Save your valuable time. Watch a short version of a long YouTube video in just 3 minutes! In this episode, join us in discovering POSCO Group’s future roadmap as it emerges as a global top-tier player with the domestic production of cathode and anode materials, the key elements of rechargeable batteries.

POSCO has recently received widespread attention for its impressive growth and innovation in identifying future demand industries. In particular, POSCO Group has emerged as a formidable force both at home and abroad in cutting-edge technologies such as mobile devices, electric vehicles, solar panels, and renewable energy storage systems. In Korea, only POSCO Future M is producing both cathode and anode materials, which are important materials that determine rechargeable battery performance, and has established itself as one of the major suppliers of high-quality rechargeable battery materials and is producing both anode and cathode materials.

Today, let’s look at the future of batteries with Senior Researcher Park Jae-beom at the POSCO Research Institute, which is focusing on anode materials that influence battery lifespan and charging speed. Join us as we explore POSCO Group’s blueprint that will shape the future of batteries. Let’s begin now!

Graphite: the core mineral that shapes the performance of electric vehicle batteries

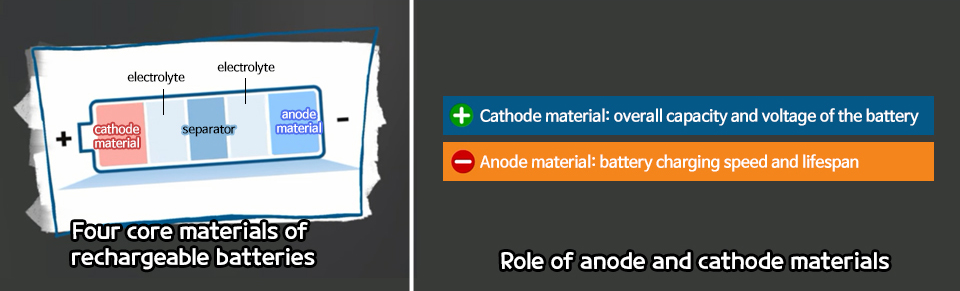

As nations worldwide intensify efforts to reduce carbon emissions, the traditional automotive industry is undergoing a profound metamorphosis. It is shifting away from its reliance on internal combustion engines, pivoting to the era of electric vehicles, and embracing eco-friendly energy sources. Rechargeable batteries are at the center of electric vehicle production. A rechargeable battery consists of four materials: a cathode, an anode, an electrolyte, and a separator. It is no exaggeration to say that the cathode material, which determines the driving distance of an electric vehicle by increasing the energy density, and the anode material, which affects the charging speed and life of the battery, determine the performance of rechargeable batteries.

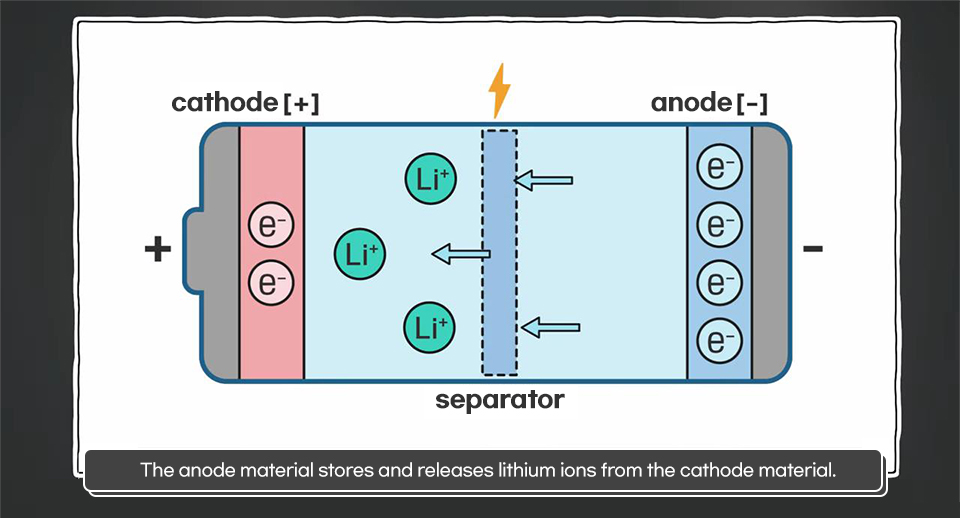

Lithium-ion batteries, commonly found in electric vehicles, produce electricity with the chemical exchange of lithium ions between the cathode and anode. The anode stores and releases lithium ions received from the anode material. In other words, battery performance hinges on the anode’s performance, and its ability to efficiently store and release lithium ions directly affects energy density and charging speed. Recent emphasis has been placed on developing anodes with heightened energy density, swift charging capabilities, and robust durability, to match the importance given to cathodes.

