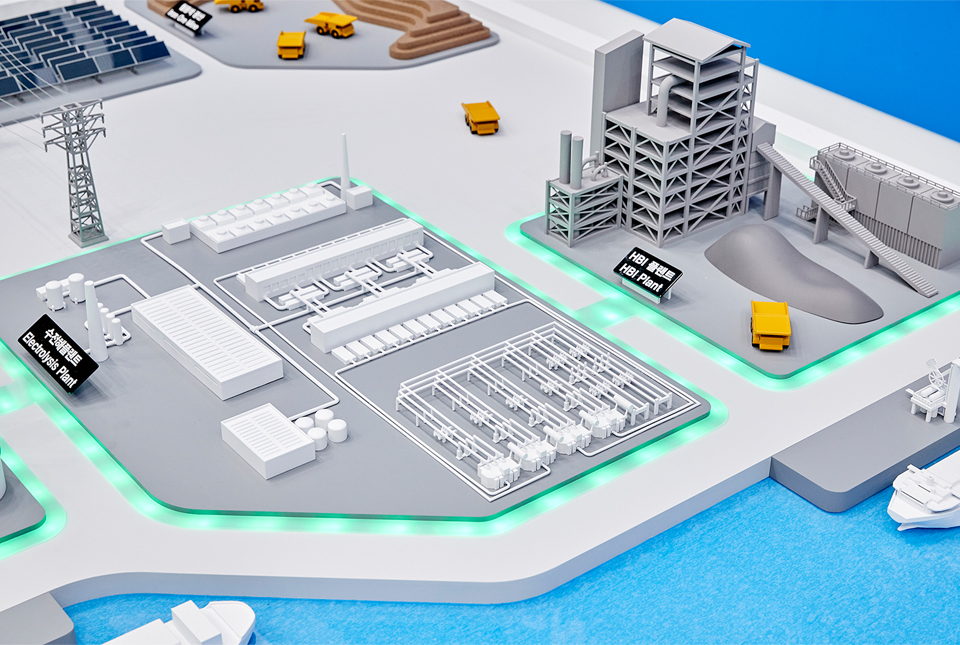

▲ A model displays the scale and production process of Oman’s green hydrogen project.

In front of the large screen was a model of the Oman Green Hydrogen Project. The Oman Green Hydrogen Project is a significant undertaking to establish a 5 GW renewable energy complex and produce 220,000 tons of green hydrogen annually. POSCO Holdings achieved a remarkable feat in June by securing an expansive land area in Oman’s Duqm region, which is equivalent to half the size of Seoul. Hydrogen produced in Oman will be imported to South Korea starting in 2030 for applications in hydrogen reduction steelmaking, power generation, and industrial use.

[Hydrogen Value Chain Zone]

▲ A POSCO Group official in the exhibition hall explains the vision for the hydrogen business.

“Hello! HYDROGEN WORLD” is the first point of entry, where visitors can explore POSCO Group’s hydrogen business value chain. In this space, a visual representation and diagram provide a quick overview of POSCO Group’s vision for hydrogen operations with the establishment of a 7 million-ton hydrogen production system by 2050. POSCO Group’s goal is to become the world’s best hydrogen player by demonstrating its capabilities across the entire hydrogen value chain encompassing materials, infrastructure, storage, transportation, and more.

