In the age of portable electronics, electric cars and robots, secondary batteries — also known as rechargeable batteries — are becoming more relevant than ever, which explains why global companies increasingly identify them as the new growth engine for their business.

Well aware of the crucial importance of secondary batteries, POSCO has been prioritizing the development of core materials for secondary batteries as a new growth business for years. Despite its ubiquitousness, the public remains mostly unfamiliar with the term. POSCO Newsroom reports.

What’s a Secondary Battery? Is There a ‘First’ Battery?

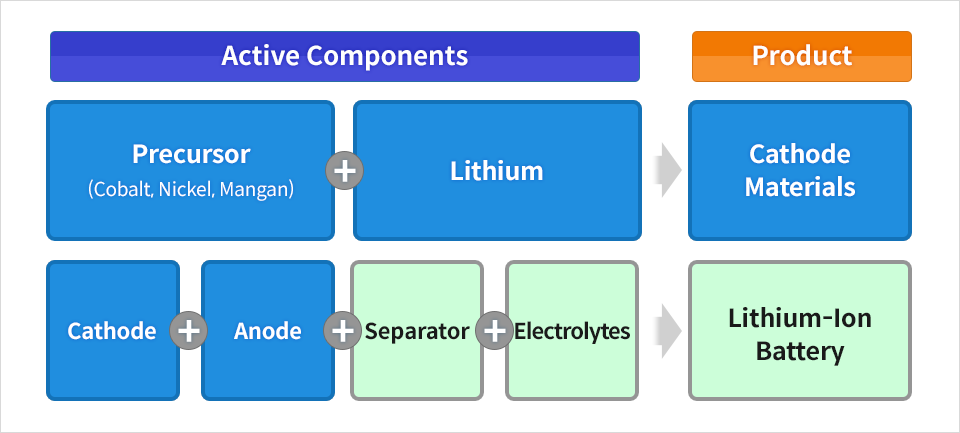

▲Components and the end product of a lithium-ion battery, which is a secondary battery. The areas highlighted in blue are where POSCO is focusing on as new growth areas for the future.

The answer is YES. It’s called primary battery. Simply put, a primary battery is used for clocks, remote controls, etc. Once used up, these batteries can’t be used again — an alkaline battery is the most common type of primary battery.

