The trends in POSCO Group’s flagship business area are explained by experts in an easy-to-understand manner. In the first part, we will look at the complexities of rechargeable battery materials with Sang-hyeon Seo, a senior researcher at the POSCO Management Research Institute (POSRI). With global attention turning to Africa to secure essential minerals for rechargeable battery production, POSCO Group has initiated strategic shifts in its supply chain dynamics. Let’s find out the status of Critical minerals in Africa and explore viable procurement strategies.

The spotlight is on lithium and cobalt as the core minerals for rechargeable battery materials. Lithium is a key element essential for manufacturing rechargeable batteries, and plays a role in determining the battery’s energy density. Cobalt, a critical ingredient in increasing battery capacity, is as an indispensable component for high-capacity rechargeable batteries, and its production area is concentrated in regions such as the Democratic Republic of Congo (D.R. Congo) in Africa. Notably, cobalt commands the highest price per ton among the core minerals for rechargeable battery materials.

As a consequence, there has been a surge in research to find substitutes for cobalt. One prominent example is the emergence of lithium iron phosphate (LFP) batteries, with leading contributions from Chinese enterprises. LFP batteries do not use cobalt, and have the advantage of cost-effectiveness, albeit with shorter driving ranges. Moreover, there is a notable drive for the development of batteries that incorporate manganese, which is only 1/30th the price of cobalt.

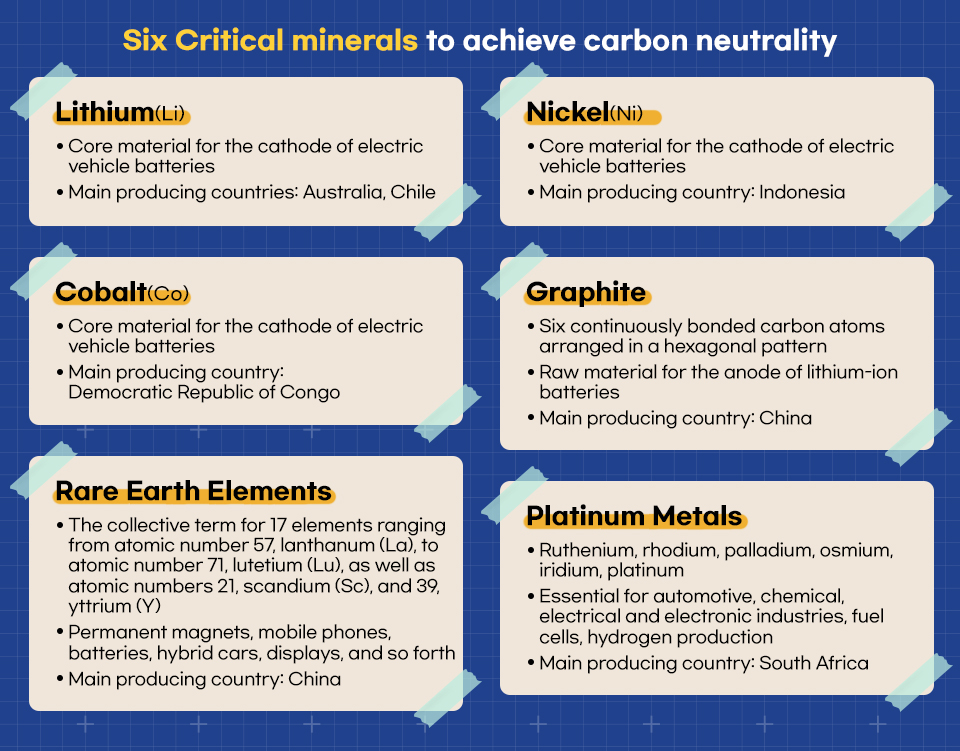

Moreover, securing essential minerals related to renewable energy, hydrogen technology, and other related fields is crucial to achieve carbon neutrality and energy transition. The Korea Institute of Geoscience and Mineral Resources has identified lithium, nickel, cobalt, graphite, rare earth elements, and platinum metals as the six critical minerals essential for realizing carbon neutrality and preparing for energy transition by 2022.

In particular, the platinum group metals are essential metals used not only in automotive, chemical, electrical, and electronic industries but also in fuel cells and electrolyzers for hydrogen production. As the global shift to a hydrogen economy gains momentum as a key pillar in achieving carbon neutrality, there is a foreseeable increase in demand for platinum group metals for future fuel cell applications.

Additionally, it is anticipated that the demand for rare earth elements, which are needed for permanent magnets in wind turbines, will more than triple by 2040. These rare earth permanent magnets are vital raw materials not only for renewable energy sources such as wind power but also for future eco-friendly mobility technologies such as smartphones, electric vehicles, hydrogen-powered vehicles, flying cars, and drone taxies.