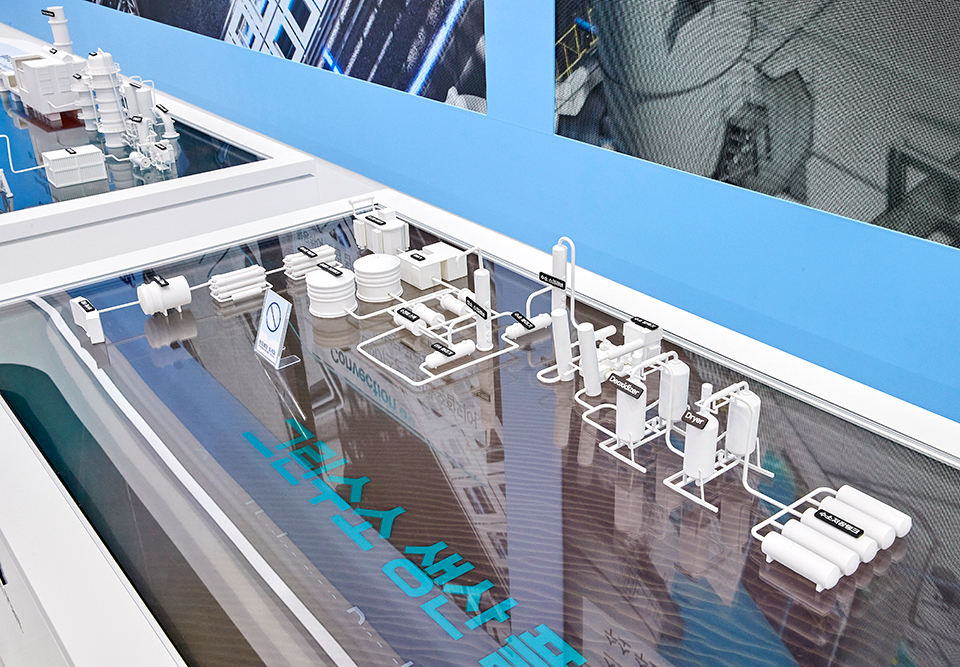

[Hydrogen Production Technology Zone]

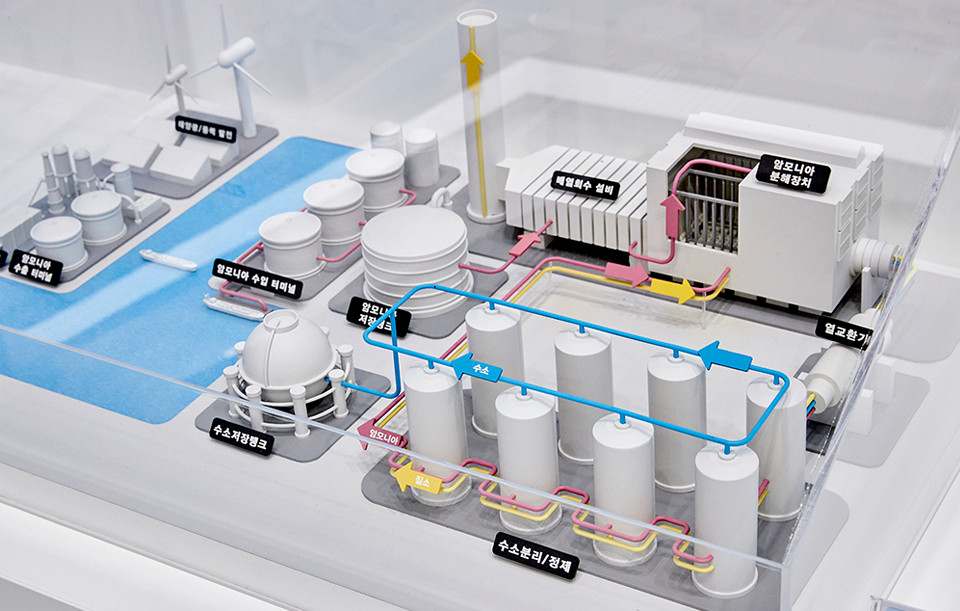

This zone features booths that showcase ammonia-based hydrogen extraction technology, a commercial development effort undertaken in partnership with POSCO Holdings and the RIST. The exhibits include scale models of actual equipment facilities needed for hydrogen production, such as hydrogen storage tanks and ammonia storage tanks, making it easy for visitors to understand the process of hydrogen creation and distribution.

▲ The ammonia-based hydrogen extraction process of POSCO Holdings is implemented in a model.

▲ An official from the exhibition hall is explaining the technology of exporting hydrogen based on ammonia.

Ammonia is attracting attention as an efficient material for storing and transporting green hydrogen due to its high hydrogen content and adaptability to existing infrastructure. In this context, POSCO Holdings plans to complete a demo plant verification by 2025 as the first step in securing commercial ammonia-based hydrogen extraction technology in South Korea.

