In a world where global dynamics are shifting at an unprecedented pace, what key economic and industrial trends should we focus on today? Experts at the POSCO Research Institute provide in-depth insights into global industries and economic trends, specifically those affecting POSCO Group’s core businesses. Standing at the threshold of a sweeping transformation in the mobility sector, Senior Researcher Gi-Yong Jeon of the POSCO Research Institute takes a closer look at the emerging industries driven by the hyperloop technology and examines how these shifts could reshape the demand for steel.

Senior Researcher Gi-Yong Jeon, POSCO Research Institute

Around the world today, advanced technologies such as artificial intelligence (AI) are converging with sustainability initiatives and redefining the very nature of how we move. In the mobility industry, instead of a supplier-centered perspective based on uniform routes and fixed schedules, a demand-driven model focused on personalized transportation that maximizes mobility is increasingly emphasized. In addition, there are sweeping transformations in the mobility industry in the search for solutions regarding societal challenges such as urban centralization, an aging society, and environmental pollution in connection with the transportation sector. In response, we examine the emerging industrial trends represented by the hyperloop, and analyze how these changes are expected to affect the demand for steel.

I Spotlight on the Future of High-Speed Vacuum Trains: Hyperloop

▲A conceptual diagram of the internal structure of a commercialized Hyperloop. The train runs inside the tube at 1,000 km/h. (Image source: Eurotube Foundation Site(https://eurotube.org))

Elon Musk, CEO of Tesla, recently brought the hyperloop back into the spotlight by mentioning a transatlantic tunnel project on X (formerly Twitter). He suggested that with a $20 billion investment, it would be possible to build an underwater link connecting New York and London. If an underwater hyperloop transportation system is built, passengers could travel from New York to London in under 60 minutes.

The idea of a transatlantic tunnel connecting the United States and Europe has been floated before, but has never materialized due to severe technical limitations and astronomical costs*. With Musk’s renewed proposal, attention has once again turned toward hyperloop technology, which promises speeds exceeding 1,000 kilometers per hour.

*It is estimated that constructing the tunnel using the same method as the Channel Tunnel, which connects the United Kingdom and France, would require an investment equivalent to the size of the U.S. GDP.

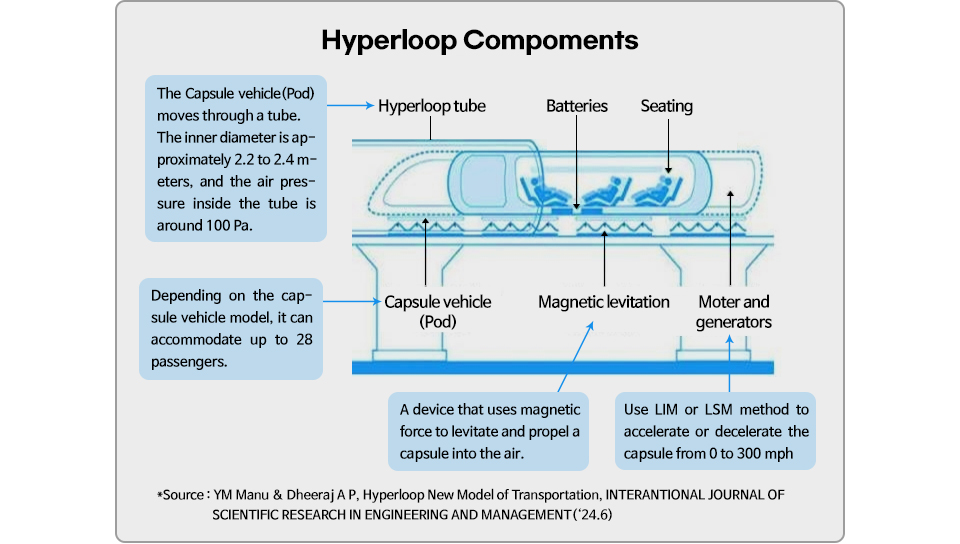

“Hyperloop” is a compound of “hyper” from “hypersonic,” meaning faster than the speed of sound, and “loop,” meaning a circulation ring. It refers to a next-generation high-speed transportation system where capsule-shaped vehicles travel inside a vacuum tube. The hyperloop consists of fully sealed vacuum tubes, passenger capsules, and tracks responsible for propulsion and levitation, and the capsule can travel at speeds over 1,000 km/h in the tube.

To minimize air resistance* at these high speeds, the internal pressure of the tube must be reduced to about 1/1,000th of atmospheric pressure (a near-vacuum). In addition, linear motor propulsion devices must be used for the capsules to levitate by magnetic levitation systems. There are two types of linear motor propulsion: linear induction motor (LIM) or linear synchronous motor (LSM). The LIM system is relatively easy to install and cost-effective for infrastructure, and is mainly used in medium-to-low speed maglev trains such as Linimo in Japan. By contrast, the infrastructure of the LSM system is more expensive but it has a stable power supply even at high speeds, making it suitable for ultra-high-speed trains such as EU HARDT and Japan’s Chuo Shinkansen.

