POSCO Group produces the core steel materials required to drive the global shift toward decarbonization. Through high-performance steel products and tailored solutions, the Group enhances safety, efficiency, and durability across industries including oil and gas, power generation, and renewable energy, contributing to the sustainable growth of the global energy sector. Here, we take a closer look at POSCO Group’s key steel products that are shaping the future of energy infrastructure.

Powering the Energy Transition with POSCO Group’s High-Performance Steel

The global energy landscape is undergoing a profound transformation. While technologies such as renewable energy, hydrogen, LNG, and CCUS continue to advance in pursuit of carbon reduction, it is advanced materials that ultimately enable these innovations to become reality. POSCO Group is supporting the advancement of next-generation energy infrastructure by providing steel engineered to perform under extreme environments and demanding conditions. From PosMAC, a high-corrosion-resistant alloy-coated steel used in renewable energy infrastructure, to steel forming the foundation of hydrogen pipeline systems, high-manganese steel recognized as a key material for liquefied hydrogen storage tanks, and LT-FH36, a core steel for LCO₂ carriers, POSCO’s high-performance steel products are applied across a wide range of energy transition industries, each tailored to specific application requirements.

Strengthening ESS Safety with PosMAC: A High-Corrosion-Resistant Alloy-Coated Steel

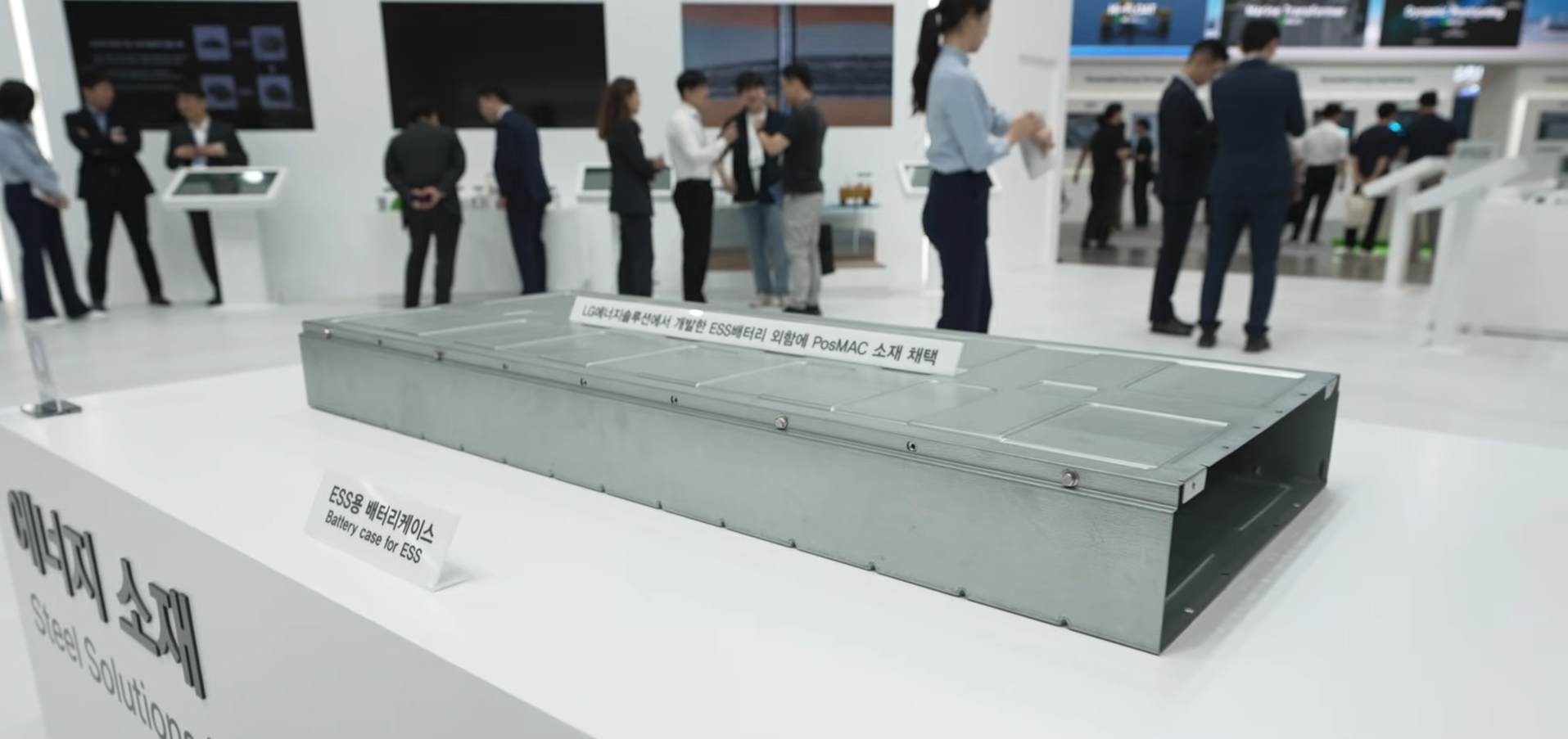

▲ PosMAC is used as a material for ESS battery cases developed by LG Energy Solution.

