Whether we’re taking a walk in the neighborhoods — surrounded by parks and skyscrapers — or on the road, POSCO technologies are everywhere, but they mostly stay hidden. In episode #3 of ‘Find the Hidden POSCO,’ let’s join Mr. P in his discovery of POSCO technologies around his neighborhood and more! — with POSCO Newsroom.

– Finding the Hidden POSCO!-

Let the POSCO technology treasure hunt begin. Now.

① Higher and Safer with POSCO: HSA, Pos-H, PosMAC

Safe construction of skyscrapers – buildings of 50 floors (200 meters) and up – requires specialized construction technologies. Exponential population growth hence the lack of available lands necessitated more living and working spaces. The demand for skyscrapers is skyrocketing. The building materials must withstand the heavyweight. Not only do we need new technologies that endure added weights, but they should also be prepared for natural disasters like earthquakes and typhoons. POSCO is working on material development and structural systems for higher and safer buildings. POSCO’s signature steel, ‘High-Performance Steel for Architecture’ (HSA), is 1.7 times stronger and 30% lighter than conventional structural materials making them ideal for high-rise buildings. It’s also a seismic reinforcement material that effectively mitigates vibrations transferred to the building in the event of an earthquake. Seoul’s tallest skyscraper Lotte World Tower, Busan LCT, and the Incheon International Airport Terminal 2, and Dongdaegu Station were built with POSCO’s HSA.

POSCO’s other premium construction steel is Pos-H. It’s an exclusive Word Top Premium (WTP) H beam fabricated of POSCO steel plates under POSCO’s strict quality system. Composed of more than 440 available members, Pos-H can be standardized and optimized — compared to conventional rolled H-Beam, it’s cost-efficient needing 15 to 20% less steel for a given component. Pos-H ensures optimum price, delivery, and quality as per customer demands.

The PosMAC-Steel Curtain Wall blocks the external atmosphere without bearing load applied to the building. Consisting of glass and panels attached to steel frames, steel curtain wall provides a highly premium atheistic look. Its high structural performance and good weldability allow the steel to achieve a wide range of designs. A steel curtain wall can be installed for 12 meters and up without reinforcement and can achieve the slimmer design than aluminum. Furthermore, welding PosMAC-Steel Curtain Wall utilizing 3D-Modeling information enables unique design. Compared to aluminum, it provides better performance in terms of structure, heat insulation, flame resistance, anti-seismic capability, and soundproofing.

