Jeong-hu Hong, Lead Researcher Today, secondary battery materials are drawing attention as key drivers of future industries such as electric vehicles and energy storage systems. Among them, cathode materials are especially important, accounting for more than 35% of the total cost of the four major battery components—cathode, anode, electrolyte, and separator. This is because cathode materials determine not only a battery’s capacity and output but also its ability to store and release electrical energy.

At the Cathode Material Development Group, POSCO Future M Technology Research Institute, we conduct research on cathode materials, the core of EV batteries, and develop new technologies to bring them into commercial use.

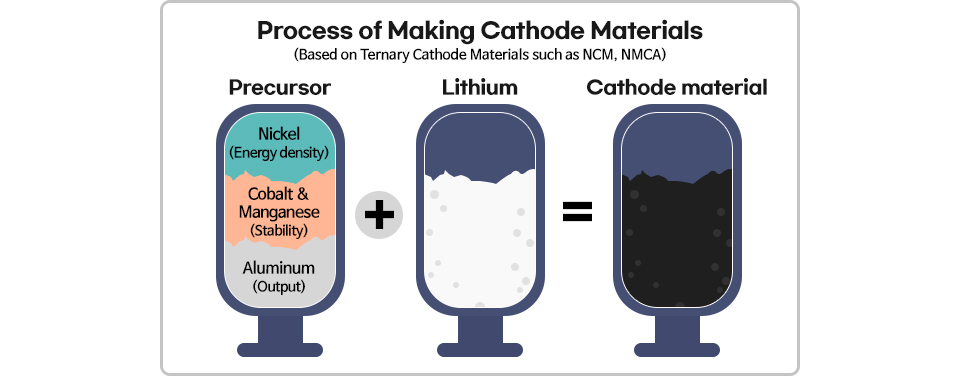

Do-hyeop Park, Principal Researcher Cathode materials can be simply defined as a “source of lithium.” They are produced by combining lithium with precursors made of various metals such as cobalt, manganese, and nickel. The battery’s name, performance, and stability all depend on which metals are used. Batteries such as Lithium Cobalt Oxide (LCO), Nickel Cobalt Manganese (NCM), Lithium Iron Phosphate (LFP), and Lithium Manganese Rich (LMR), among many others using different metal combinations, are currently being developed. Our team, in particular, focuses on the development of LMR cathode materials. Recently, General Motors (GM) and Ford announced plans to launch electric vehicles using LMR batteries in 2028 and 2030, respectively, drawing significant attention to LMR in the global automotive market. Our team is fully committed to advancing LMR batteries, which are poised to become game-changers in the electric vehicle industry.

Gwang-eun Jeong, Principal Researcher Among the lithium-ion batteries currently used in electric vehicles, LFP batteries are the most widely adopted. These batteries are predominantly developed technologically by China. While these are highly stable and cost-effective, their energy density is somewhat limited. For instance, at -10°C, their performance drops to only 60–70% of full capacity. To overcome these limitations, a newly developed LMR battery has been introduced. LMR batteries significantly reduce the use of costly cobalt and nickel, while increasing the proportion of more affordable manganese. With higher energy density than LFP, they enable greater battery capacity and performance, significantly extending the driving range of electric vehicles. Moreover, unlike LFP batteries, which are difficult to recycle, LMR batteries offer superior recyclability and high lithium recovery rates.

Jeong-hu Hong, Lead Researcher The LMR battery demonstrates outstanding competitiveness not only in terms of cost and performance but also in sustainability. Of course, despite its many advantages, there are challenges that must be addressed before mass production can be realized. To prevent performance degradation, various technological advancements are required, including maintaining stable average voltages and developing surface coating techniques for cathode materials to suppress unnecessary gas generation. In China, a large-scale LFP mass production system is already in place, making a swift transition to LMR production challenging. As a result, innovative research and development are even more crucial. Our team, after an intricate R&D process, has successfully completed the development of LMR cathode materials and is now focusing on establishing techniques for mass production.

