As competition to develop all-solid-state battery technology has become more intense worldwide, POSCO Group is also actively researching and developing raw and key materials for all-solid-state batteries. POSCO N.EX.T Hub is where R&D is carried out. So! Announcer Hyun-jung Choi went to POSCO N.EX.T Hub Senior researcher Oh-min Kwon, an expert in all-solid-state batteries, and talked about all-solid-state batteries, which become more fascinating as you learn more about them. Anyone curious about the all-solid-state battery core material business that the POSCO Group is preparing should pay close attention. It starts right now!

What is the difference between all-solid-state batteries and lithium-ion batteries?

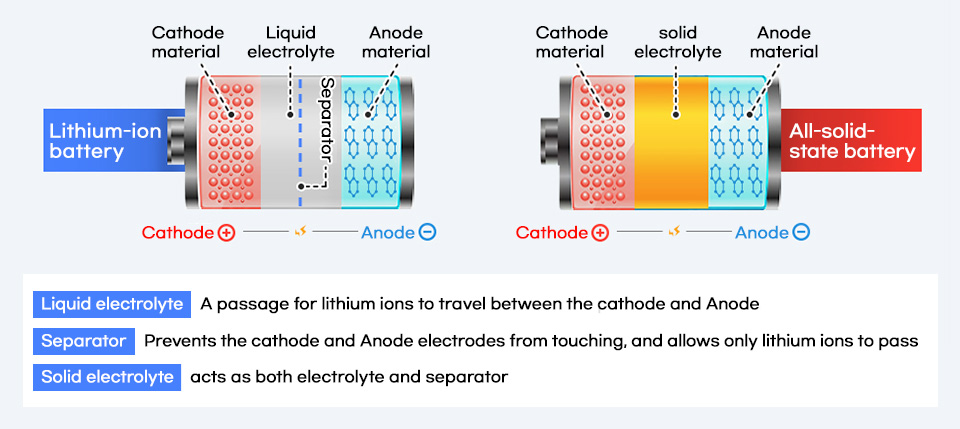

Do you know what type of rechargeable battery is most commonly used in electric vehicles today? It is a lithium-ion battery. Among the components of lithium-ion batteries, the electrolyte, which helps lithium ions move smoothly between the cathode and anode, is made of liquid. Since the liquid electrolyte contains a flammable organic solvent, there is a high risk of fire or explosion in high-temperature environments or external impact situations.

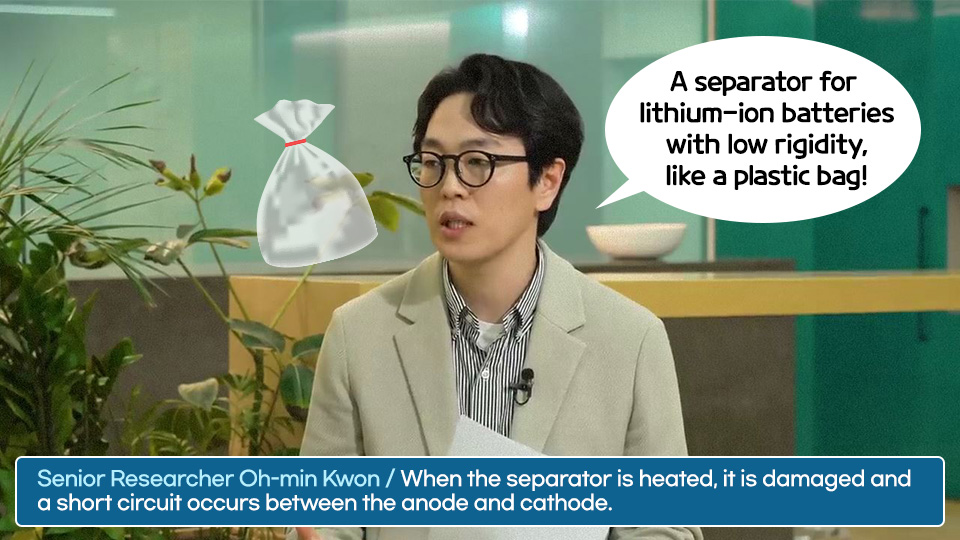

The separator acts as a shield that prevents direct contact between the cathode and anode, and the lithium-ion battery separators are made of polymer, which is the main material of vinyl bags that we see everywhere in our daily lives. Just as vinyl bags shrink and disappear when heated, the lithium-ion battery separator can also be damaged when heated, and it causes a short circuit* between the cathode and anode.

