The automobile is an important part of our daily lives. And steel is an important necessity to build cars that we drive. POSCO’s light, but also very durable automotive steel sheets are advancing the global auto industry. Is your car using steel sheets made by POSCO?

Steel products, an essential component for building cars!

The world’s first automobile, ‘Patent Motorwagen’ made its first appearance in 1886 and since then, over the past 130 years, cars have become status symbols and toys for the wealthy but also a convenient means for travelling from place to place. The essential component that builds cars is… steel!

Producing one car requires approximately 900 kilograms of steel! Are you surprised by the amount? They say that there are over 20,000 car components alone. Steel products are used throughout the automobile manufacturing process from the basic car body to engine motor, wheels to other major car components.

Wheels, doors, bumpers… steel plates that are suitable for each car component

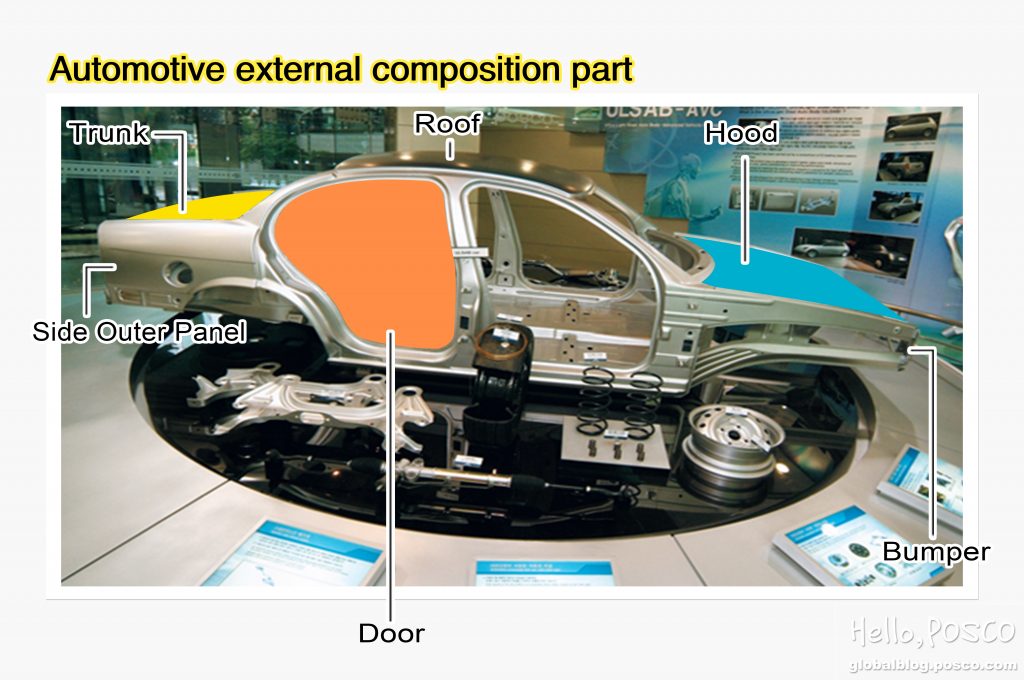

Automobile structures can be largely classified into two sections called BIW (Body in White) used for humans and freight and Chassis, space for the engine motor, tire wheels, breaks and other components necessary for driving.

Steel products used for cars are categorized based on their strength, durability and metallic characteristics. Car steel sheets that are suitable for each car component is applied.

For example, the hood or door of automobiles need to use steel that has some malleability in order for the parts to be shaped. At the same time, they must be durable to protect from exterior shocks such as car accidents and also have high quality exterior plating. To meet all these needs, 340MPa grade Bake Hardenable steels are used.

