The changes sweeping across industries around the globe due to advances in technology is one of the hottest topics in business today. Technology is transforming data, breaking down all aspects of traditional industries, a process often referred to as the “Fourth Industrial Revolution.”

Indeed, this topic is so pressing that the theme of January’s World Economic Forum in Davos, Switzerland, was “Mastering the Fourth Industrial Revolution.” Big data, artificial intelligence (AI), virtual reality (VR), 3D printing and the Internet of Things (IoT) are combining to create seismic changes to industry – including to the world of steel.

Just what we mean by the Fourth Industrial Revolution and how that is changing steel were the focus of “The Fourth Industrial Revolution: The Winds of Change Are Blowing in the Steel Industry,” an in-depth essay by Jeho Cheong, senior principal researcher at POSCO Research Institute (POSRI), in the latest issue of POSRI’s Asian Steel Watch.

What Is the Fourth Industrial Revolution?

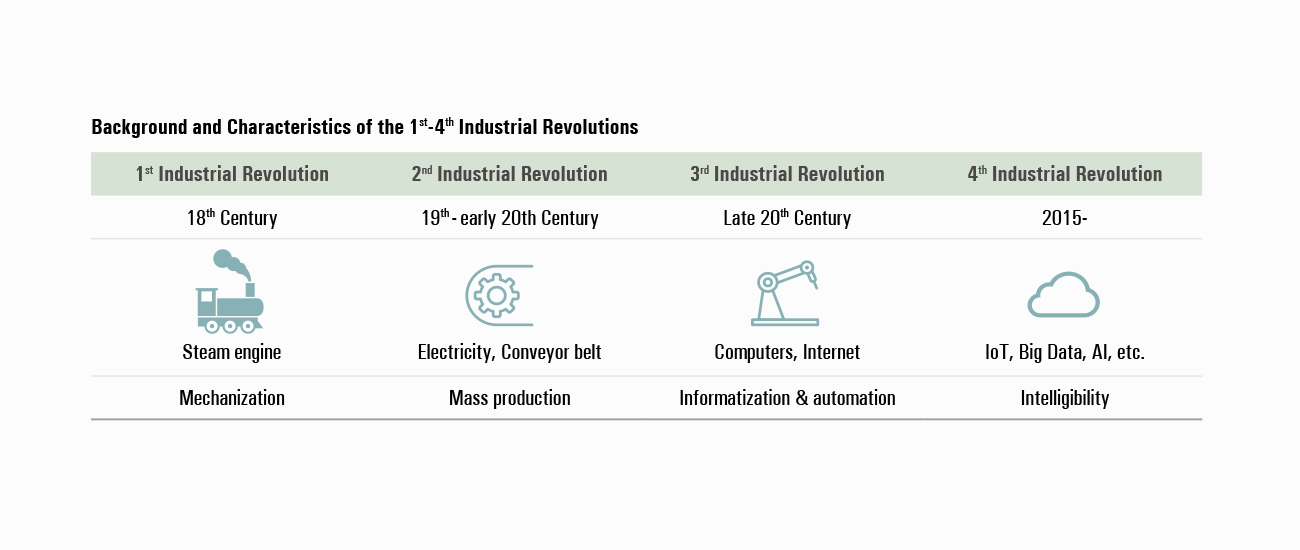

Industry experts and historians have commonly divided up the rise of modern business in industry into a series of significant eras. The original Industrial Revolution refers to the rise of mechanization, most notably the creation of the steam engine.

About a hundred years after that, the spread of electrical power and related technologies (like the conveyor belt) led to the Second Industrial Revolution: mass production. The Third Industrial Revolution appeared in the late-20th century with the rise of computers and the internet, leading to informatization and automation.

The Fourth Industrial Revolution builds on the third, but building in speed, scope and impact to blur the boundaries between the physical, digital and biological. All aspects of knowledge and creation are being combined the smart IT technology to become something exponentially more useful and powerful.