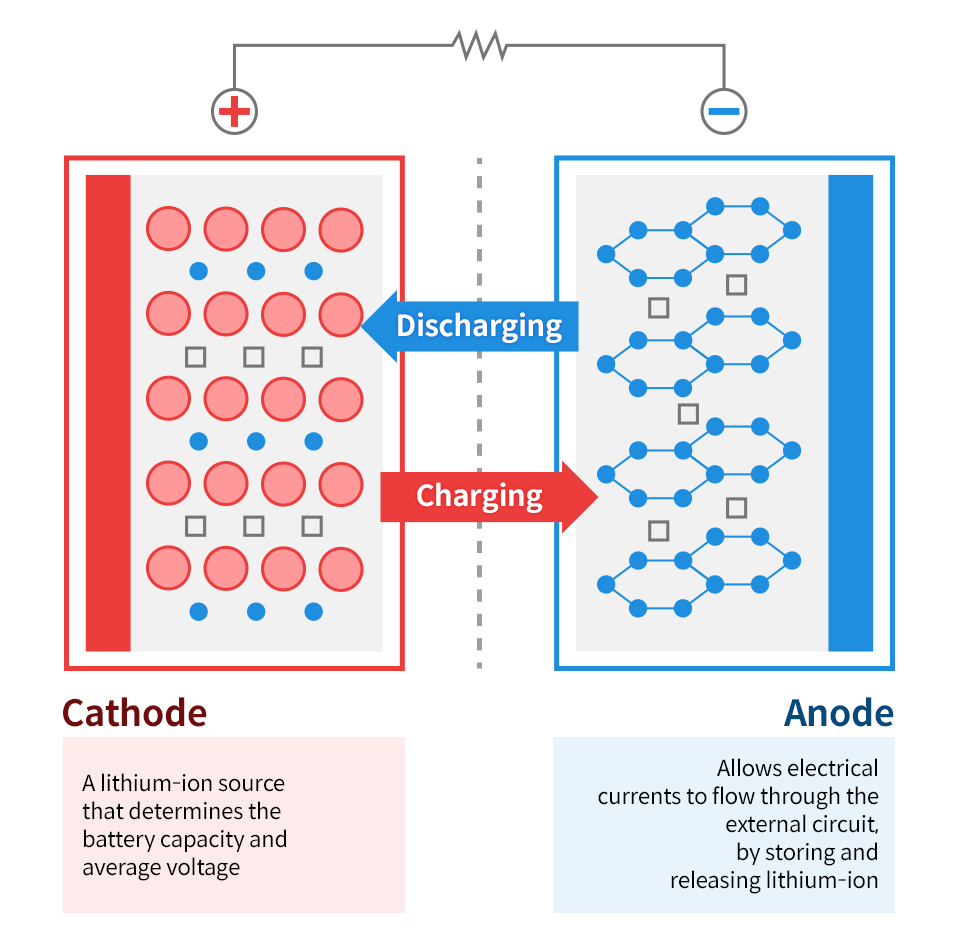

Unlike primary batteries, a secondary battery can be charged repeatedly. It consists of a cathode, anode, electrolytes, and a separator. Electricity is generated through the electrical flow of lithium-ion via electrolytes between cathode and anode material.

When a battery is charging, electrons flow from cathode to anode through the separator. When a battery is discharging, vice versa: electrons flow from anode to cathode. Lithium-ion batteries are one of the most common types of secondary batteries, considered essential for electric vehicles, eco-friendly thus crucial mode of transportation for the future.

What are Cathode and Anode Materials?

▲Anatomy of a Lithium-Ion Battery

Within POSCO Group, POSCO ESM is currently producing cathode materials. Despite its relatively late start, POSCO ESM stands comparison with the world’s top secondary battery active material companies in terms of technology. In recent years, POSCO ESM has become the first company in the world to mass-produce Gradient-NCM active material that contains more than 80% of nickel.

Anode materials generate electricity by storing and releasing the lithium that initially came from the positive terminal. As of now, POSCO ChemTech is the only manufacturer in Korea who mass-produces anode materials. Just this November, POSCO ChemTech completed the construction of the first anode material factory, also wrapping up the first phase of its plan by finishing the first four production lines by the second half of 2019. Through this accomplishment, POSCO ChemTech secured production capacity of 20,000 tons per annum. It plans to further expand to ten production lines, with a view to subsequently boosting the production capacity to 50,000 tons per year.

Earlier this month at its board meeting, POSCO ChemTech agreed on a merge with POSCO ESM for improved synergy between two groups’ energy materials businesses. POSCO ChemTech and POSCO ESM, who are respectively in charge of anode and cathode production, will unify as an operation headquarter for energy materials — bringing together dispersed business structures for cathode and anode materials. The merger between the two groups is expected to crystallize by April next year after the board’s final approval in February 2019.

Through the merger, POSCO ChemTech is set to step up on its effort to develop products that will lead the next generation. The merger will also augment the company’s R & D and marketing capacity, which will in turn help reinforce POSCO ChemTech’s competitiveness by reducing production costs and expanding sales effort.

Lithium-Ion Battery Advantages

As opposed to secondary batteries, primary batteries can’t be reused. Once used up, they should be discarded in which circumstance more resources are wasted to produce new batteries. There is also an additional disadvantage in that chemicals inside primary batteries can incur further environmental pollution. Secondary batteries, on the other hand, can be used for 500 to 2,000 cycles, thus more economical and environmentally sustainable.