[Hydrogen Plant EPC Zone]

The Hydrogen Plant EPC Zone by POSCO E&C, which introduces its one-stop capabilities in the hydrogen business covering engineering, procurement, and construction (EPC), is designed to make it easier for visitors to understand the features of green hydrogen and blue hydrogen production plants with 3D visuals and models. POSCO E&C is not only actively involved in large-scale hydrogen initiatives with global partners but has also expressed its ambition to actively contribute to the establishment of carbon neutrality by leading the EPC business in the hydrogen field.

[CCS Zone•Hydrogen Infrastructure Zone•Hydrogen Power Generation Zone]

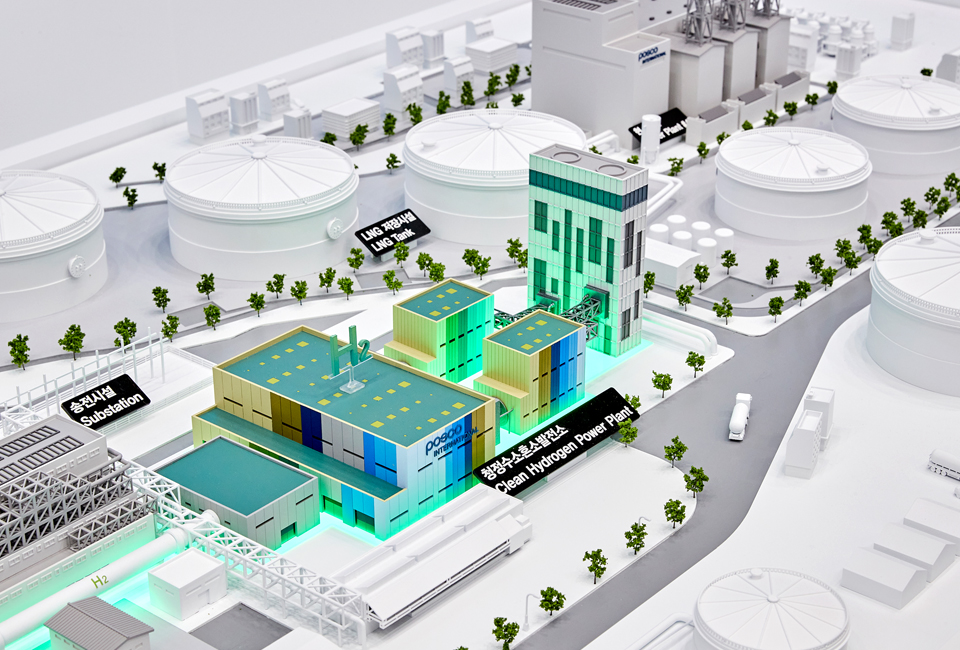

The CCS, Hydrogen Infrastructure, and Power Generation Zones featured POSCO International’s carbon capture and storage (CCS) technology and highlighted the status of domestic projects such as hydrogen composite terminals and hydrogen-blend power generation. POSCO International is conducting global CCS research based on its extensive experience in international resource development projects and is pursuing CCS commercialization efforts in the United States and Australia.

It also plans to build eco-friendly hydrogen composite terminals totaling 1.26 million tons by 2035, mainly in Incheon, Gwangyang, and Pohang, and plans to replace the LNG power plant in Incheon with a gigawatt-scale commercial hydrogen-blend power plant.

[Hydrogen Steel Solution Zone]

The Hydrogen Steel Solution Zone displayed physical objects such as high-manganese steel storage tanks used for hydrogen transportation, mobility fuel tanks, and hydrogen piping, which significantly enhanced the understanding of visitors about the materials and equipment used for the safe and efficient transport of hydrogen. POSCO’s carbon-neutral steel brand Greenate supplies specialized products for hydrogen storage and transportation. These products are evaluated as not only able to safely transport hydrogen but also contribute significantly to securing price competitiveness and localizing materials.