*Short circuit: A phenomenon in which two points in an electric circuit are connected due to poor insulation between the two points

All-solid-state batteries replace the liquid electrolytes used in conventional lithium-ion batteries with a solid electrolyte. Unlike the polymer separator of a lithium-ion battery, which is made of polymer with low rigidity, the solid separator is made of ceramics with high rigidity. Moreover, it is non-volatile and has a high flash point, so it maintains its shape well even when heated, which keeps it safe from fire.

Improved safety simplifies the heat management system, such as the external case or cooling device in the battery, so it features higher energy density in the battery pack unit. Improved energy density can significantly increase the range of electric vehicles driving on a single charge. In addition, it makes it possible to use materials such as lithium metal anodes, silicon anodes, and silver/carbon nanocomposite anodes, which were previously unusable due to high risk in lithium-ion batteries. The energy density is expected to increase by nearly 10 times compared to existing graphite anode materials. That explains why all-solid-state batteries have become the next-generation batteries for the transition from internal combustion engine vehicles to electric vehicles.

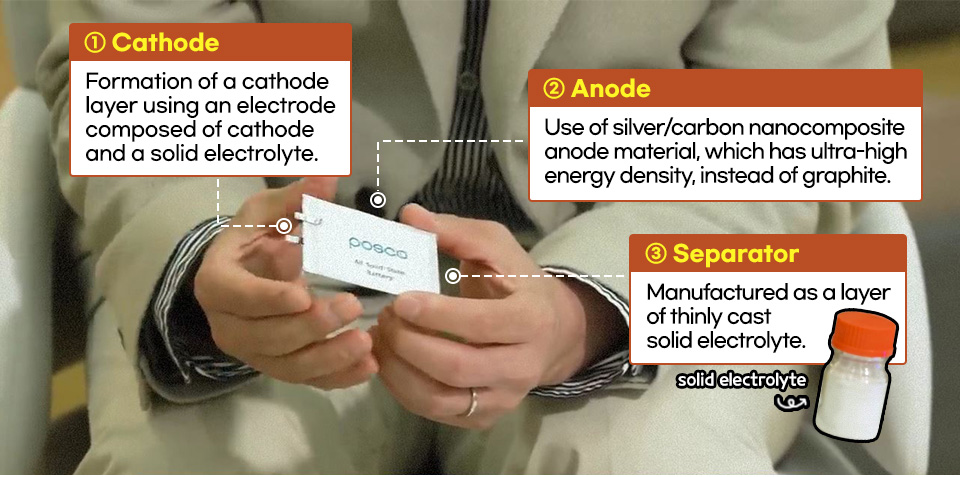

For those who cannot understand by explanation alone, Senior researcher Kwon brought all-solid-state battery samples produced by the POSCO Group and conducted a performance test. First, before we see the results! Let’s look at the specifications of POSCO Group’s all-solid-state batteries more closely.

Specifications of POSCO Group’s all-solid-state batteries

He connected the cathode and anode to a battery that looked like a thin piece of paper at first glance, made it light up, and then cut the surface of the battery with scissors. Will the light still be on even if it is cut?

Like magic, the light does not go out even when the battery is cut in half. The secret behind this is that the solid electrolyte of the all-solid-state battery, with high rigidity, acts as a separator and remains intact even with external shocks. If the inside of the battery was filled with a liquid electrolyte, the separator would have been damaged and caused the electrolyte to leak and be oxidized, and the battery would eventually stop functioning properly. That is why everyone recognizes all-solid-state batteries to be the next-generation battery leader.