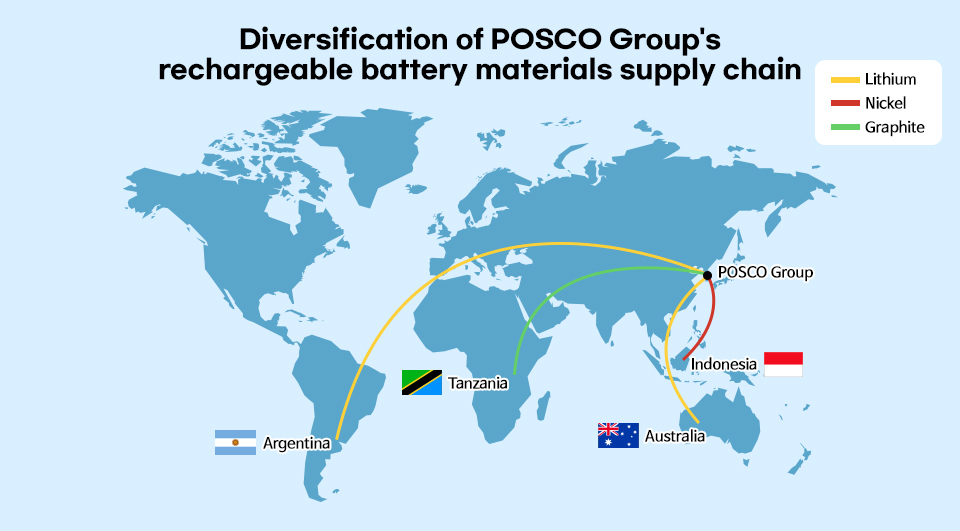

POSCO Group is currently the only company in South Korea that produces both cathode and anode materials at the same time. The cathode materials consist of nickel, cobalt, lithium, manganese, and the anode materials rely on graphite as a vital component. Currently, POSCO Group procures more than 80% of the core minerals for cathode materials and more than 90% for anode materials from China.

Amid escalating tensions between the United States and China, stricter sanctions on critical Chinese minerals by the U.S. and Europe are underscoring the urgent need to diversify supply chains. In response, POSCO Group is proactively diversifying its supply chain to countries such as Argentina, Australia, Indonesia, and Africa. Specifically, plans are underway to secure lithium from Argentina and Australia, nickel from Indonesia, and graphite from Africa.

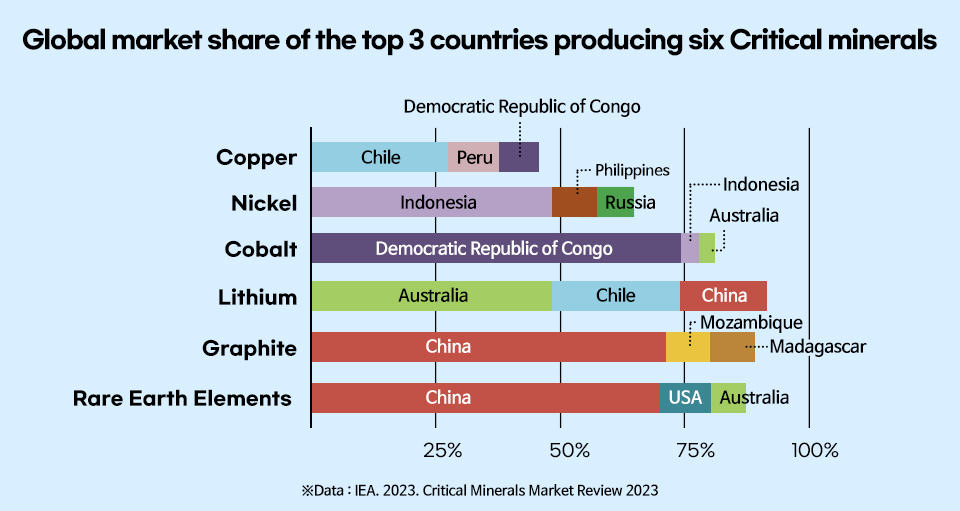

Africa is a rich mineral region that has approximately one-third of the world’s mineral reserves. In particular, cobalt, a key mineral, is produced in Africa, which accounts for more than 70% of global production, while for the platinum metals, it is more than 80%.