As renewable energy expands and power efficiency becomes increasingly important, demand for energy storage systems (ESS) continues to rise. Because ESS must store electricity safely and reliably over long periods, corrosion-resistant materials are essential. POSCO’s high-corrosion-resistant alloy-coated steel, PosMAC, is widely used in ESS battery enclosures, ensuring long-term stability and durability.

PosMAC offers more than five times the corrosion resistance of conventional galvanized steel, maintaining reliable performance even in coastal, high-humidity, and high-salinity environments. This durability helps reduce carbon emissions and overall lifecycle costs. As a result, PosMAC is extensively applied across renewable energy infrastructure, including wind turbine tower components, offshore wind structures, and solar module mounting systems. By extending equipment lifespans and reducing maintenance requirements, PosMAC plays a key role in driving the growth of sustainable energy.

Beyond ESS battery enclosures, PosMAC is expanding into a wider range of components, including racks and Battery Protection Unit (BPU) cases. Through close collaboration with customers, POSCO continues to enhance the product’s reliability and application range, reinforcing PosMAC’s position as a core material in the renewable energy industry.

Steel for Hydrogen Pipelines: The Foundation of Hydrogen Infrastructure

▲ Model of hydrogen pipeline steel exhibited at the POSCO Group booth at the 2025 International Climate Industry Expo.

Hydrogen is a cornerstone of future clean energy systems, requiring uncompromising safety throughout its entire value chain—from production and storage to transportation. In particular, pipelines transporting high-pressure gaseous hydrogen must resist hydrogen embrittlement* while maintaining reliable performance under extreme conditions.

*Hydrogen embrittlement: A phenomenon in which hydrogen penetrates a material, significantly reducing the ductility and toughness of the metal.

POSCO’s steel for hydrogen pipelines was designed to meet these stringent requirements. By replacing imported seamless pipes previously used for hydrogen transport, POSCO has enabled domestic production while offering strong cost competitiveness, supplying the product at approximately 70% of the cost of imported alternatives. The steel provides sufficient strength and toughness to withstand impact at temperatures as low as –45°C, not only in the pipe body (base material) but also at welded joints. After rigorous testing by international certification bodies, it has been confirmed to meet hydrogen pipeline performance standards, earning official recognition for its safety and reliability.

By 2025, POSCO plans to introduce high-strength materials compliant with API X70 standards for use in high-pressure environments of up to 100 bar. Demonstration and verification testing will be conducted in collaboration with Korea Gas Corporation (KOGAS), Korea Gas Safety Corporation (KGS), Korea Research Institute of Standards and Science (KRISS), and domestic steel pipe manufacturers.

*API (American Petroleum Institute): An organization that establishes international standards for pipelines and steel products used in the oil and gas industry.

Challenging –253°C: High-Manganese Steel for Liquefied Hydrogen Storage Tanks

▲ Model of high-manganese steel liquefied hydrogen storage tank exhibited at the POSCO Group booth at the 2025 International Climate Industry Expo.