The primary material of the anode is graphite, much like the substance found in everyday items such as pencil leads or mechanical pencil refills. Metal is also used as a production material for anode materials, but graphite-based anodes dominate the market due to their affordability and high stability, and account for approximately 90% of anode production. Therefore, the majority of anode materials currently used in the market are made of either natural or synthetic graphite.

Sole provider in Korea! POSCO Group produces both natural and synthetic graphite

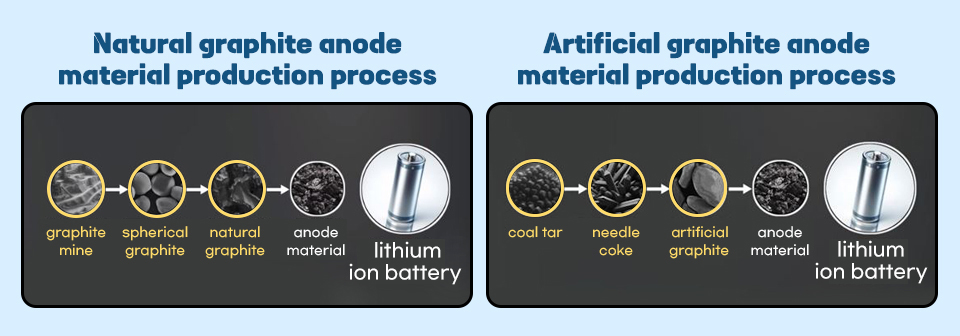

Natural graphite is obtained from mines as graphite ore, crushed to remove impurities, and refined to increase its purity in a process known as beneficiation. The resulting raw graphite undergoes various processes to be shaped into spherical graphite. Spherical graphite is coated with pitch and subjected to high temperatures in a process called calcination. This coating serves to encapsulate the graphite surface and enables the battery to withstand high temperatures and improve charging and discharging efficiency. Finally, the graphite undergoes size grading and iron removal, culminating in the production of natural graphite anode material with a purity approaching 99.9%.

Artificial graphite, used as an anode material, is produced from coke, a byproduct of steel production, rather than directly mined from graphite. Coke undergoes purification to remove impurities, followed by high-temperature treatment, resulting in needle coke formation. The needle coke is then pulverized, subjected to high temperatures for graphitization, and undergoes coating and iron removal processes to produce artificial graphite anode material.

The naturally derived graphite anode material and the synthetic graphite anode material, produced by different manufacturing processes, complement each other. The natural graphite anode material offers the advantage of large lithium-ion storage capacity at a low cost, while the synthetic graphite anode material is advantageous in terms of lifespan, output, and stability. For these reasons, a majority of rechargeable batteries for electric vehicles use a combination of natural and synthetic graphite.