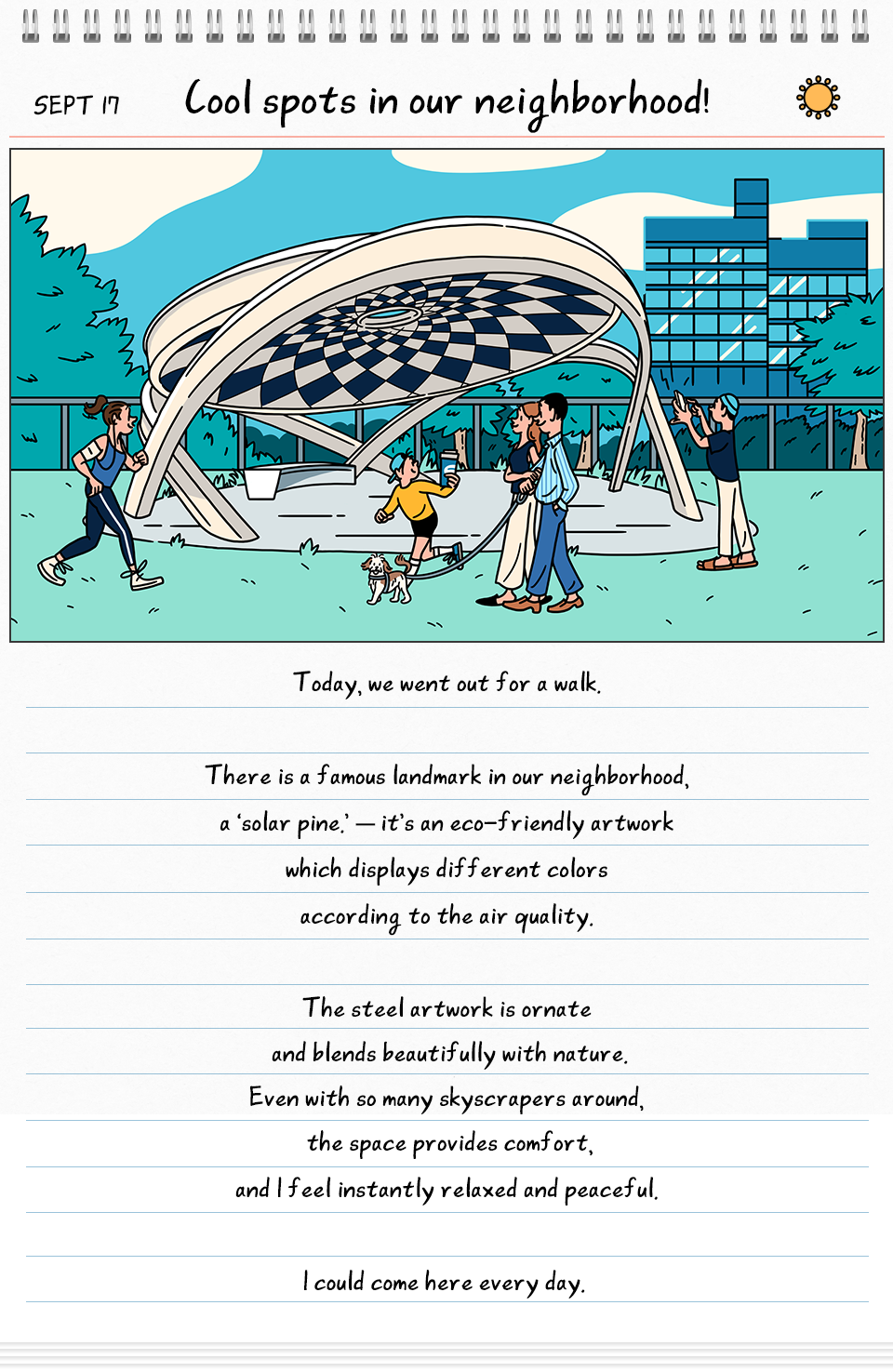

② Eco-Friendly and Vibrant ‘Solar Pine’ — With POSCO

Solar Pine is an eco-friendly solar structure that combines POSCO WTP steel with smart IoT technology. This structure is a sunlight generation sculpture developed by POSCO with its name driving from the geometric pattern and form of a pine cone. POSCO’s technical expertise in Solar Pine isn’t confined to the company’s steel materials — it expands to manufacturing processes such as exterior design and processing. Equipped with 48 solar modules, the circular structure of 5.5 meters in diameter can generate 1kW of power. The upper solar roof creates a geometric shadow pattern during the day. Simultaneously, it also accumulates power through solar power generation, which can be used to charge mobile devices day and night. During winter, it even serves as a warm bench for pedestrians. Solar Pine offers various convenience features such as public Wi-Fi and Bluetooth speakers. Solar Pine can be found at the Seoul Energy Dream Center in Seoul, and POSCO Energy Green Park in Incheon.

③ Think Environment, Think Health with Stainless Travel Mugs and Straws

Outside and thirsty during hot summer? Stainless is the way to go. Environment concerns surrounding disposable plastic cups and straws are drawing attention to alternative materials like stainless steel travel mugs and straws. Not only are they environmentally sustainable, but they also have other features. Notably hygienic, stainless steel is odor-resistant and prevents bacterial growth. Also, with stainless steel, discoloration is rare. Since travel mugs are in constant contact with liquids, they should be rust-free and hygienic. Stainless steel is one of the best materials that meet those requirements.