A New Paradigm for Industry

The rise of the Fourth Industrial Revolution is having widespread impact on business, turning many assumptions and practices upside-down. For one thing, the increasing effectiveness of AI technology is threatening many jobs, like in journalism and the financial sectors, where repetitive reports can often be composed by smart algorithms.

This new industrial era also is causing the breakdown of many longstanding business structures. Smart technology is changing how we use energy, how our cars operate and are maintained, and how we pay for goods and services.

But perhaps the biggest change being caused by the Fourth Industrial Revolution is how it is changing value – destroying many traditional sources of value and replacing them with data-driven value. For instance, in the automobile industry, the data about how we drive – where, when, how, etc. – could surpass the value of the cars themselves.

Instead of the economy being primarily about goods, it is becoming about data, and intangible value is exceeding the tangible. The growth of companies like Google, Amazon, and Facebook – modern giants built primarily on data – is a clear sign of how the Fourth Industrial Revolution is changing our world.

What the Fourth Industrial Revolution Means for Business

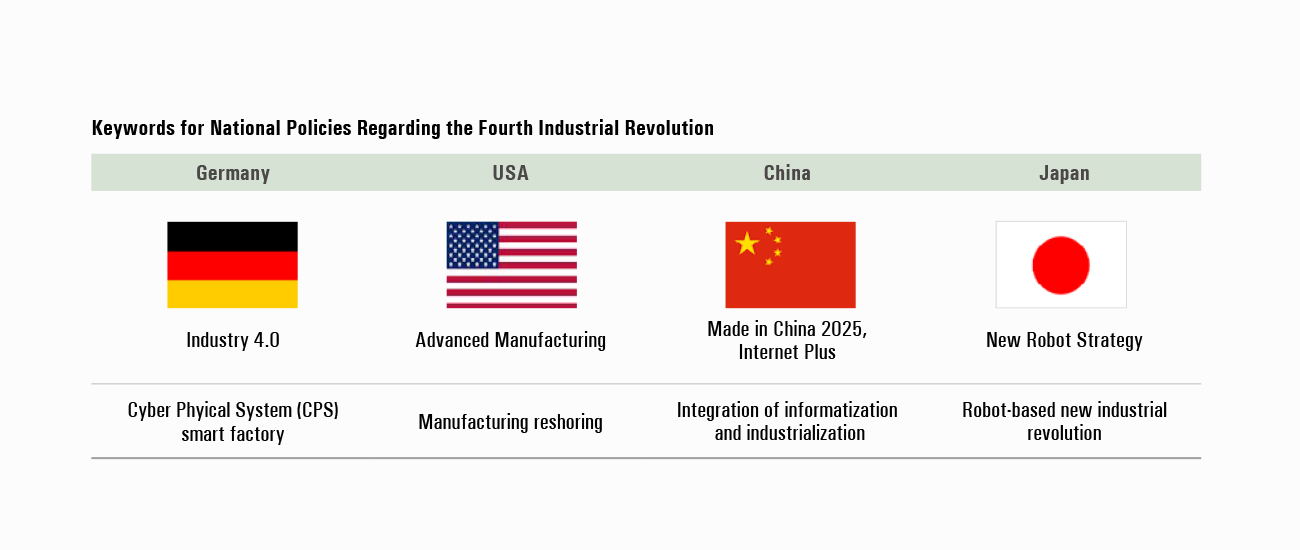

All over the world, governments are teaming up with industry an in attempt to come to terms with these changes. In Germany, they call it “Industry 4.0,” in the United States it is “Advance Manufacturing Partnership,” in China the approaches are “Made in China 2025” and “Internet Plus,” while in Japan it is part of the “New Robot Strategy.”

The nuances and emphases of these approaches are slightly different, but the general idea is the same: to help industry deal with a new, information-based era.

What this means for consumers is increasing customization and personalization. People no longer are content to be part of a large trend. Now they want styles and technologies that work just the way they want to use them. In the past, customization meant huge cost increases, but not anymore.

This in turn is forcing manufacturers to change their entire approach to automation. Instead of central controls and fixed products, now industry is expected to produce dynamic products, constantly reacting to changing situations. Business logistics and manufacturing logistics need to be tightly integrated, to minimize waste and time to market.