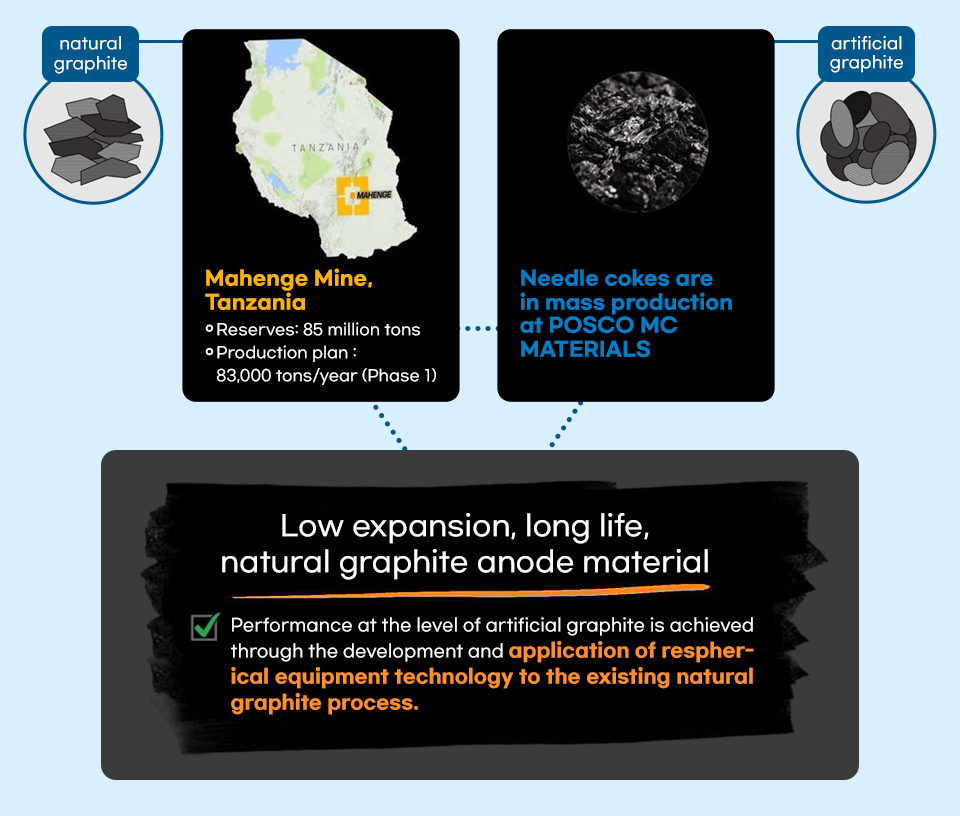

POSCO Future M is the only Korean company that produces both natural and synthetic graphite anode materials. Natural graphite is planned to be secured from the Mahenge and Molo mines in Tanzania and Madagascar, which are invested by POSCO Holdings and POSCO International, in addition to existing suppliers. Synthetic graphite, on the other hand, has been successfully localized with the procurement of raw materials, needle cokes, by its subsidiary, POSCO MC Materials. Furthermore, through R&D collaboration with POSCO Holdings, POSCO Future M has developed a low-expansion, long-life natural graphite anode material that combines the advantages of synthetic and natural graphite.

Recently, China, responsible for approximately 70% of global graphite production, announced plans to tighten control over its graphite exports. Amidst the electric vehicle market’s expansion, China’s recent announcement of full control over graphite exports has dealt a significant blow to battery manufacturers worldwide. This declaration comes at a time when the anode material sector is experiencing annual growth rates of more than 20%. While this poses challenges for battery manufacturers worldwide, POSCO Group’s competitive position in the battery market is increasingly noteworthy. POSCO has been strategically advancing its anode material business to bolster self-reliance and reduce reliance on China since 2010. In the future, POSCO Group is expected to enhance its supply chain capabilities in the anode material sector and increase production autonomy.

POSCO Group leads battery industry with “full portfolio” development

Establishing a production system for silicon anode materials with a capacity of 35,000 tons by 2030