*Air resistance at 200 km/h is four times greater than at 100 km/h, so the tube’s internal pressure must be about 1/1,000th of atmospheric pressure.

For the hyperloop to become a practical mode of transportation, it must first secure both safety and economic feasibility. Because the system must maintain a near-vacuum environment while traveling at high speeds, the stability of the train is critical. The tubes that form the hyperloop tracks must withstand not only their own weight, but also the weight of the capsules, the shocks from high-speed travel, thermal expansion, and atmospheric pressure.

Moreover, as the gap between the capsule and the tube narrows and the capsule approaches the speed of sound, a phenomenon known as the Kantrowitz limit, where airflow inside the tube becomes blocked, may occur. To overcome this issue, it requires securing sufficient clearance by enlarging the diameter of the tube. This demands the development and supply of materials that not only prevent deformation and damage at connection points but also offer excellent airtightness, workability, and economic efficiency. Examples of such materials include PosLoop355 developed by POSCO, and ASTM A1018 Grade 36 steel by AK Steel.

▲A 2.5m diameter hyperloop tube being manufactured by SeAH Steel using POSCO Special Steel PosLoop355.

In underground tunnel sections, ultra-high-density concrete tubes are being considered as an alternative to steel pipes, and ultra-high-performance concrete tubes, such as Hypercrete, are already under development.

I How Close Is Hyperloop to Commercialization?

Considering the demonstration testing plans of hyperloop manufacturers and the conditions needed to secure economic feasibility, the commercialization of Hyperloop is expected to occur after 2030. Countries around the world are building and testing pilot tracks to develop hyperloop technology. The achievements of leading companies are as follows:

[Hardt Hyperloop]

Hardt Hyperloop, a Netherlands-based hyperloop development company, has established the European Hyperloop Center (in Veendam, Groningen Province, Netherlands) and is actively conducting technology development and testing. It plans to build commercial hyperloop lines in the Netherlands and Canada after 2030.

▲A view of the European Hyperloop Center test line using POSCO steel. The 420m-long hyperloop test line, which is scheduled to be completed in March 2024, includes the world’s first Y-shaped switch that allows for changing tracks while in motion. (Image source: Hardt)

POSCO has collaborated with its Steel Research Laboratories, Steel Solutions Research Laboratories, and Marketing Division to participate in the entire process from design to production of the European Hyperloop Center (EHC). It supplied 352 tons of PosLoop355 steel, a material that is 27% lighter than Hardt’s original design. This material is the world’s first specialized steel for hyperloop tubes and features vibration-damping performance 1.7 times higher than that of conventional steel and superior seismic resistance. Additionally, for high-speed route-switching tests on the pilot track, POSCO also supplied 123 tons of high-grade heavy plates.

▲Inside the hyperloop where the European Hyperloop Center is developing technology. (Image Source : Hardt Hyperloop Linkedin)

Moreover, POSCO International invested in Hardt Hyperloop in 2022 as part of its global new business development strategy, acquiring a 6.1% equity stake and securing supply rights for steel materials. In 2023, it further strengthened its relationship by signing a strategic cooperation agreement to collaborate on projects in Europe and the Middle East. POSCO and POSCO International plan to continue promoting POSCO’s steel materials for use in other global hyperloop pilot track projects.

[The Boring Company]

The Boring Company, a U.S.-based transportation infrastructure firm founded by Elon Musk, specializes in the design, construction, and operation of underground tunnels. It is conducting technology verification by building test tracks, designing vacuum tubes, and developing capsule prototypes for hyperloop systems.

[CASIC, China Aerospace Science and industry Corporation]

China Aerospace Science and Industry Corporation (CASIC), a state-owned enterprise, is currently developing a hyperloop system called “T-Flight.” In November 2023, the company completed a 2-kilometer hyperloop test track in Datong, Shanxi Province. However, since trial runs have been conducted only over a relatively short section, additional testing under a variety of conditions remains necessary. During recent trials, the T-Flight system achieved a top speed of 623 kilometers per hour, and CASIC plans to further increase this to 1,000 kilometers per hour in future tests.

In South Korea, there were plans to build a hypertube* demonstration complex in the Saemangeum region and to secure core technologies for its development. However, the project failed to pass the preliminary feasibility assessment conducted in 2023. Momentum for the initiative was reignited in June 2024, when the South Korean government abolished preliminary feasibility evaluations for national research and development projects. Following this decision, the Ministry of Land, Infrastructure, and Transport officially announced on June 9 the launch of research and development efforts for key hypertube technologies, in particular, magnetic levitation and propulsion systems. The government plans to invest a total of KRW 12.7 billion (approximately USD 9.5 million) over the next three years until 2027 to develop four critical technologies: dedicated hypertube tracks, superconducting magnet systems, driving control technologies, and the design and manufacturing of capsule bodies.