Lithium-ion battery, one of the most typical form of second batteries, is known for its durability. Compared to other types of batteries with the same capacity, a lithium-ion battery can be produced in smaller weights and volumes. It also doesn’t carry environmental toxins such as cadmium, lead, and mercury. Furthermore, not only does lithium-ion battery have no memory effect — aka lazy battery effect — that reduces the charge capacity, it also generates more power than regular batteries.

Global Secondary Batteries Market and Where POSCO Stands

▲Production line for cathode material – POSCO ESM Factory in Gumi.

Lithium is an essential material for electric vehicles and energy storage system (ESS). In 2017, the demand for lithium was at 201,000 tons. By 2025, it’s expected to surge threefold, to 700,000 tons.

Lithium has enormous growth potential. POSCO’s endeavor for the last eight years brought them to the early stages of lithium commercialization. In 2010, POSCO became the first developer of a direct extraction technology before any other companies in the world. From 2013 to 2015, it successfully test-produced lithium in Chile and Argentina. In 2016, it built a 2,500-ton demo plant in Gwangyang Works — and since February last year, it’s producing lithium carbonate.

This year, POSCO successfully created lithium hydroxide, which is mainly used for high-performance electric vehicle batteries. POSCO’s accomplishment is especially meaningful because process control for lithium hydroxide is notoriously complicated. With POSCO’s successful localization of lithium hydroxide, Korean companies who had been exclusively relying on imports, can now be supplied with domestically produced high-grade lithium hydroxide, thus boosting the competitiveness of Korea’s lithium secondary battery industry.

┃Lithium: The Core Material for Secondary Batteries

(Source: Flickr)

Amongst all the metals, lithium belongs to the lightest alkali metal with an atomic number of 3, which means it is the third lightest substance in the world.

Recently, lithium is being identified as the rice of the future industry, or the ‘New White Oil’ because the secondary battery has emerged as a future growth industry. In addition to portable electronics like mobile phones and laptops, lithium is garnering industry’s attention as the essential material for making secondary batteries that are crucial for electric vehicles and robotics.

Compared to regular batteries, lithium-based secondary batteries produce higher voltages with less weight. The voltage of a standard battery is at about 1.3 to 2 volts, whereas a lithium-containing battery generates 3-plus volts of electricity. In addition, it is smaller and lighter than other metal ions, resulting in high energy density per unit.

┃POSCO’s Choice for the Future Fuel

▲‘Hombre Muerto’: a salt lake in Northwestern Argentina where POSCO secured the mining rights.

POSCO initially pursued a lithium business project based on a lithium extraction technology — from salt brine, but a delay in securing a salt lake posed as a new challenge. However, POSCO successfully turned this crisis into a unique opportunity, by successfully developing two innovative technologies: producing lithium from discarded secondary batteries, and extracting lithium from the ore lithium concentrate.

In October this year, POSCO also completed a facility with a capacity to manufacture lithium ore. Ore-based lithium production became a reality. From 2021, POSCO will produce lithium from a salt lake in Argentina where POSCO acquired the mining rights.

By securing the world’s only lithium production system utilizing discarded secondary batteries, lithium ore, and salt lake, POSCO is expected to produce a total of 55,000 tons of lithium per year, an amount that can produce batteries for about 1.1 to 1.2 million electric cars.

Just last month, POSCO announced ‘Top 100 Reform Challenges’ to commemorate the 100th day of the CEO Jeong-Woo Choi’s inauguration. POSCO has been leading the second batteries market by developing customized products for its clients by integrating cathode and anode material businesses and by creating a research center for secondary battery materials. By 2030, the company is gearing up to grow it into a 1.5 billion USD (an equivalent of 17-trillion KRW) business, dominating 20% of global market share.

Furthermore, POSCO ChemTech plans to expand its business areas into high value-added carbon materials by establishing a needle coke production plant, which will become the raw material for anode materials and electrodes, by utilizing the byproducts generated during the steel making process.