Do-hyeop Park, Principal Researcher We divided the R&D process into laboratory and pilot production stages. In the laboratory stage, we rapidly and accurately explored the basic characteristics and optimal combinations of cathode materials under specific process conditions. Through creativity and experimentation, we successfully identified the best material combinations, reducing costs while enhancing the performance of LMR cathode materials.

Ju-hyeon Yang, Principal Researcher As Do-hyeop Park mentioned, cathode production involves a calcination process, where various metal precursors such as nickel, cobalt, manganese, and aluminum are combined with lithium sources at high temperatures. During this process, we selected a variety of precursor candidates, evaluated their key physical properties, and identified the most promising materials for experimental application. By applying accumulated technical knowledge and analyzing the effects of variables throughout the development process, we successfully optimized LMR cathode materials, evaluating their initial battery capacities and lifespans. Through continuous refinement of material design, process conditions, and experimental testing, we were also able to assess the feasibility of mass production.

Jin-eun Kim, Principal Researcher This is not the end. Even if promising results are achieved in the laboratory, the performance of the developed cathode material may not be fully realized under conditions similar to those of mass production. Therefore, during the pilot stage, we adjusted loading amounts, production volumes, and sintering furnace conditions on lines that closely resemble actual mass production, repeatedly experimenting to identify the optimal production conditions.

Ji-su Kim, Principal Researcher In the laboratory stage, cathode materials can be sintered in quantities of 100 to 200 grams; however, customers occasionally request samples ranging from kilograms to tons. This means that during the pilot stage, cathode materials must be produced stably at the same performance level as those from the laboratory to allow customers to properly verify mass production feasibility. From our perspective, securing the optimal conditions for cathode material production made this stage particularly important.

Jeong-hu Hong, Lead Researcher Together with our team members, we conducted full-scale R&D to enhance the safety of the LMR process. Pilot lines require meticulous adjustment of conditions, as even slight process changes can significantly impact cathode performance. By repeatedly verifying various conditions and applying laboratory-designed firing processes to actual equipment, we achieved stable pilot production of cathodes with performance comparable to that secured in the laboratory, passing customer evaluations and finalizing the technology. Thanks to this work, we were able to secure optimal pre-mass production conditions and improve economic efficiency.

Gwang-eun Jeong, Principal Researcher I remember being quite flustered when we received a request from a customer to deliver pilot samples within just ten days. We had to simultaneously respond to the customer and optimize the material. In that situation, I decided to stay calm and divide roles among the team: I communicated with the customer to gather requirements, while Do-hyeop Park focused on optimizing experimental conditions. Thanks to everyone diligently working in their respective roles, we successfully met the customer’s requested delivery date and ensured proper material quality.

Do-hyeop Park, Principal Researcher At that time, with very little time remaining until the pilot sample delivery, it was challenging not only to produce samples but also to refine the material simultaneously. That’s when Gwang-eun Jeong, our team’s “maestro,” who perfectly coordinates our efforts, efficiently allocated roles. Thanks to this, we managed to produce the samples on time without any issues. It would have been impossible to accomplish this alone.

Jin-eun Kim, Principal Researcher There were moments during the pilot phase when performance fell short of expectations. Although the goals had been achieved in the lab, results in the pilot phase differed significantly, which was perplexing. We then collaborated to meticulously review each process step by step to identify the cause. By theoretically analyzing with Jeong-hu Hong and conducting repeated experiments with adjusted mixing times and sequences, we observed remarkable improvements in performance!

Jeong-hu Hong, Lead Researcher Currently, the global battery market’s core materials and component supply chains remain heavily concentrated in China, making the establishment of independent supply chains a critical task. Our foremost goal is to successfully commercialize LMR batteries with a stable supply chain and robust technical expertise. Moving forward, we plan to actively pursue research and development to create better batteries across multiple aspects, including enhancing material stability, securing cost competitiveness, and improving charge/discharge performance. To achieve this, I will collaborate closely with relevant departments such as production, quality, and sales. Ultimately, our team aims to join forces to successfully mass-produce LMR, a next-generation battery material, and become a future growth engine for the POSCO Group!