[Mobility Solution Zone]

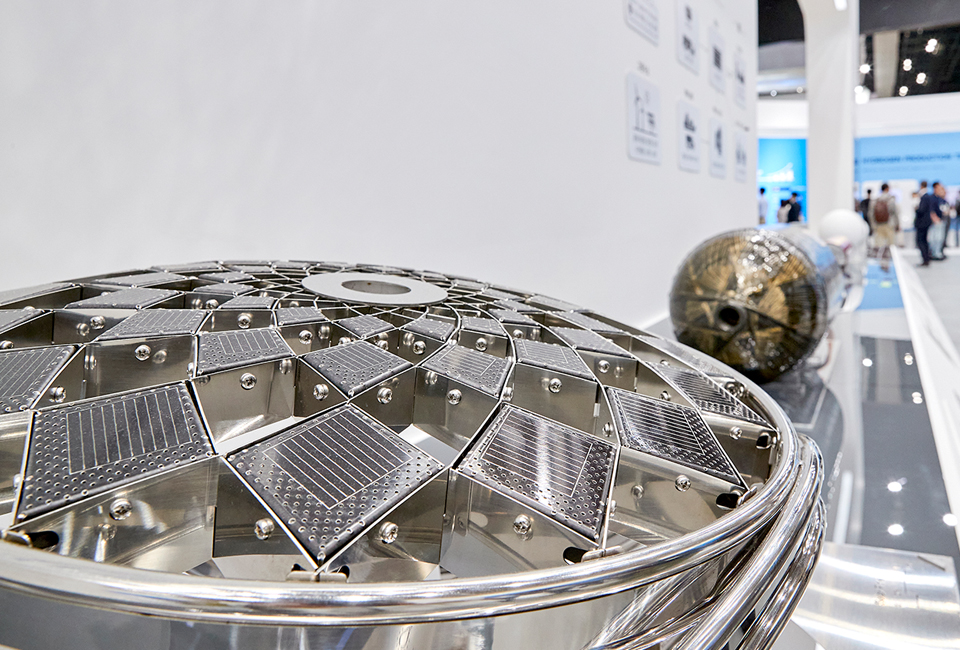

POSCO Mobility Solution produces key components for eco-friendly mobility using POSCO’s steel materials. This zone displayed key components used in various applications, including hydrogen electric vehicle drive/traction motor cores, hybrid vehicle drive/traction motor cores, and hydrogen fuel cell separator plates, for the understanding of visitors.

The drive/traction motor cores stand out for their various stacking technologies and exceptional precision. In particular, the hydrogen fuel cell separator plate “Poss470FC” has attracted attention from the industry as a stainless steel material that secures the highest level of electrical conductivity and economic efficiency by applying the world’s first “coating-free surface treatment” technology.

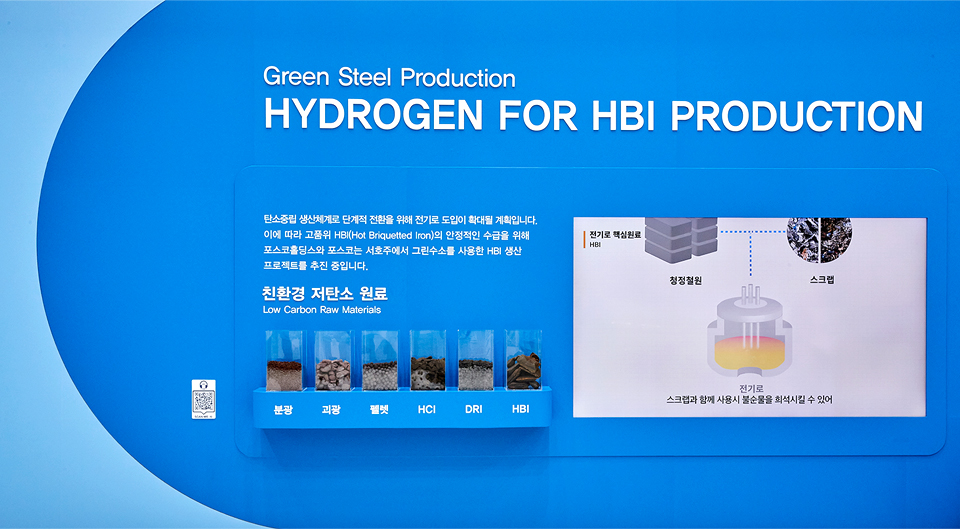

[HBI Zone]

The HBI Zone, a new feature at this year’s H2 MEET event, showcased a hydrogen project linked to HBI, an eco-friendly steel raw material. HBI, is a processed product that is made by removing (reducing) oxygen from iron ore and forming it into a briquette shape. In the HBI Zone, various eco-friendly, low-carbon materials such as HBI, lump ore, fine ore, and pellets were displayed to help visitors understand the hydrogen business.