On average, a plastic straw is used for about 20 minutes but takes 500 years to decompose. Every day, each person uses 1.6 straws. Plastic straws need an urgent replacement. Across the globe, stainless steel is rapidly becoming the go-to material to replace plastics. Unlike plastic straws, stainless steel straws are clean, harm-free, and can be reused over and over.

④ POSCO Steel Plate Sustains Long Distance — 18.38km

Ultra-long bridges have over a one-kilometer distance between pylons.

In Incheon Bridge, more than 50,000 tons of POSCO steel were used — including 24,000 tons of high value-added thick plates by POSCO and 3,000 tons of bridge railing steel, also developed by POSCO. The required amount of TMCP (Thermo-Mechanically Controlled Processed), structural steel for bridges, is 3,000 tons. TMCP steel is a high-quality thick plate with excellent weldability. Including TMCP steel, POSCO’s high value-added thick plates were mainly used for cable-stayed Incheon Bridge. The connectivity bridges of the Bridge are being constructed as concrete bridges for which POSCO’s general steels, including PC stranded wire, were used.

Meanwhile, the cable, one of the most important components in the ultra-long bridges, supports the bridge by transferring the weight to the top plate to the pylon. POSCO currently produces POSCO wire for Cable, PosCable. POSCO’s steel cable is also applied to ‘hanger,’ a part that connects the cable to the top plate. This particular steel wire is produced by twisting multiple strands of the POSCO wire rod. Extremely sturdy and yet, one steel strand can withstand the weight of a 4.5-ton truck of. Being rust-free, PosCable is perfect for the bridge, which is being built over the ocean, keeping the bridge safe and strong for a long time.

⑤ POSCO Steel in the Incheon Airport

Opened last year, the Terminal 2 of Incheon Airport features ‘Art Port,’ a variety of complex cultural spaces. Known for its excellent architectural aesthetics and comfortable facilities, Terminal 2 also features POSCO’s steel products. The roof panel of the passenger terminal contains POSCO’s WTP stainless steel grade 446M. POSCO’s 446 M stainless steel features maximum corrosion resistance against the airport’s coastal climate utilizing the material’s low thermal expansion — characteristics of the 400 series. POSCO specialty steels were applied to the roof and building exterior materials in offshore or factory areas. For the roof area, the weight of the roof was reduced by applying the POSCO Space System, a joint node technology — one of POSCO’s solution technologies applied to the large-space shell structure. In the main ticketing area, there are large tree-shaped pillars which used HSA800 steel, a for ultra-high-strength structure material. HSA800 helped minimize the column sizes, creating a vast openness in the space. HSA800 can greatly reduce the amount of steel used in large spaces or high-rise constructions.