POSCO supplies to ‘Global Top 15’ Auto Companies

POSCO is a supplier to automobile companies not only based in Korea, but all over the world including companies such as Hyundai Motors, GM Korea, Renault Samsung Motors, TOYOTA, FIAT, Ford, Peugeot and more. In order to be a supplier of automobile steel sheets to such companies, there is a rigorous quality evaluation process that must be passed. POSCO has developed leading technologies and solutions to meet the needs of customers. Through close client communication and management, POSCO has been able to gain the trust of clients. Based on these marketing activities, POSCO aims to strengthen its position as a “Global Top Auto Materials Supplier”!

[box] Supplying products that meet the needs of clients globally

POSCO receives favorable reviews from Japan!

In the case of the Japanese auto market, companies preferred auto steel materials produced in their native country. In the 1990s, POSCO decided to proactively target sales marketing activities to the Japanese auto market. Eventually through close customer contact, care and by providing useful information about auto components’ quality, POSCO gained the trust of Japanese customers. As a result, POSCO supplies Japanese auto company plants not only in Japan, but also across their global network of plants in countries such as China, Thailand and India.

POSCO surpasses the Great Wall of China!

Auto manufacturing and sales numbers rose more than 20 million annually since 2013 making China the world’s largest car market. According to research by Global Insight, compared to the forecasted average global auto market growth rate of 3.6%, the forecast for China is a steady 6.5% growth rate from 2012. Based on these growth projections and to advance into the China market, POSCO built a processing center in China. Moreover, POSCO has addressed expanded demand for galvanized steel sheets by operating a Continuous Galvanizing Line (CGL) in Guangdong. In addition, to bolster Solution Marketing efforts, POSCO put in place a technical service center to target the optimistic outlook in the China market.

POSCO stands out even in the European market!

POSCO is providing competitive materials and technology to satisfy the standards of German auto manufacturers. Being able to meet the particular standards of leading German auto companies was a great achievement for POSCO as it recognized POSCO’s products as high quality. POSCO is also supplying to companies such as Renault, Fiat, BMW and plans to continue providing to the premium market.

Expanding the market from Mexico to the U.S.!

With its foothold in Mexico, POSCO is spreading sales of its automotive steel sheets out to the US market as well. Currently POSCO Mexico is supplying Mexican car manufacturers with materials, and 70% of the cars manufactured locally are being exported to the U.S. Furthermore, by providing differentiating materials, POSCO has greatly contributed to reducing production costs for auto manufacturers in Mexico.[/box]

POSCO’s Light yet Strong Automobile Steel Sheets

After POSCO CEO Kwon Ohjoon’s inauguration, he talked about automobile steel sheets as an example of the harmony of marketing and technology during a special lecture to employees.

“It’s true that high strengthening is necessary for weight reduction of cars, however excessively applying these measures might cause problems during the car manufacturing process. This is why Solution Marketing that provides the customer with a full problem-solving package consisting not only of steel materials but also formability and welding technology is so important,” said the CEO to emphasize the importance of unique Solution Marketing that differentiates POSCO from its competitors.

The idea goes hand in hand with the current trend of the automobile market: There is a growing drive to make cars lighter in order to boost fuel efficiency, while safety regulations are becoming stricter.

Pictured here: Robot at work at the Gwangyang Steel works

In order to fulfill the newly emerging needs of car manufacturers, POSCO is spurring its drive towards development and sales of AHSS (Advanced High Strength Steel) and other world-class premium products. AHSS is lighter yet stronger compared to other automobile steel products, making it an ideal material not only for the car exterior, but also for other auto components including side sills, which are attached to the lower body beneath the doors to absorb external impact.

As international regulations governing collisions and the environment are becoming more rigorous, the popularity of AHSS is spreading across the globe from the US to Asian car manufacturers. POSCO plans to further expand the market share of AHSS by providing customized technological solutions for various car manufacturers. POSCO’s endeavors in technology development and marketing are driven towards the goal of becoming the ‘World’s Number 1’ in automobile materials.

It is exciting and reassuring to know that many of the cars we see in our everyday lives are suited in a coat of POSCO steel armor!