POSCO announced plans to develop the “hydrogen reduction steel” technology as the ultimate green steel production method. At the same time, the company is adopting electric furnaces as a bridging technology to curtail carbon dioxide emissions. POSCO is set to produce green hydrogen in Australia, a region with abundant iron ore and renewable energy resources, for use as a reducing agent in the production of low-carbon steel raw material, HBI. POSCO is currently advancing projects that include the construction of an HBI plant and the production of green hydrogen in Western Australia.

[HyREX Zone]

The HyREX Zone introduces hydrogen reduction steel, which is the most fundamental reason for POSCO Group’s hydrogen business. POSCO is developing HyREX technology, a hydrogen-based method for making eco-friendly steel without using coal, and aims to have the technology proven by 2030, and operate large-scale commercial plants to achieve carbon neutrality by 2050.

▲ Viewers are listening to a docent explain the Oman Green Hydrogen Project while standing in front of the model.

During the POSCO exhibition, professional docent guides explained the contents of the exhibition in detail to visitors twice a day. These guided tours made it easy for both domestic and international visitors to understand the hydrogen industry and added an engaging element to their exploration of the POSCO exhibition.

POSCO Group is developing key technologies in the hydrogen value chain to secure leadership in the hydrogen business, including ammonia hydrogen extraction, high-temperature steam electrolysis, and carbonate-based blue hydrogen production technology. Ammonia is currently the most efficient means of transporting hydrogen, with 98% of hydrogen business projects worldwide considering ammonia synthesis and transportation methods. POSCO Holdings aims to establish a demonstration plant by 2025 for the development of ammonia hydrogen extraction technology.

High-temperature steam electrolysis is a process that involves electrolyzing steam at temperatures exceeding 700°C. This technology requires minimal electricity, so it is an efficient method for hydrogen production. Efforts are underway to develop the system for commercialization. Lastly, carbonate-based blue hydrogen production is a carbon capture & utilization (CCU) technology that produces sodium bicarbonate (baking soda) by using carbon dioxide and manganese, a byproduct of the steel desulfurization process and Rechargeable battery production. This eco-friendly approach using byproducts is an effective technology to increase the economic viability of blue hydrogen.

In June, POSCO Holdings led a consortium of five companies from three countries to secure the exclusive development rights for the green hydrogen project in Oman, the largest overseas green hydrogen production project undertaken by a South Korean company. The site in the Duqm region of Oman covers an area of 340 square kilometers, equivalent to half the size of Seoul. The plan is to create a 5 GW renewable energy complex on this site with the goal of producing 220,000 tons of green hydrogen annually by 2030. Locally produced green hydrogen will be converted into about 1.2 million tons of ammonia for efficient and safe transportation, and will then be imported to South Korea for use in hydrogen reduction steelmaking, hydrogen-blend power generation, and other applications. Some of the production will also be supplied locally in Oman.

In recent times, the government has been making efforts to create the world’s first large-scale hydrogen demand market by implementing clean hydrogen power generation bidding systems, among other initiatives. POSCO Group needs about 5 million tons of hydrogen for its own demand for hydrogen-reduced steel, hydrogen and ammonia mixed power generation, which is a huge amount equal to about 18% of the domestic demand of 28 million tons by 2050. POSCO Group has a competitive advantage over competitors in achieving economies of scale based on the nation’s largest captive demand. Furthermore, since each group company has expertise throughout the entire hydrogen value chain, significant synergies are anticipated.

Through H2 MEET 2023, POSCO has promoted its differentiated technology and products both domestically and internationally by covering the entire hydrogen business value chain of the Group. The hydrogen business value chain is expected to serve as a driving force not only for Korea but also for the global hydrogen industry as the core of POSCO’s carbon neutrality.