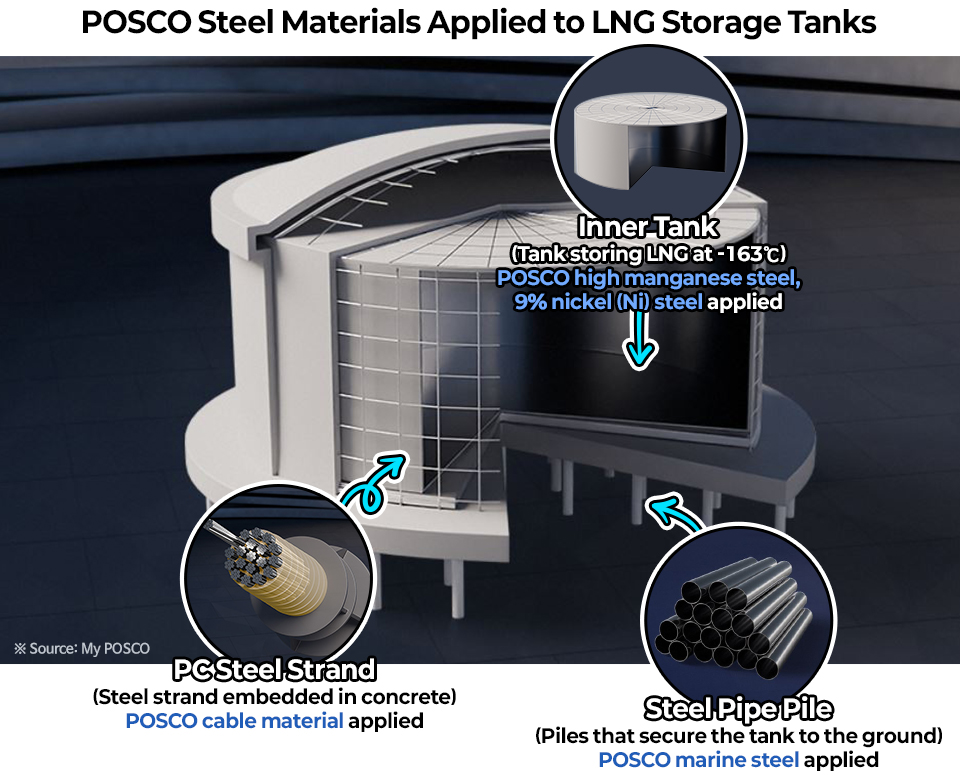

Liquefied hydrogen (LH₂) is drawing global attention as a core technology for hydrogen transportation and storage in the hydrogen economy. Stored and transported at an ultra-cryogenic temperature of –253°C, liquefied hydrogen places significantly higher demands on storage tank materials than liquefied natural gas (LNG), which is handled at approximately –163°C. Against this backdrop, POSCO’s high-manganese steel is recognized as a key material capable of maintaining stability under such extreme conditions.

Independently developed by POSCO as the first of its kind in the world, high-manganese steel contains more than 22% manganese (Mn). It offers outstanding performance at cryogenic temperatures while offering a unique combination of high strength, excellent wear resistance, and non-magnetic properties that minimize electromagnetic effects. Its yield strength exceeds 335 MPa—approximately twice that of conventional stainless steel—while high elongation ensures excellent formability. In addition, relatively low manufacturing costs* contribute to its economic competitiveness. As a result, high-manganese steel is widely used in LNG infrastructure, including storage tanks, carriers, pipelines, and terminals.

*Manganese used in high-manganese steel is abundant worldwide and relatively inexpensive.

▲ Inside view of Tank No. 7 at Gwangyang LNG Terminal 2. High-manganese steel has been applied to the inner tanks of Units 5 and 6, and it is planned to be applied to Units 7 and 8 to be constructed in the future.

Over the past decade, POSCO’s high-manganese steel has proven its reliability through certifications from leading global classification and certification bodies. In 2022, the International Maritime Organization (IMO) formally adopted international technical standards governing its application, allowing the material to be used in cryogenic cargo and fuel tanks without separate flag-state approval. In 2024, it was further registered under standards applicable to both LNG and ammonia cargo and fuel tanks.

Building on its extensive experience in LNG infrastructure, POSCO is working to improve the performance of high-manganese steel so that it can reliably withstand impact even at –253°C. Going forward, the company plans to conduct demonstration projects and feasibility assessments through the fabrication of liquefied hydrogen storage tanks in collaboration with customers, aiming to secure both safety and economic viability for future hydrogen infrastructure.

Applied to the World’s Largest 22,000㎥ Vessels: Steel for LCO₂ Carriers

▲ AI virtual image of a liquefied carbon dioxide (LCO2) carrier.

Liquefied carbon dioxide (LCO₂) carriers are specialized vessels designed to safely store and transport carbon dioxide captured through CCUS processes after it has been cooled and compressed into liquid form. As the carbon capture and storage (CCS) industry continues to expand, the need for materials that support safer and more efficient vessel operations is becoming increasingly critical.

Unlike LNG and ammonia, which can be transported in liquid form under low-temperature conditions alone, carbon dioxide must be transported under both low temperature and controlled pressure. Scaling up liquefied carbon dioxide storage tanks therefore requires advanced steelmaking technologies.

POSCO’s LT-FH36 steel for LCO₂ carriers is engineered to maintain stable performance at temperatures as low as –60°C, reflecting the design conditions of low-pressure LCO₂ tanks. It can be applied in thicknesses of up to 50 mm and provides a yield strength exceeding 355 MPa. Even after post-weld heat treatment (PWHT), the steel maintains stable mechanical properties, ensuring long-term reliability in environments with elevated risks of corrosion and structural failure.

LT-FH36 is the world’s first steel to receive certification for use in large-scale liquefied carbon dioxide transport tanks. In 2023, at the international maritime exhibition Nor-Shipping, Lloyd’s Register (LR), a globally recognized British classification society, awarded POSCO official certification for steel used in large-scale LCO₂ carriers.

▲ The world’s largest 22,000㎥ liquefied carbon dioxide (LCO₂) carrier currently under construction at HD Hyundai Mipo. It uses POSCO’s LT-FH36 steel.(Photo source: HD Hyundai Heavy Industries)

LT-FH36 is currently applied to the world’s largest 22,000m³-class liquefied carbon dioxide carriers. In anticipation of the industry’s shift toward ultra-large storage tanks to improve transport efficiency, POSCO has also become the first in the world to complete the development and certification of LT-FH51, a higher-yield-strength steel grade. Over the longer term, the company plans to introduce even stronger grades, such as LT-FH70, further strengthening the safety and efficiency of next-generation LCO₂ carriers.

From PosMAC and steel for hydrogen pipelines to high-manganese steel and LT-FH36, POSCO Group’s independently developed high-performance steel products are delivering greater safety, efficiency, and sustainability across the energy industry. POSCO Group will continue to strengthen its materials technologies to help shape the infrastructure of the future global energy landscape.