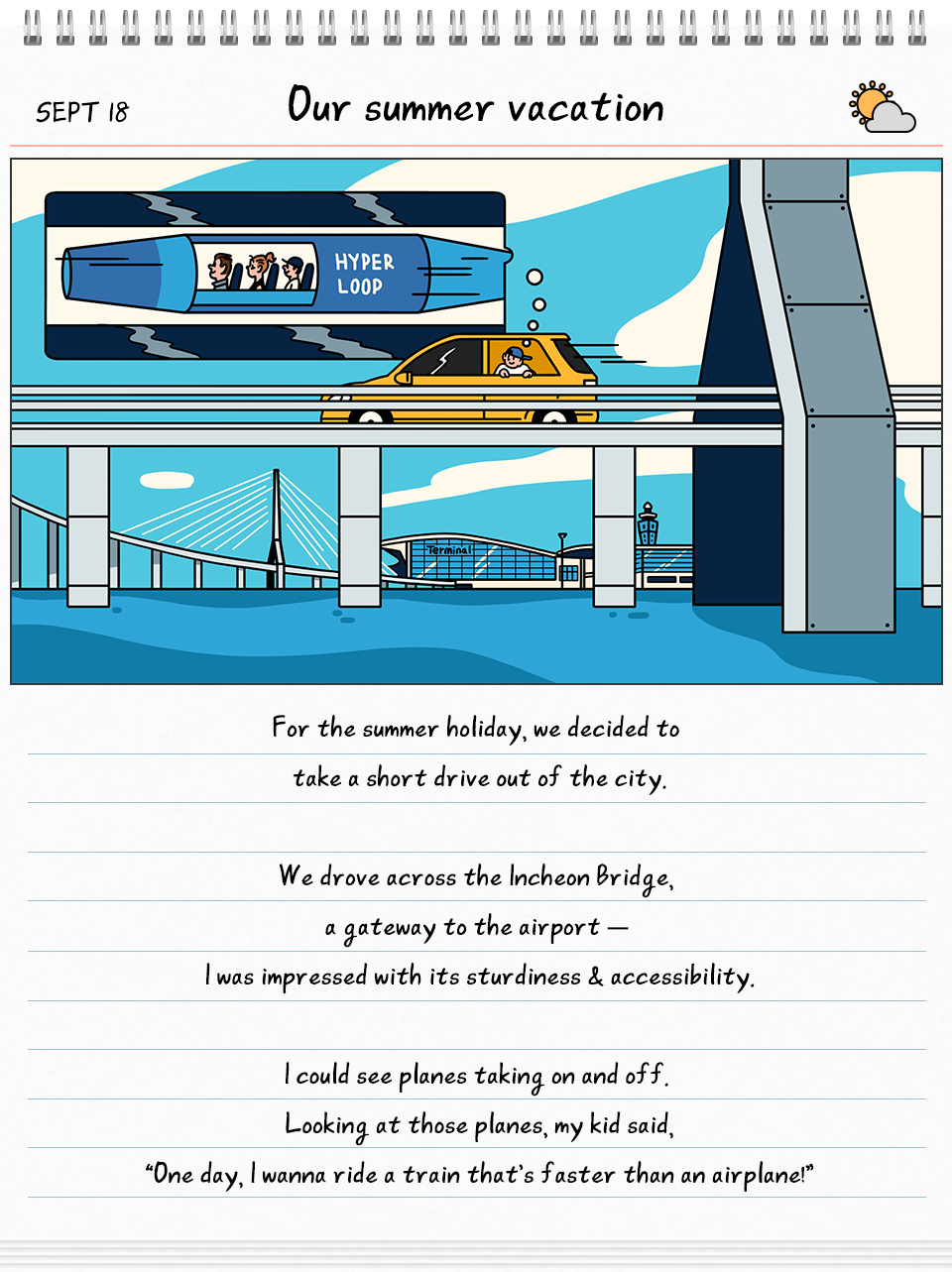

⑥ Hyperloop, Future Mega Trend for Mega City

Hyperloop is drawing attention as a new means of transportation and future megatrend. Hyperloop refers to a train-type transportation system that can run as fast as 1,280 km per hour with close to zero resistance to the vehicle. For the train tube, hyperloop uses POSCO’s high-performance steel, a spiral steel pipe with a diameter of four meters with a thickness of 20-30mm. The material applies specialized high-performance hot rolling, which maintains vacuum in the tubes and propels the vehicle for high-speed operation.

For the hyperloop to work, it must first be connected to an almost vacuum-like low-pressure (0.001 atm) tube — from departure to destination. The vehicle must be supported by an electromagnetic motor while maintaining the vacuum in the tube. Propulsion is achieved by sending air back to the pressurizer. Pressurized air uses air bearings to minimize friction, and solar energy increases efficiency. With Hyperloop, the 400-km travel between Seoul and Busan is expected to take about 20 minutes.

Through the episodes of #1 through #3 of [Find the Hidden POSCO], we discovered the presence of POSCO’s steel and technologies which can be spotted everywhere around us. What new technologies will be added to the current list, and how will they transform our lives? POSCO Newsroom will continue following this journey every step of the way.