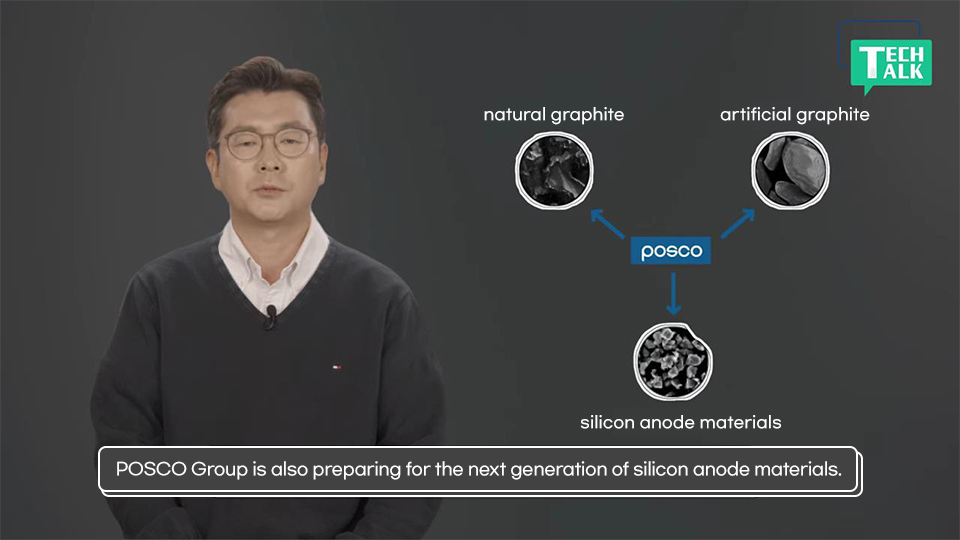

POSCO Group’s strategy to strengthen battery performance with anode material technology is expected to continue to develop. With the global demand for high-performance electric vehicles, batteries also need high-performance materials, leading to increased attention to various anode materials. Among them, you can mention silicon anode materials.

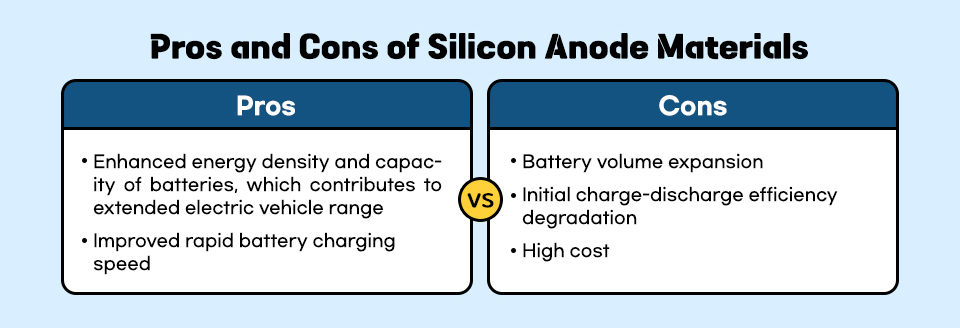

Silicon anode material has a nearly tenfold higher capacity per unit weight compared to graphite-based alternatives, which has the advantage of innovatively increasing electric vehicle range and facilitating rapid charging. However, it comes with challenges. The higher cost and structural instability of silicon due to volume expansion during charge and discharge are significant obstacles to overcome.

Due to these technical challenges, silicon anode material is currently not used exclusively in electric vehicle batteries. Instead, it is blended with graphite-based anode materials at a ratio of 4-5%. Nevertheless, silicon anode material is gaining attention as a potential solution to improve electric vehicle driving range and charging performance. Some in the industry foresee increasing the proportion of silicon in anode materials from 5% to 30% by 2030 with the development of technologies that enhance material structure stability. The silicon anode material market is expected to grow at an annual rate of 34%.

Consequently, POSCO Group is strategically consolidating its research efforts internally to drive the development of a production ecosystem for silicon anode materials, the cornerstone of next-generation products. Within this framework, POSCO Holdings has established its subsidiary, POSCO Silicon Solution. Furthermore, with the combined expertise of POSCO N.EX.T Hub (Future Technology Research Institue) and POSCO Future M, the Group plans to work together to build a production infrastructure capable of yielding 35,000 tons of silicon anode materials by 2030.

Harnessing its infrastructure, it will mass-produce next-generation lithium metal anode materials

In addition to silicon anode material, which boasts more than 10 times the energy density of graphite, another promising next-generation anode material is lithium metal anode material, which is evaluated to have even greater potential. Lithium is the lightest metal on Earth and holds the key to substantially reducing battery weight. Lithium metal anodes are hailed as the pinnacle of the next-generation anode material market because of their potential to enhance the fuel efficiency of electric vehicles.

POSCO Group has an Argentine lithium brine, which is an ideal environment for extracting high-purity lithium with minimal impurities to use as an anode material. Furthermore, it has the world’s best lithium refining technology. In addition, the independent technology accumulated with roll-to-roll processing, which produces thin lithium layers with wider widths, provides an economical and efficient solution for lithium metal anode production. POSCO Group will steadily develop these technologies to become a company that produces economically feasible lithium metal anode materials for next-generation batteries.

▼ Check POSCO Group’s anode material production competitiveness in video ↓

POSCO Group has the infrastructure and strength to produce a wide range of electrode materials, including natural and synthetic graphite, low-expansion natural graphite, silicon anode materials, and lithium metal anodes. In the future, the Group aims to establish a full portfolio to lead the electrode materials market. Stay tuned for our continued growth and advancements!