*In South Korea, the domestic version of the hyperloop system is referred to as “hypertube.”

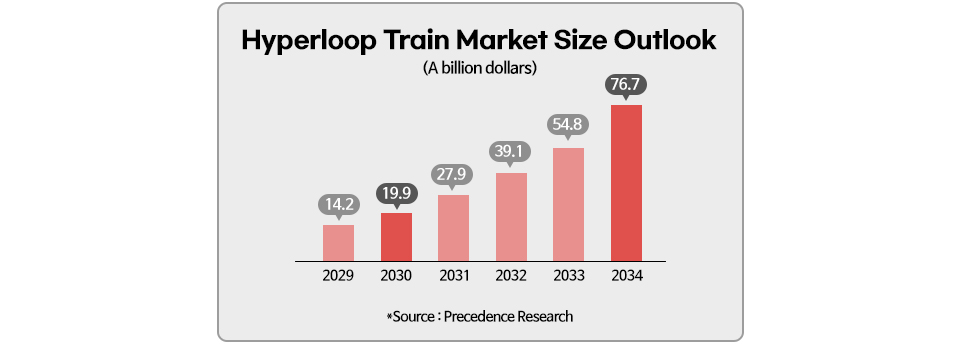

The global hyperloop technology market is experiencing rapid growth. If major countries such as those in Europe replace intercity rail networks with hyperloop systems, the market is projected to reach approximately USD 77 billion by 2034. However, several challenges remain, including the need to develop technologies capable of accommodating the numerous curves found in existing railway routes, as well as the issue of high construction costs. As a result, it is expected that countries such as those in Europe will adopt hyperloop technologies more as a complementary solution rather than as a complete replacement for existing rail infrastructure.

I Steel Industry Sees New Opportunities in Hyperloop, the Next-Generation High-Speed Transport

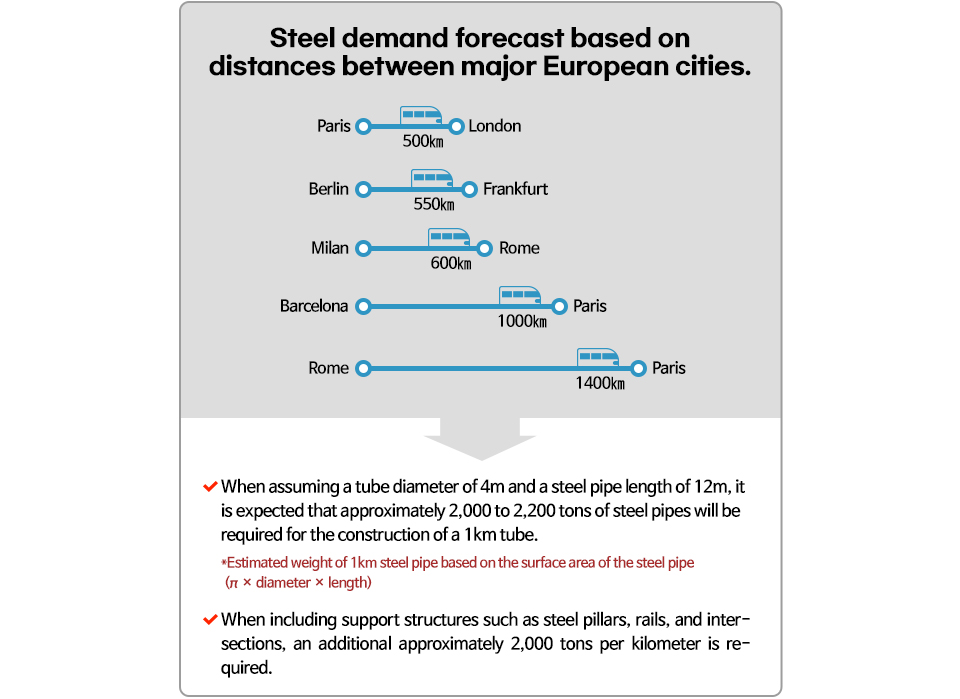

If large-scale infrastructure projects connecting cities with hyperloop systems move forward, it is expected to have a positive impact on the demand for steel. This is because a wide range of infrastructure elements, such as vacuum tubes, intersections, foundational facilities, magnetic levitation systems, and vacuum maintenance systems, will require materials such as steel pipes, structural steel, and stainless steel (STS). The total distance between major cities in Europe is estimated to be around 10,000 kilometers. If these routes were replaced with hyperloop systems, the demand for steel could exceed 20 million tons.

The hyperloop, a next-generation high-speed mode of transportation, presents a significant breakthrough opportunity for the steel industry. To capture future demand in the evolving mobility market, it will be crucial for steelmakers to build stable cooperative networks and continuously develop high-value-added, region-specific steel products tailored to the needs of hyperloop infrastructure.