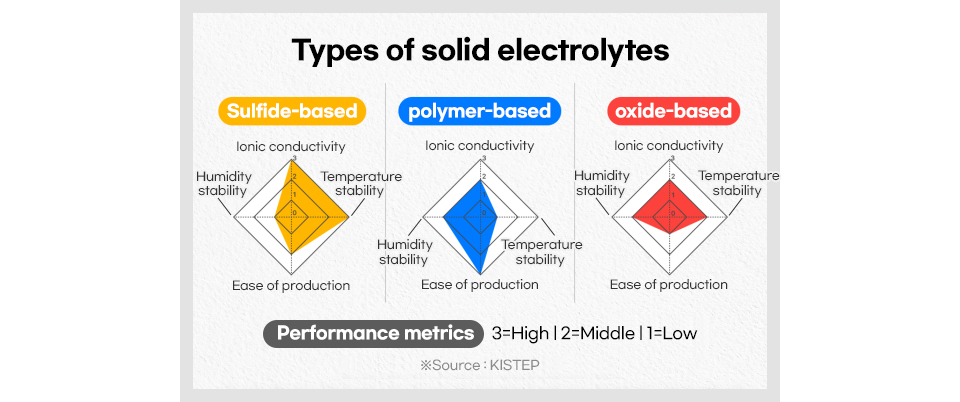

So, what are the types of solid electrolytes for all-solid-state batteries? The solid electrolytes used in all-solid-state batteries are divided into three types: sulfide, polymer, and oxide. Sulfide solid electrolytes have the highest potential for commercialization in electric vehicles since their relatively soft characteristics form a wide interface between the electrode and electrolyte, resulting in high lithium-ion conductivity. Therefore, it has gained the attention of many companies worldwide.

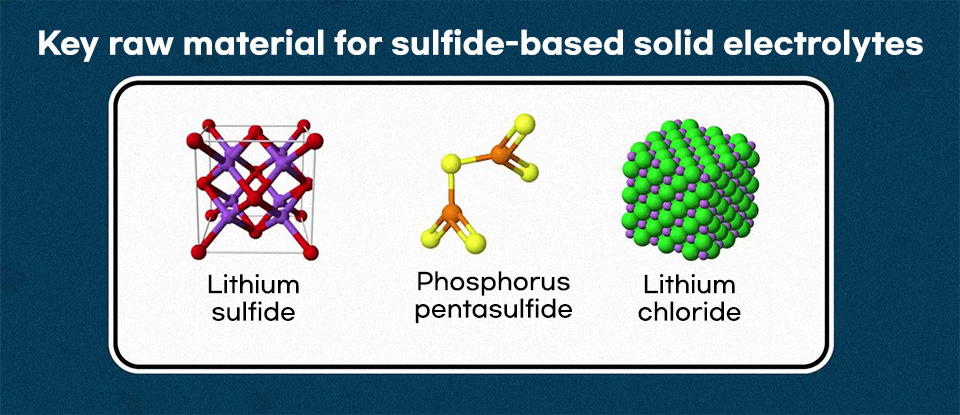

Three key raw materials are needed to make a solid electrolyte: lithium sulfide, phosphorus pentasulfide, and lithium chloride. These three raw materials are mixed evenly to form an argyrodite (a rare mineral of silver, germanium, and sulfur) by synthesis. What is important is for the synthesis to form the appropriate solid electrolyte particle size. The solid electrolyte is completed by controlling the particle size through the crushing* and disintegration** processes.

*Crushing: The process of breaking a solid object into small pieces

**Disintegration: The process of separating clumped particles into the original individual particles

Status of POSCO Group’s all-solid-state battery material business

Did you know that POSCO Group is focusing its business on sulfide solid electrolytes to take a leading position in the all-solid-state battery market? POSCO Holdings is developing high-ion conductive materials and technology to form moisture-stable solid electrolytes. The internal testing of the prototype showed that it can achieve a battery performance equivalent to that of lithium-ion batteries.

In February 2022, it acquired a 40% equity share of Jeongkwan Co., Ltd., a display material and part specialist, to establish a joint venture called POSCO JK Solid Solutions, and completed the construction of a factor capable to producing 24 tons of sulfide-based solid electrolyte per year. The plant recently applied a new process technology and is preparing a phased expansion of the production capacity to 7,200 tons. It is currently conducting an all-solid-state battery test with various customers.

▲POSCO Group’s lithium production demonstration plant and brine storage facility in Argentina.

POSCO Group is the only Korean company that produces lithium brine, ore, hydroxide, and carbonate. Moreover, POSCO Group is actively researching and developing high-value-added lithium compounds. Since lithium compounds such as lithium sulfide and lithium chloride are essential to produce solid electrolytes, POSCO Group, which has lithium production infrastructure, is considered to have considerable competitiveness in the sulfide-based electrolyte business.

All-solid-state batteries will overcome the limitations of lithium-ion batteries, and solid electrolyte is their key material. In addition to solid electrolytes, POSCO Group also has the competitiveness to mass-produce lithium metal anode materials, which are important materials for all-solid-state batteries. With our differentiated competitiveness, we plan to leap forward as an innovative company in the rapidly changing rechargeable battery material market. If you want to know more, please watch the full version of the video on YouTube.