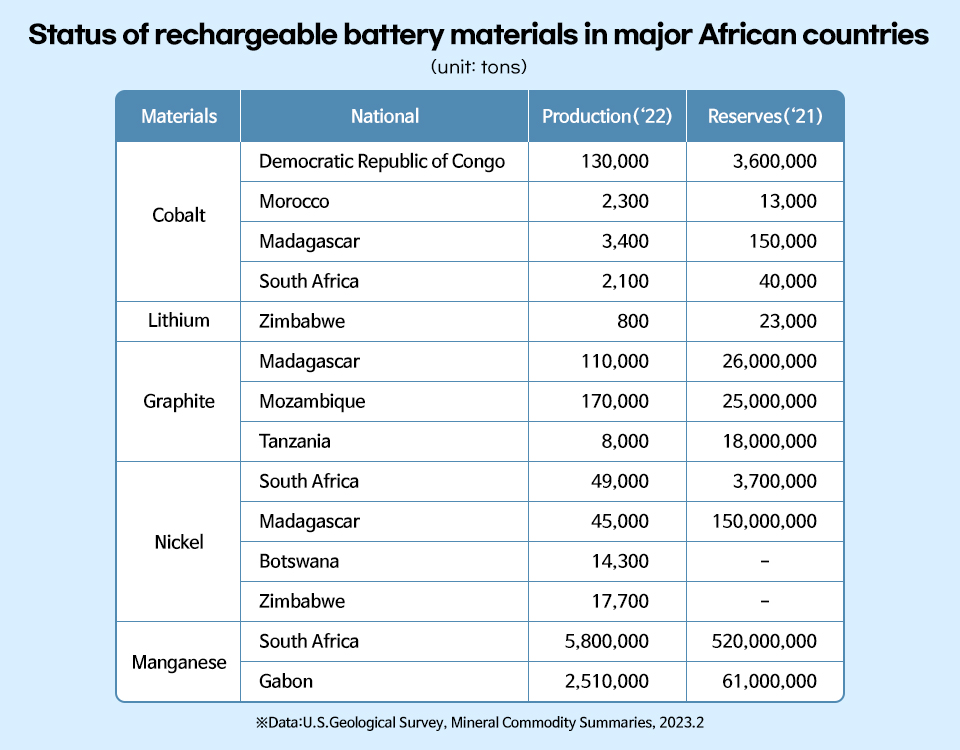

In recent years, there has been active lithium development in countries such as Zimbabwe, Namibia, and Morocco. This indicates a shift in lithium development from the traditional hubs in South America and Australia to Africa. Moreover, Mozambique produces more than 200,000 tons of natural graphite annually, and development projects are underway in Tanzania and Madagascar, which are rich in natural graphite reserves.

China has been proactive in securing Africa’s core minerals for a long time. As a result, Chinese companies have secured around 70% of African cobalt and have made significant investments in countries such as Zimbabwe and Namibia to secure lithium.

On the other hand, Europe and the United States are strengthening cooperation with mineral-rich African nations with the aim of preventing China from monopolizing Africa’s vital resources. In 2022, the United States initiated the Minerals Security Partnership (MSP) to promote cooperation with Europe, Japan, South Korea, and other nations.

Korean firms have yet to secure significant contracts for core mineral supplies in Africa. The most substantial investment is centered on the Ambatovy nickel mine and refining sector in Madagascar, where Korea Resources Corporation and POSCO International are actively involved. POSCO Group has also invested in acquiring stakes for natural graphite reserves in Tanzania and Madagascar. Meanwhile, LG Chem has initiated the establishment of a lithium production facility in Morocco in cooperation with China’s Huayou Group.

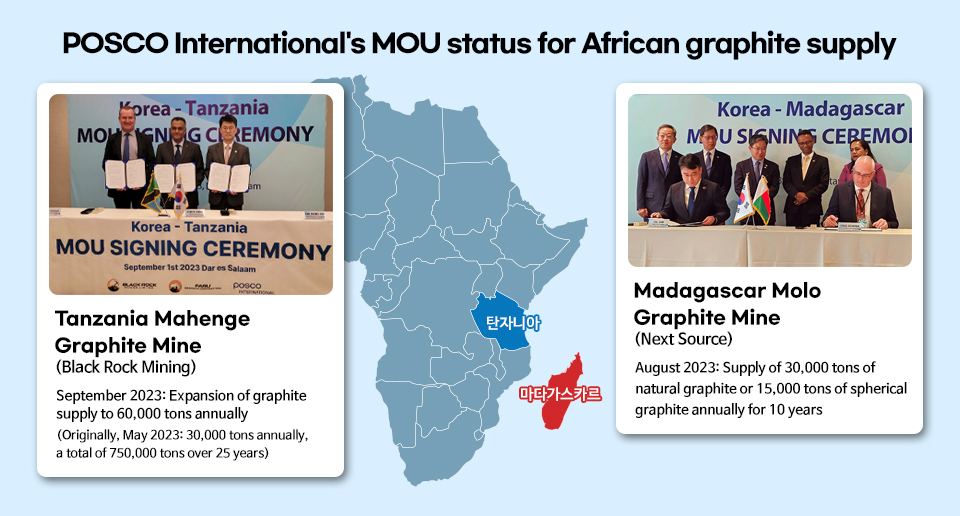

POSCO Group has initiated efforts to secure natural graphite by entering into an Agreement on the Establishment of a Graphite Supply Network with POSCO International in Madagascar and Tanzania. Additionally, POSCO Holdings acquired a 15% stake in Black Rock Mining, a company that owns graphite mines in Tanzania.

As mentioned earlier, POSCO Group heavily relies on imports of Critical minerals for rechargeable battery materials from China. While the group has been receiving a stable supply from China to produce cathode and anode materials, the escalating tensions between the U.S. and China and China’s control of exports of critical minerals pose risks to the supply chain. Therefore, POSCO Group intends to secure a stable supply chain for rechargeable battery materials by cooperating with global companies in mineral-rich countries. Securing natural graphite in Africa is part of this strategy.

POSCO Group has initiated efforts to secure natural graphite by entering into an Agreement on the Establishment of a Graphite Supply Network with POSCO International in Madagascar and Tanzania. Additionally, POSCO Holdings acquired a 15% stake in Black Rock Mining, a company that owns graphite mines in Tanzania.