Finally, this expansion of value-chains and transformation of manufacturing is changing the nature of service. Where once service was a cost to corporations, today, thanks to better information collection and knowledge of usage patterns, it is becoming a significant revenue source. By using big data, businesses can create valuable information for their customers, which can be monetized and sold.

What the Fourth Industrial Revolution Means for Steel

What do these changes mean for steel? After all, the steel industry is very different than most manufacturing processes: steel requires continuous processing, with liquid steel kept at high temperatures, moving at high speeds. In addition, in the steel-making process, labor is a relatively low cost, so there is little room for automation to bring savings.

But in fact the Fourth Industrial Revolution is bringing big changes to steel, too. These new technologies are allowing steel companies to reduce inventory and grow more flexible and responsive to customer needs. It is possible that all information related to steel supply and demand could become available to all producers and consumers, leading to unprecedented transparency and efficiency.

And at POSCO, the aim is even higher: the creation of a “digital genome map.” Just as the Human Genome Project is sequencing the billions of chemical base pairs that make up the human DNA in order to better diagnose and treat diseases, so too is POSCO working on collecting all microdata about every aspect of steel production.

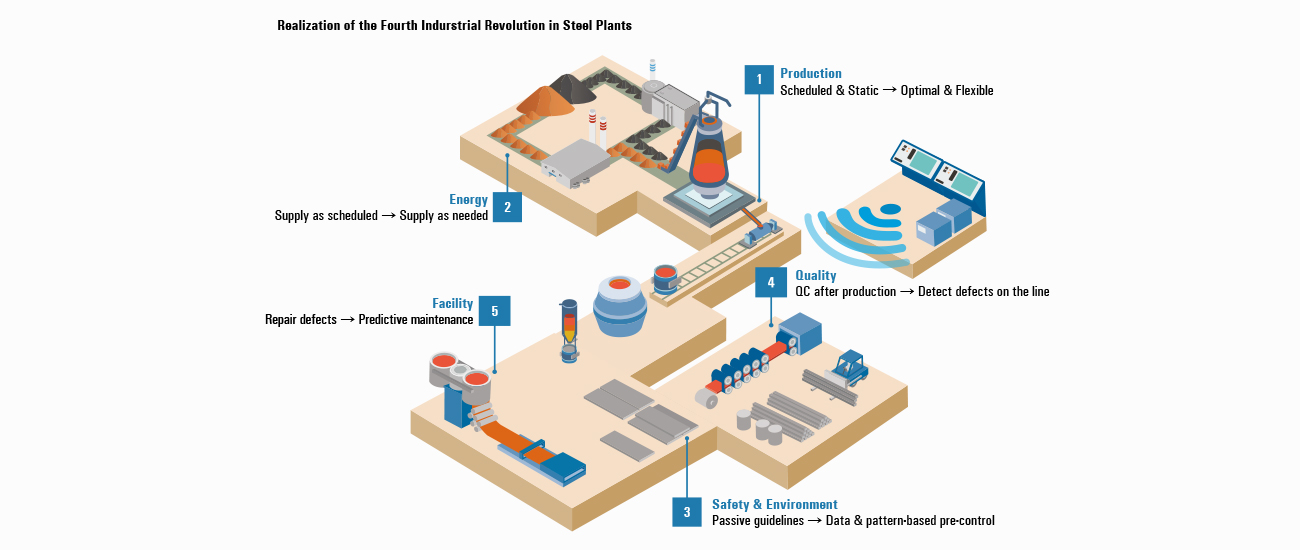

POSCO is looking to create a steel plant that can track every aspect, including production, energy usage, safety, and quality, constantly sensing and responding to inputs. In fact, POSCO’s Gwangyang plate plant is already being turned into a Fourth Industrial Revolution smart factory, and plans are to extend this to all production areas.

The future is just around the corner, and at POSCO, that dedication to innovation is helping to realize the awesome potential of the Fourth Industrial Revolution for the steel industry.